SECTION FOUR – Routine Maintenance and Professional Servicing

NN

NN

OO

OO

TT

TT

EE

EE

::

::

• Take care to keep the Manifold O-ring sealing sur-

faces clean, replace the O-ring, and position it prop-

erly when reassembling.

• Lubricate the O-rings with Parker O-Ring Lube for

easy installation.

• If you are replacing a cast iron manifold/adapter

with a one-piece Inlet/Outlet Manifold, purchase

Part No. 77707-0014 (model SR/SRC200), 77707-

0015 (SR/SRC333), or 77707-0016 (SR/SRC400)

complete with safety switches. Do not reuse the

safety switches from the cast-iron adapter; the new

manifold uses some different switches. See Figure

4-5 for switch locations in the new manifold.

• If you are replacing a one-piece manifold, you can

purchase a manifold complete with safeties or you

can purchase the shell and necessary components

and transfer the safety switches to the new mani-

fold. See Figure 4 -5 for switch locations. If you

transfer the old switches, BE SURE that they are all

in good working condition before putting them in

the new manifold.

• See Figure 4-6 for switch cover installation

instructions.

• Have a No. 77707-0008 Insulation Kit on hand in

case the heating coil shifts during manifold installa-

tion and requires opening the combustion chamber

cover to realign it.

MM

MM

aa

aa

nn

nn

ii

ii

ff

ff

oo

oo

ll

ll

dd

dd

RR

RR

ee

ee

aa

aa

ss

ss

ss

ss

ee

ee

mm

mm

bb

bb

ll

ll

yy

yy

NN

NN

OO

OO

TT

TT

EE

EE

::

::

Make sure that the Baffle Plate, Insert, and

Bottom Plate are correct for your heater. The part num-

ber is molded on. Check the Water System Repair Parts

List and Exploded View, Page 5-4, to verify part num-

bers. The number is not molded on some inserts for

200K heaters.

1. Install the Internal Bypass Valve in the Manifold.

2. Install the Baffle Plate in the Manifold.

3. Install the Insert and Bottom Plate (with the

Manifold O-ring) in the Manifold. You will have to

tap them together with a rawhide or plastic mallet.

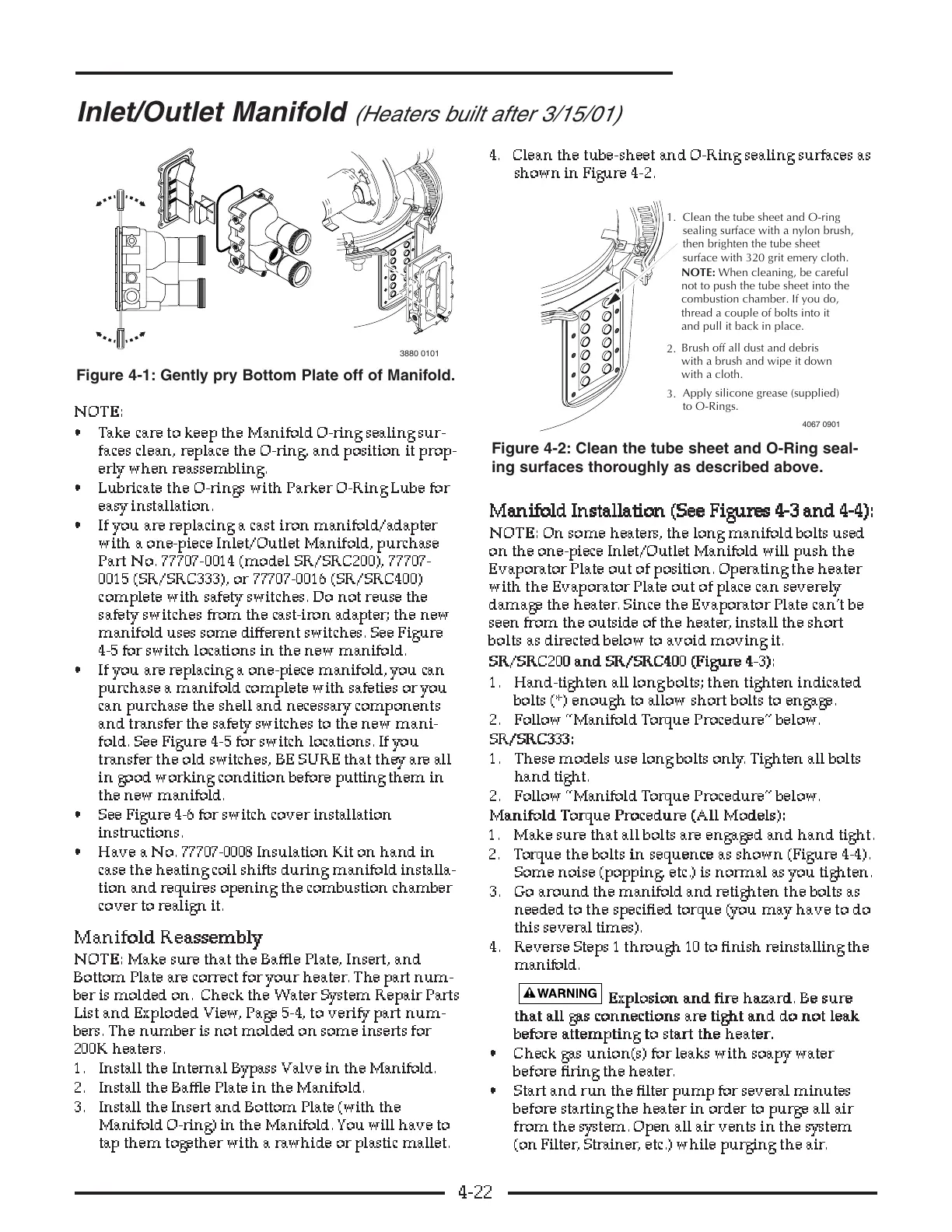

4. Clean the tube-sheet and O-Ring sealing surfaces as

shown in Figure 4-2.

MM

MM

aa

aa

nn

nn

ii

ii

ff

ff

oo

oo

ll

ll

dd

dd

II

II

nn

nn

ss

ss

tt

tt

aa

aa

ll

ll

ll

ll

aa

aa

tt

tt

ii

ii

oo

oo

nn

nn

((

((

SS

SS

ee

ee

ee

ee

FF

FF

ii

ii

gg

gg

uu

uu

rr

rr

ee

ee

ss

ss

44

44

--

--

33

33

aa

aa

nn

nn

dd

dd

44

44

--

--

44

44

))

))

::

::

NN

NN

OO

OO

TT

TT

EE

EE

::

::

On some heaters, the long manifold bolts used

on the one-piece Inlet/Outlet Manifold will push the

Evaporator Plate out of position. Operating the heater

with the Evaporator Plate out of place can severel y

damage the heater. Since the Evaporator Plate can’t be

seen from the outside of the heater, install the short

bolts as directed below to avoid moving it.

SS

SS

RR

RR

//

//

SS

SS

RR

RR

CC

CC

22

22

00

00

00

00

aa

aa

nn

nn

dd

dd

SS

SS

RR

RR

//

//

SS

SS

RR

RR

CC

CC

44

44

00

00

00

00

((

((

FF

FF

ii

ii

gg

gg

uu

uu

rr

rr

ee

ee

44

44

--

--

33

33

))

))

::

::

1. Hand-tighten all long bolts; then tighten indicated

bolts (*) enough to allow short bolts to engage.

2. Follow “Manifold Torque Procedure” below.

SS

SS

RR

RR

//

//

SS

SS

RR

RR

CC

CC

33

33

33

33

33

33

::

::

1. These models use long bolts only. Tighten all bolts

hand tight.

2. Follow “Manifold Torque Procedure” below.

MM

MM

aa

aa

nn

nn

ii

ii

ff

ff

oo

oo

ll

ll

dd

dd

TT

TT

oo

oo

rr

rr

qq

qq

uu

uu

ee

ee

PP

PP

rr

rr

oo

oo

cc

cc

ee

ee

dd

dd

uu

uu

rr

rr

ee

ee

((

((

AA

AA

ll

ll

ll

ll

MM

MM

oo

oo

dd

dd

ee

ee

ll

ll

ss

ss

))

))

::

::

1. Make sure that all bolts are engaged and hand tight.

2. Torque the bolts ii

ii

nn

nn

ss

ss

ee

ee

qq

qq

uu

uu

ee

ee

nn

nn

cc

cc

ee

ee

as shown (Figure 4-4).

Some noise (popping, etc.) is normal as you tighten.

3. Go around the manifold and retighten the bolts as

needed to the specified torque (you may have to do

this several times).

4. Reverse Steps 1 through 10 to finish reinstalling the

manifold.

EE

EE

xx

xx

pp

pp

ll

ll

oo

oo

ss

ss

ii

ii

oo

oo

nn

nn

aa

aa

nn

nn

dd

dd

ff

ff

ii

ii

rr

rr

ee

ee

hh

hh

aa

aa

zz

zz

aa

aa

rr

rr

dd

dd

..

..

BB

BB

ee

ee

ss

ss

uu

uu

rr

rr

ee

ee

tt

tt

hh

hh

aa

aa

tt

tt

aa

aa

ll

ll

ll

ll

gg

gg

aa

aa

ss

ss

cc

cc

oo

oo

nn

nn

nn

nn

ee

ee

cc

cc

tt

tt

ii

ii

oo

oo

nn

nn

ss

ss

aa

aa

rr

rr

ee

ee

tt

tt

ii

ii

gg

gg

hh

hh

tt

tt

aa

aa

nn

nn

dd

dd

dd

dd

oo

oo

nn

nn

oo

oo

tt

tt

ll

ll

ee

ee

aa

aa

kk

kk

bb

bb

ee

ee

ff

ff

oo

oo

rr

rr

ee

ee

aa

aa

tt

tt

tt

tt

ee

ee

mm

mm

pp

pp

tt

tt

ii

ii

nn

nn

gg

gg

tt

tt

oo

oo

ss

ss

tt

tt

aa

aa

rr

rr

tt

tt

tt

tt

hh

hh

ee

ee

hh

hh

ee

ee

aa

aa

tt

tt

ee

ee

rr

rr

..

..

• Check gas union(s) for leaks with soapy water

before firing the heater.

• Start and run the filter pump for several minutes

before starting the heater in order to purge all air

from the system. Open all air vents in the system

(on Filter, Strainer, etc.) while purging the air.

4-22

Inlet/Outlet Manifold

(Heaters built after 3/15/01)

combustion chamber. If you do,

and pull it back in place.

with a cloth.

to O-Rings.

surface with 320 grit emery cloth.

1.

2.

3.

Loading...

Loading...