26

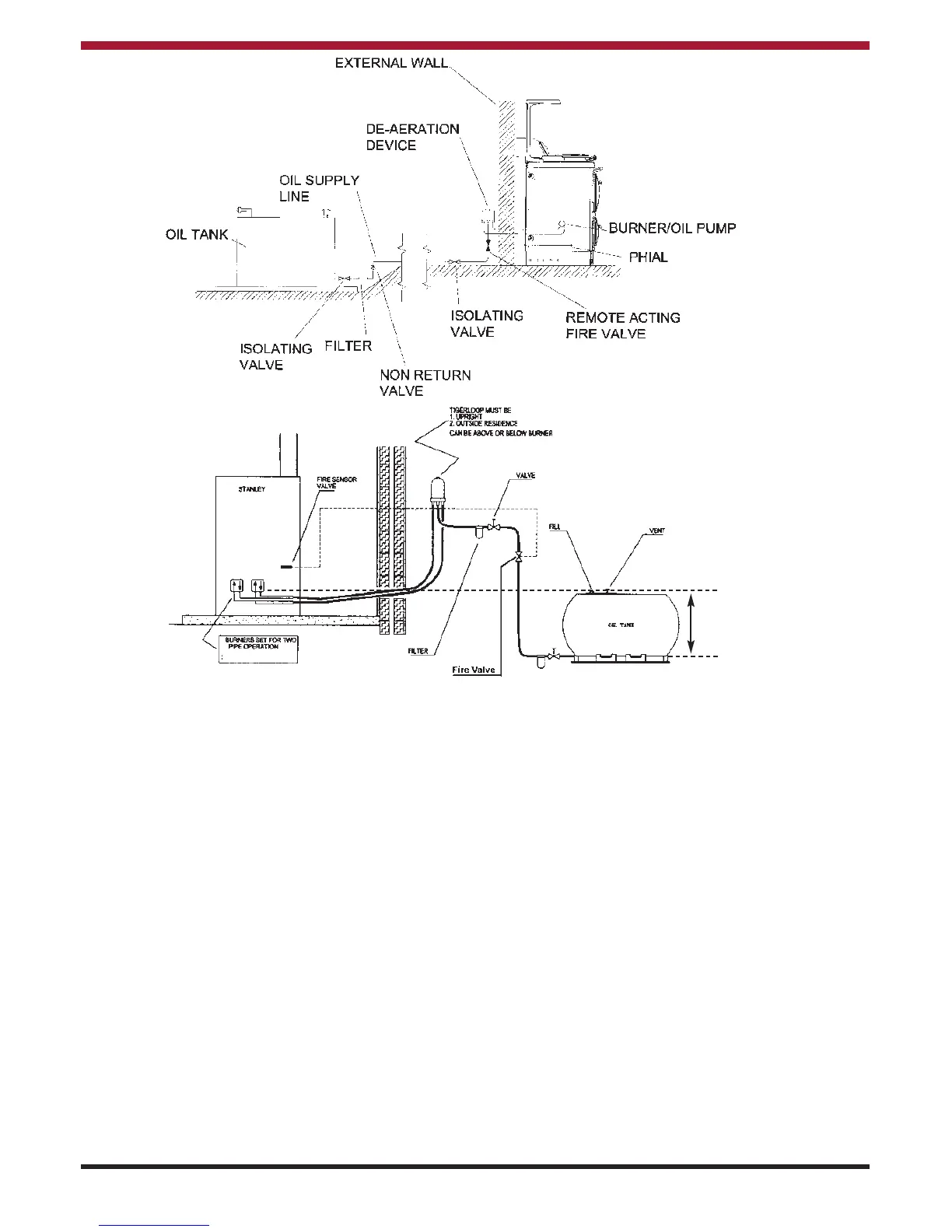

Fig. 35

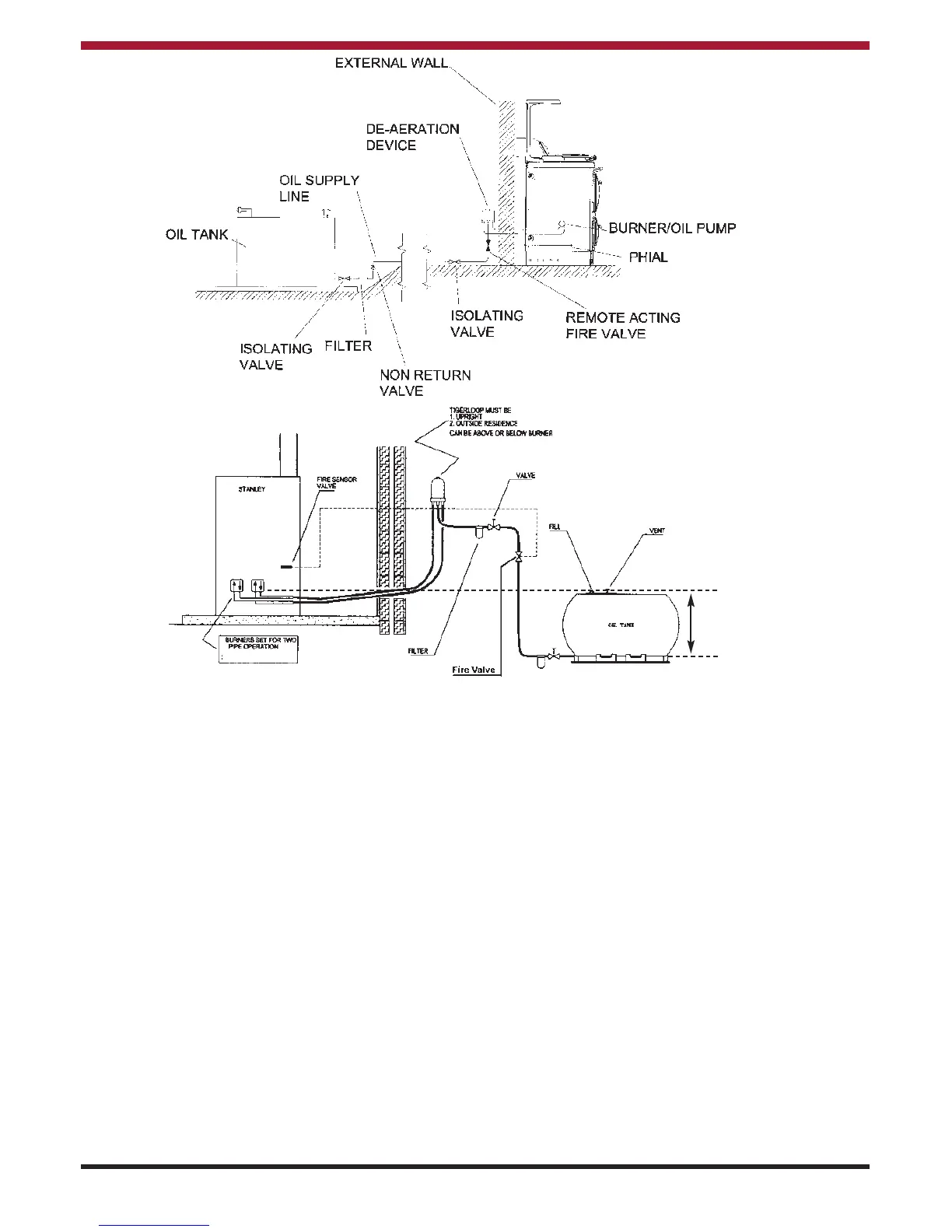

Fig. 34

INSTALLATION CHECK LIST

1. Check all items from packaging are removed

from ovens and the shelves are properly fitted.

2. Check that electrical wiring is correct.

3. Check that the boiler and heating system is full

of water and purged of air.

4. Check that the boiler plate transport screws

have been removed and that the plates are in

their correct positions. (See section removal of

transport screw and Fig. 41)

5. Time switches and room thermostats must be

on.

6. Check that all valves in the oil line are open and

that the filter is purged of air. Check that the fire

valve is open.

7. Turn on the electrical supply and check that any

time switches are on and room thermostats

associated with the cooker are on and calling for

heat. Burners should now fire.

8. Check that the interstat connection has been

wired directly to a motorised valve. This is done

by turning off room thermostats, time switches

and temporarily linking terminals 6 & 9. This

should bring on a motorised valve which will

then call the boiler.

Note: When the interstat calls; normally the

motorised valve will open, but the burner will not

operate as the supply to No.6 will be disabled.

9. Check temperature differential between flow

and return 11°C (20°F) and adjust pump or by-

pass accordingly.

10. Check heating circuit and balance if necessary.

11. With fuel supply off, switch on the burners.

12. Complete the start sequence to lockout (8

seconds) for both burners observing the correct

operating functions.

13. Ensure both pumps are purged of air. Check

pump pressure with a calibrated pressure gauge

and adjust it as necessary. (See Figs. 36 & 37)

For further information refer to 100K and 80K

specification on page 5.

4 Meters Max.

Loading...

Loading...