22

G

B

6.2 Condensation water

Thecondensationwatermustbedrainedoffeach

daybyopeningthedrainvalve(11)(ontheoorof

thepressurevessel).

Warning!

The condensation water from the pressure ves-

sel will contain residual oil. Dispose of the con-

densation water in an environmentally compat-

ible manner at the appropriate collection point.

6.3 Safety valve (10)

Thesafetyvalvehasbeensetforthehighestpermit-

tedpressureofthepressurevessel.Itisprohibited

toadjustthesafetyvalveorremoveitsseal.Actu-

ate the safety valve from time to time to ensure that

itworkswhenrequired.Pulltheringwithsufcient

force until you can hear the compressed air being

released.Thenreleasetheringagain.

6.4 Check the oil level at regular in-

tervals

Place the compressor on a level and straight sur-

face. Unscrew the oil dipstick (Fig. 8/Item 14) by

turningit counter-clockwiseandwipe thedipstick.

Re-insertthedipstickintothelleropeningasfaras

itwillgobutdonotscrewitin.Pulloutthedipstick,

holdithorizontallyandreadofftheoillevel.Theoil

level must be between the two marks MAX and MIN

ontheoildipstick(Fig.8).

Changing the oil: Recommended hydraulic oil: SAE

15W/40 or an alternative of the same quality. It

shouldberelledforthersttimeafter100hoursof

operation.Thereaftertheoilshouldbedrainedand

relledafterevery300hoursinservice.

6.5 Changing the oil

Switch off the engine and pull the mains plug out of

thesocket.Afterreleasinganyairpressureyoucan

unscrewtheoildrainagescrew(15)fromthecom-

pressorpump.Topreventtheoilfromrunningoutin

an uncontrolled manner, hold a small metal chute

under theopening and collectthe oil ina vessel.

If the oil does not drain out completely, we recom-

mendtiltingthecompressorslightly.

Dispose of the old oil at a drop-off point for old

oil.

Whentheoilhasdrainedout,re-ttheoildrainage

screw(15).Fillnewoilthroughtheoillleropening

(14)untilitcomesuptotherequiredlevel.Thenre-

inserttheoildipstick(14).

6.6 Cleaningtheintakelter(1)

Theintakelterpreventsdustanddirtbeingdrawn

in.Itisessentialtocleanthislterafteratleasteve-

ry100hoursinservice.Acloggedintakelterwill

decrease the compressor’s performance dramati-

cally. Remove the lter from the compressor and

undothethumbscrewontheairlter.Youcanthen

removethelterfromthetwohalvesoftheplastic

housing, tap it to remove the dirt, blast it down with

low-pressurecompressedair(approx.3bar)andre-

insertit.(Fig.9)

6.7 Storage

Warning!

Pull the mains plug out of the socket and venti-

late the appliance and all connected pneumatic

tools. Switch off the compressor and make sure

that it is secured in such a way that it cannot be

started up again by any unauthorized person.

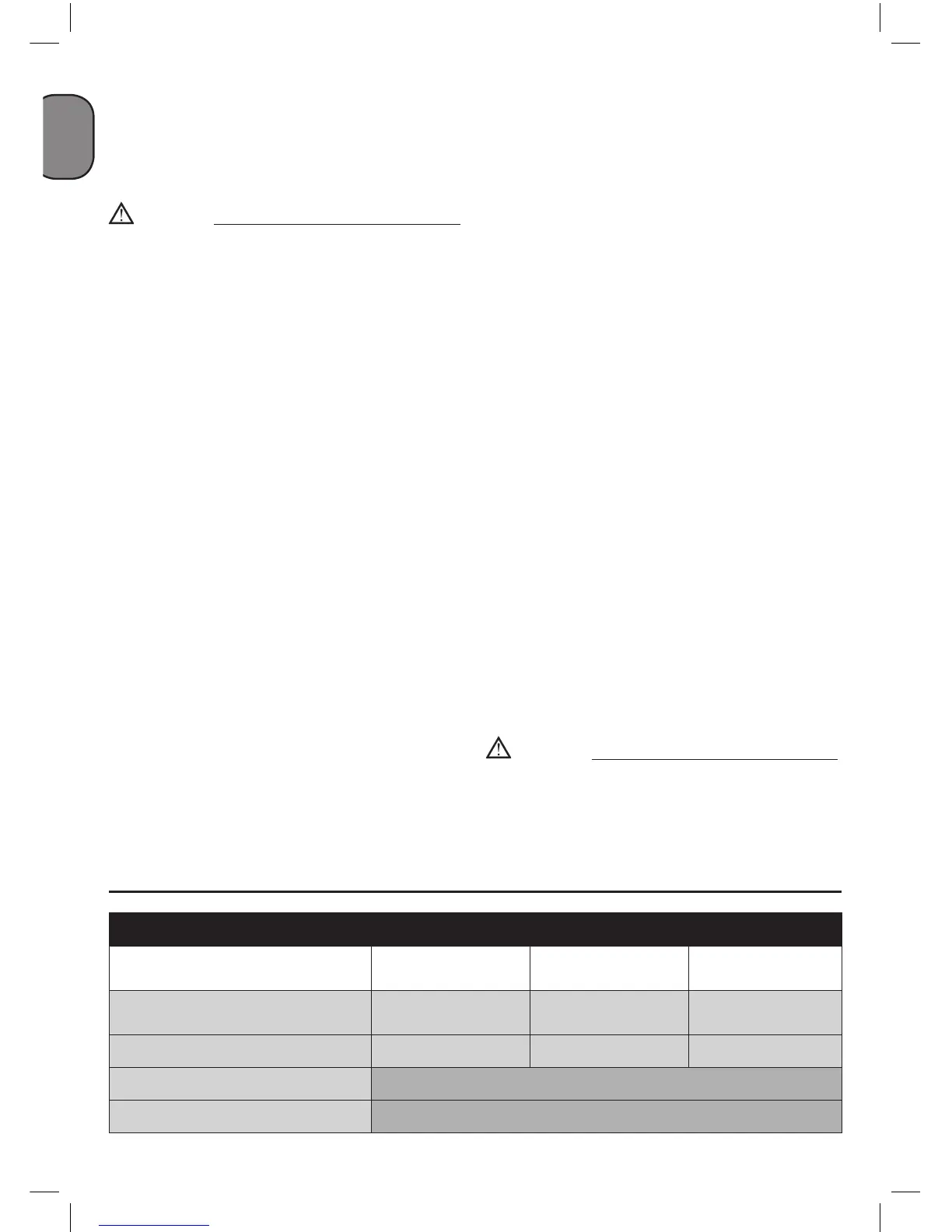

MAINTENANCE RESUMPTIVE TABLE

FUNCTION

AFTER THE FIRST

100 HOURS

EVERY 100 HOURS

EVERY 300

HOURS

Cleaning of intake filter and/or

substitution of filtering element

●

Change of oil ● ●

Tightening of head tension rods Atstart-upandafterthefirsthourofwork

Draining tank condensate Periodically and at the end of work

Loading...

Loading...