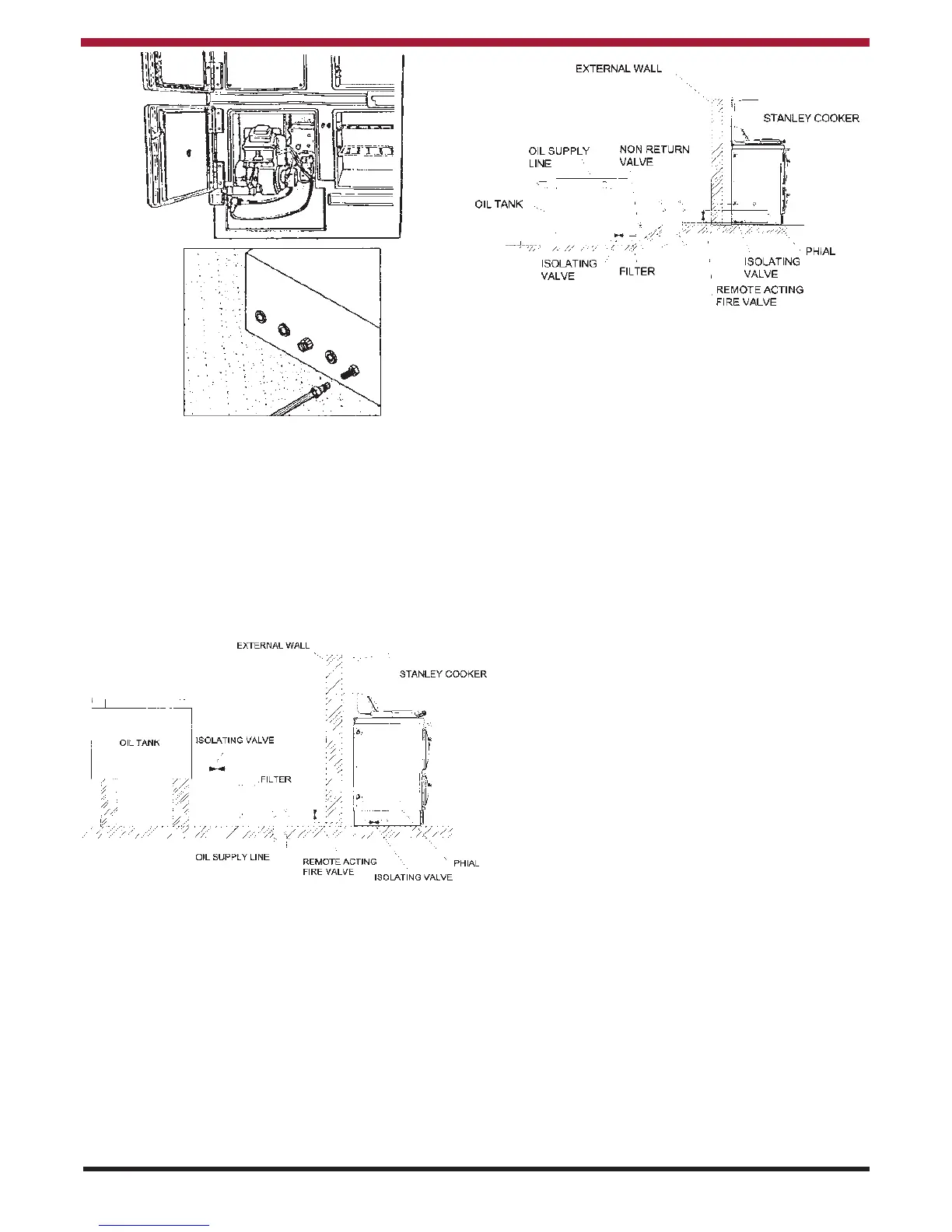

SINGLE PIPE SUPPLY SYSTEM:

BOTTOM OF OIL STORAGE TANK ABOVE

BURNER (See fig. 32)

Single pipe supply system: Tanks servicing this

appliance by means of a single pipe need to be

positioned so that they will apply the minimum head

required 1 meter (3’ 3”) of oil to the burner when the

fuel level is at its lowest point.

Refer to B.S. 5410 to calculate the additional head

requirement relating to pipe length and size.

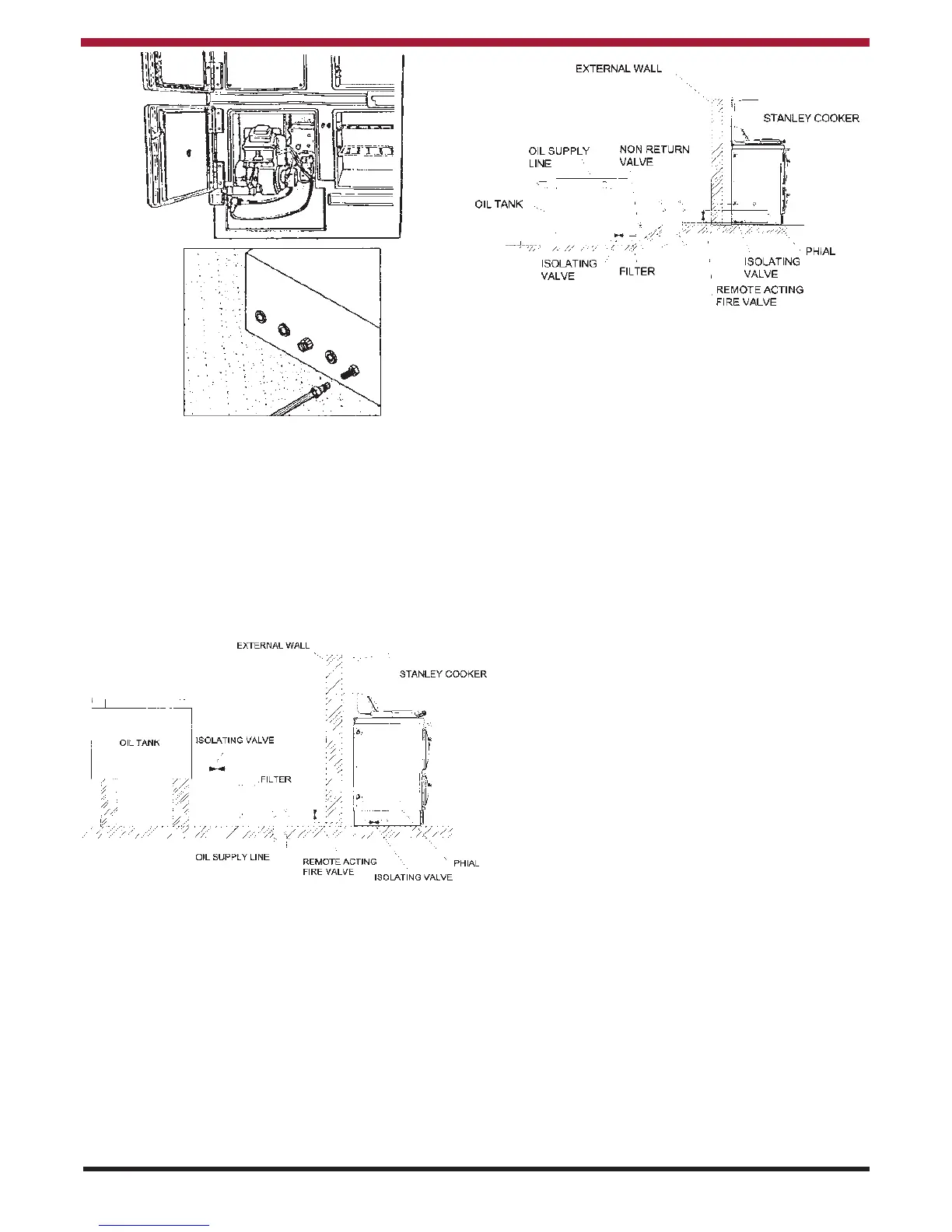

TWO PIPE SUPPLY SYSTEM:

BOTTOM OF OIL STORAGE TANK BELOW OR

LEVEL WITH BURNER (see fig. 33)

If the tank base is below the level at which the

gravity feed to the burner can be maintained, a two

pipe oil supply system may be adopted. (See fig.

33). The non-return valve in the supply line of the

two pipe system is required to prevent oil running

back from the burner and unpriming the oil pump.

The non-return valve in the return line is only

required if the top of the tank is above the burner. Its

purpose is to prevent oil running back through the

burner during maintenance.

Fig.32

Fig.30

Fig.31

SINGLE PIPE SYSTEM: WITH

DE-AERATION DEVICE BOTTOM OF OIL

STORAGE TANK BELOW OR LEVEL WITH

BURNER. (see fig. 34):

This system can be used where the tank base is

below the level at which gravity feed to the burner

can be maintained and the burner incorporates an

oil pump. The chamber is fitted close to the burner

and is linked to the tank by a single pipe, thus saving

the return pipe required by the two pipe system as

described previously. Any air in the oil brought up

from the tank is bled off in the de-aeration chamber.

De-aeration chambers must always be installed

externally to buildings because they emit small

quantities of vapour. The chamber is connected to

the oil pump in the burner of the appliance by a

normal two pipe loop.

TIGER LOOP OIL SUPPLY (see fig. 35)

F

or installations normally requiring a two pipe

system but have long or difficult return line runs, an

alternative Tigerloop Deaerator system can be used.

Tigerloop Deaerators remove air from a two pipe oil

feed. Higher lift heights can be achieved than are

possible with a conventional two pipe system.

These requirements are fully explained within the

following documents:

* B.S. 5410: Part 1: Code of Practice for Oil

firing installations up to 45 kW output capacity

for space heating and hot water supply

purposes.

* OFTEC - Technical Information Book Three.

Installation requirements for oil fired boiler and

oil storage tanks.

* The Building Regulations Part J: Ireland Part F

Section 4 Scotland and Part L Northern Ireland.

* The Building Regulations Part J: England &

Wales.

25

Fig.33

Loading...

Loading...