SECTION FOUR – Routine Maintenance and Professional Servicing

4-23

Inlet/Outlet Manifold

(Heaters built after 3/15/01)

SS

SS

aa

aa

ff

ff

ee

ee

tt

tt

yy

yy

PP

PP

rr

rr

ee

ee

cc

cc

aa

aa

uu

uu

tt

tt

ii

ii

oo

oo

nn

nn

ss

ss

::

::

• Start and run the filter pump for several minutes

before starting the heater in order to purge all air

from the system. Open all air vents in the system

(on Filter, Strainer, etc.) while purging the air. Run

the pump with the vents open until all vents run a

solid stream of water.

• Check gas union(s) for leaks with soapy water

before firing the heater.

Explosion and fire hazard. Be sure

that all gass connections are tight and do not

leak before attempting to start the heater.

• See Figure 4-5 for switch cover installation

instructions.

• Have a No. 77707-0008 Insulation Kit on hand in

case the heating coil shifts during manifold installa-

tion and requires opening the combustion chamber

cover to realign it.

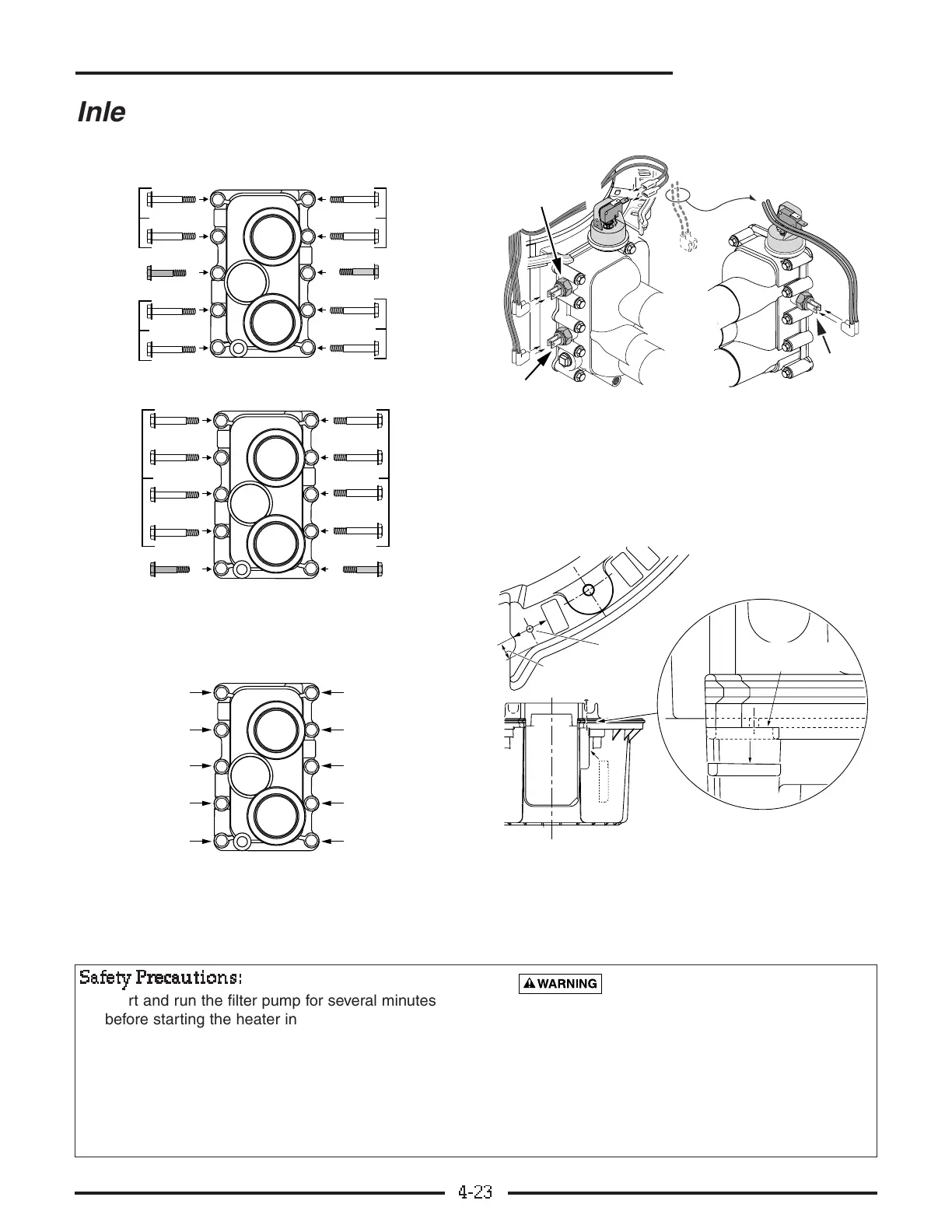

Figure 4-3: Short bolt placement. Models

SR333/SRC333 use all long bolts.

Figure 4-4: Manifold Installation: Torque sequence.

You may have to retighten the bolts several times

to achieve the necessary torque.

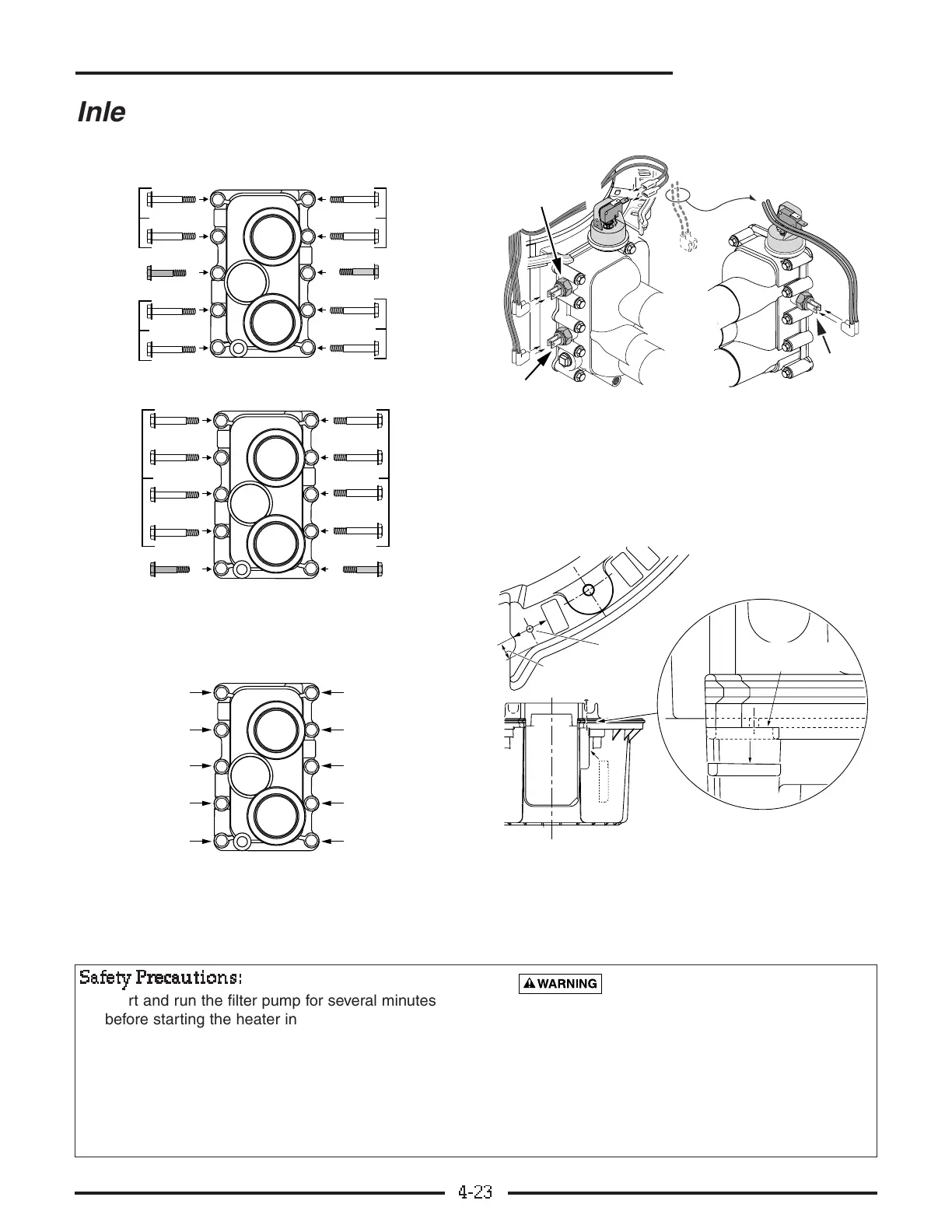

Figure 4-5 Safety switch locations on the one-piece

manifold. When replacing a cast-iron adapter, move

the AGS from the opposite side. Be sure to route

wires around pressure switch as shown (to keep

them away from the combustion chamber top).

Loading...

Loading...