23

G

B

Warning!

Store the compressor only in a dry location

which is not accessible to unauthorized per-

sons. Always store upright, never tilted!

7. DISPOSAL AND RECYCLING

The unitand its accessories are madeof various

typesofmaterial,suchasmetalandplastic.Defec-

tive components must be disposed of as special

waste.Askyourdealeroryourlocalcouncil.

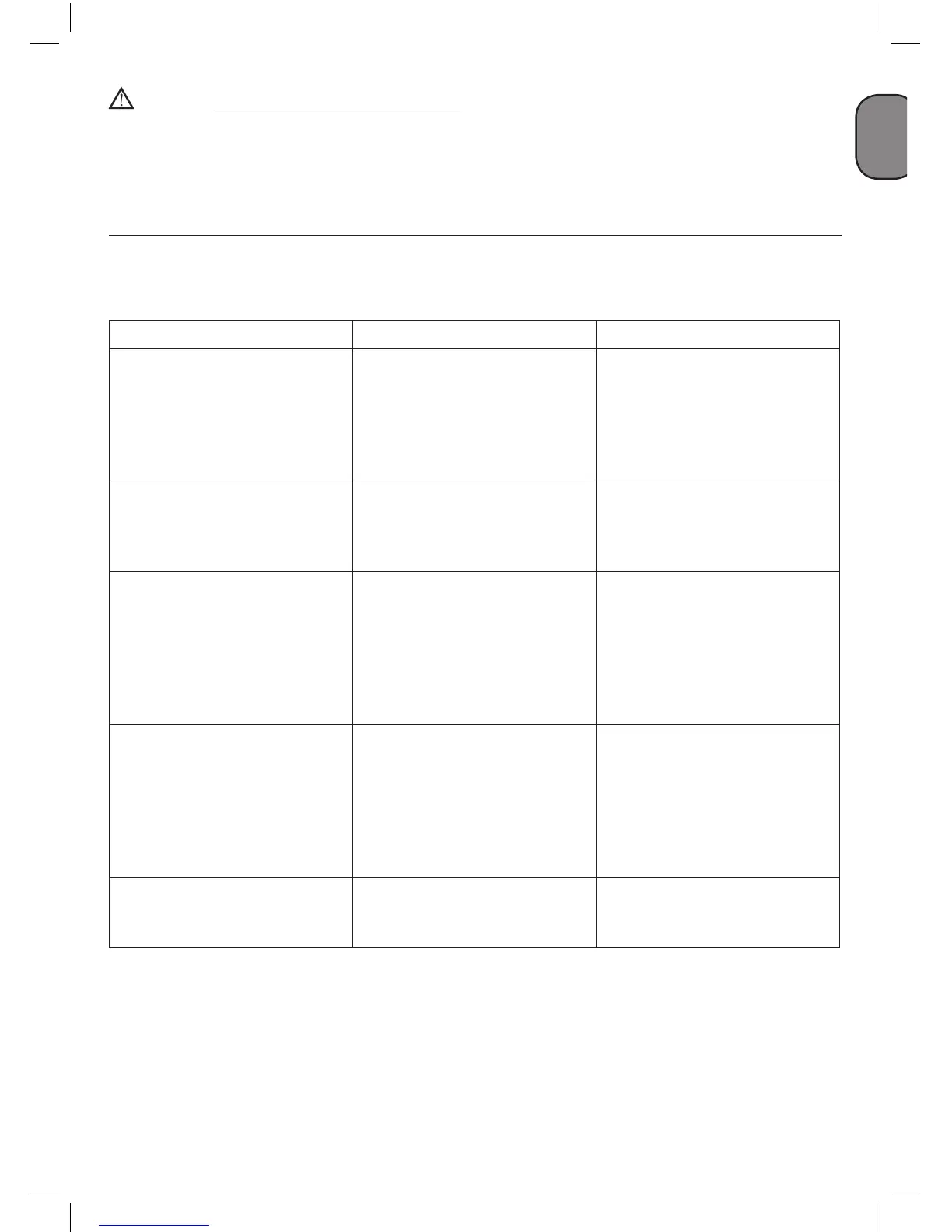

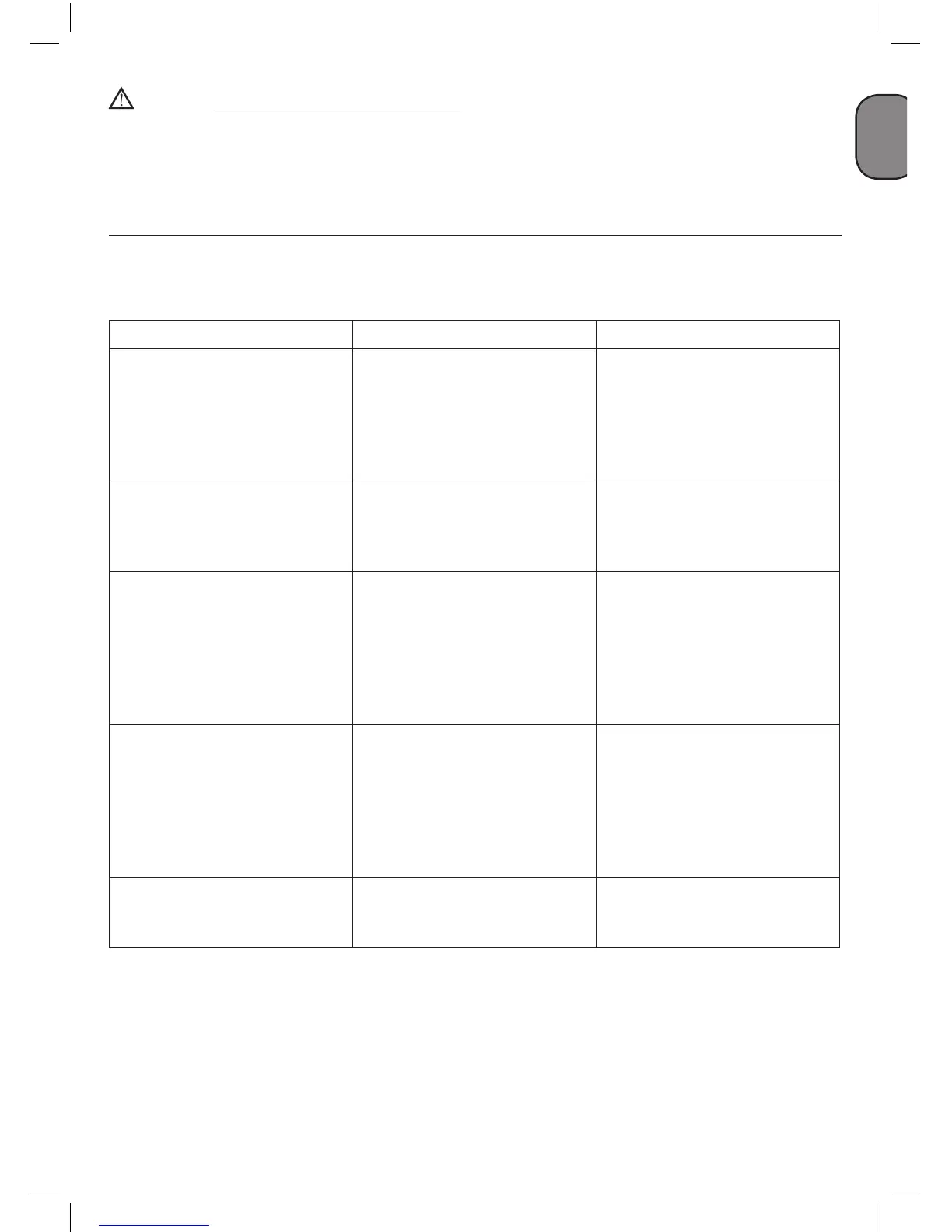

8. POSSIBLE FAULTS AND RELATED PERMITTED REMEDIES

FAULT CAUSE REMEDY

Leakage of air from the valve

of the pressure switch with the

compressoroff.

Check valve that, due to wear

or dirt on the seal, does not

performitsfunctioncorrectly.

Unscrew the hexagonal head of

the check valve, clean the valve

seat and the special rubber disk

(replaceifworn).Reassemble

andtightencarefully(gures

14-15).

Reductionofperformance.

Frequentstart-up.Lowpressure

values.

Excessive performance request,

check for any leaks from the

couplingsand/orpipes.Intake

ltermaybeclogged.

Replacethesealsofthetting,

cleanorreplacethelter.

Thecompressorstopsand

restarts automatically after a few

minutes.

In the V, 3 HP versions, it is does

notstart.

Trippingofthethermalcutout

duetooverheatingofthemotor.

Clean the air ducts in the

conveyor.Ventilatethework

area.Resetthethermalcutout.

On lubricated and V type

models, check oil level and

quality.OnVmodels,havethe

voltagechecked.

After a few attempts to restart,

thecompressor.

Trippingofthethermalcutout

due to overheating of the motor

(removaloftheplugwiththe

compressor running, low power

voltage).

Activatetheon/offswitch.

Ventilatetheworkarea.Waita

fewminutes.Thecompressor

willrestartindependently.OnV,

3 HP models, reset the thermal

cutout.Removeanypowercable

extensions.

Thecompressordoesnotstop

andthesafetyvalveistripped.

Irregular functioning of the

compressor or breakage of the

pressureswitch.

Remove the plug and contact

theServiceCenter.

Any other type of operation must be carried out by authorized Service Centers, requesting original

parts. Tampering with the machine may impair its safety and in any case make the warranty null

and void.

Loading...

Loading...