Operating Instructions, Form No. 102875, Back sheet 3 of 8

PUMP OPERATION

When operating the pump for the first time:

1. Valve and hose connections must be tight, and the reservoir or bladder must be filled to the proper fluid level. Start

the motor.

2. Jog the pump several times to build pressure.

3. Run cylinder out to its full travel several times to eliminate air from the system. For more complete instructions,

refer to the section titled “Bleeding The System” under Set-up Instructions.

4. With the cylinder(s) retracted completely, check the fluid level in the reservoir or bladder and add fluid if necessary.

Refer to “Filling The Pump Reservoir Or Bladder” under Set-up Instructions.

5. The pump is now ready to be put into regular operation.

DANGER: When lifting or lo

wering a load, the load must be under operator control at all times and

others must be clear of the load. Use blocking and cribbing to guard against a falling load.

Do not drop the load. The use of a load lowering or metering valve is recommended in

addition to the pump directional control valve.

ELECTRIC PUMP

Universal Motor: The universal motor is wired for 115 or 230 volts, 50/60 cycles according to the customer's

request. This motor cannot be rewired.

TEFC and DC Motor

s: See pump data plate for voltage, frequency, current, and power specifications.

If rewired, retesting may be required per local directives and standards. PR10 series

pump voltage is 12 VDC and is not

changeable.

1. Place the valve in neutral position.

2. Plug in the pump.

3. Start the pump and shift as required.

4. Turn the pump off when not in use.

Note: For specific function of your pump see the “Valve Options” section of this form.

IMPORTANT:

• Correct voltage is required for the pump to operate properly.

■■

Low voltage may cause: overheated motor; motor fails to start under load; motor

surging when trying to start; or motor stalls before maximum pressure is reached.

■■

Check the voltage rating on the pump motor name plate to be certain the outlet or power source you

are using is of the proper voltage.

■■

Always check the voltage at the motor with the pump running at full pressure.

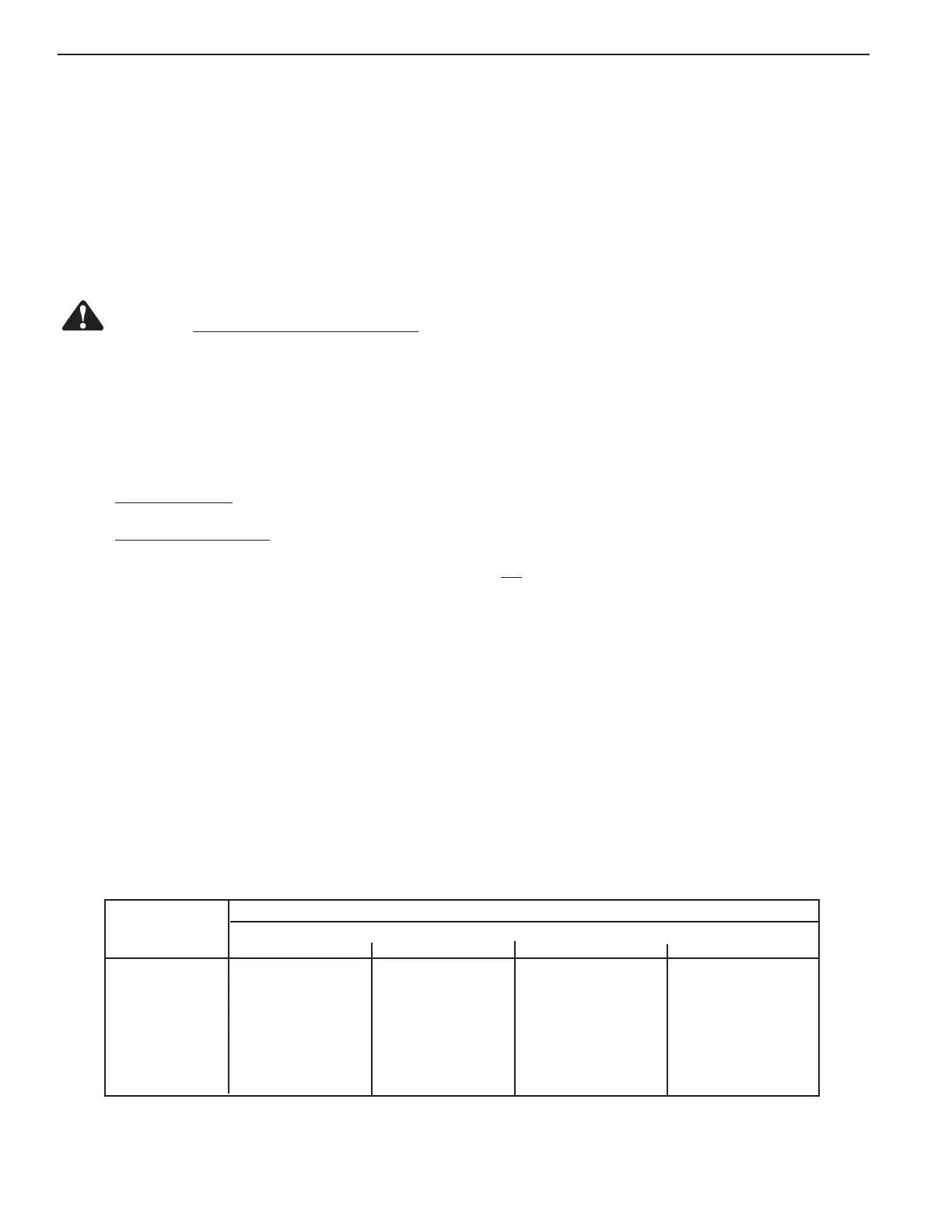

• Never run the motor on long, light gauge extension cords. Refer to the minimum recommended gauge

chart below.

Electrical Cord Size AWG (mm

2

) 3.2 Volt Drop

AMPS

At Maximum Length of Electrical Cord

Hyd. Pressure 0-25 ft. (0-8 m) 25-50 ft. (8-15 m) 50-100 ft. (15-30 m) 100-150 ft. (30-46 m)

6 18 (.82) 16 (1.33) 14 (2.09) 12 (3.32)

10 18 (.82) 14 (2.09) 12 (3.32) 10 (5.37)

14 16 (1.33) 12 (3.32) 10 (5.37) 8 (8.37)

18 14 (2.09) 12 (3.32) 8 (8.37) 8 (8.37)

22 14 (2.09) 10 (5.37) 8 (8.37) 6 (13.30)

26 12 (3.32) 10 (5.37) 8 (8.37) 6 (13.30)

30 12 (3.32) 10 (5.37) 6 (13.30) 4 (21.29)

Loading...

Loading...