MAINTENANCE

Connections

Connectionson pressurewasherhoses,gunandspraywandshouldbe

cleanedregularlyandlubricatedwith non-watersolublegrease.

Adjustable Nozzle Maintenance

Surging,orpulsingsensation,felt while squeezingthe spraygun

triggermaybecausedby excessivepumppressure.Theprincipal

causeof excessivepumppressureis anozzlecloggedor restricted

with foreignmaterials,suchasdirt, etc.Tocorrectthe problem,

immediatelycleanthe nozzleusingthetoolsincludedwith your

pressurewasherandfollow theseinstructions:

1. Shutoff pressurewasherandturnoff water supply.

2. Depressurizeunitby squeezingtriggerwith wand awayfrom

face.

3. Removewandfromgun

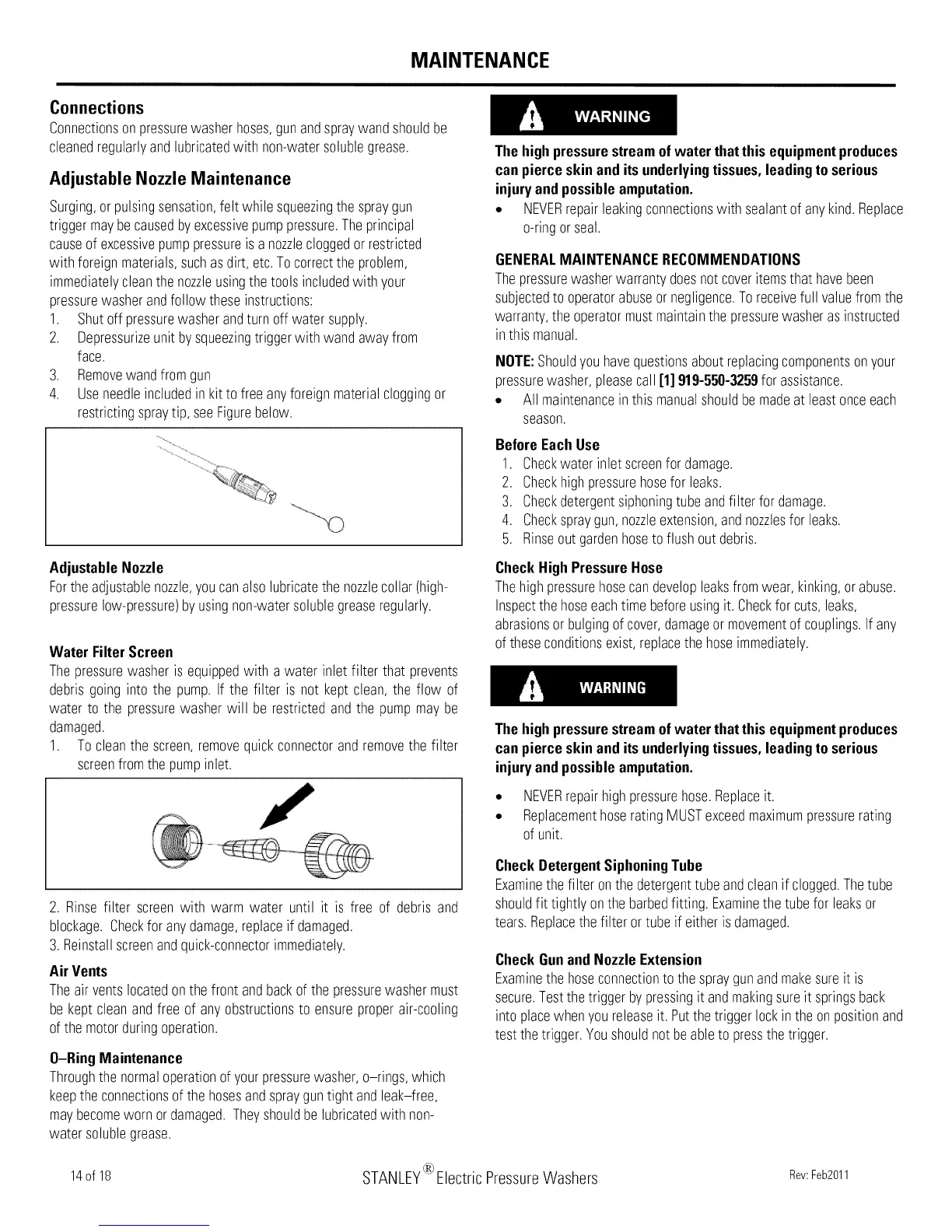

4. Useneedleincludedin kit tofree anyforeignmaterialcloggingor

restrictingspraytip, seeFigurebelow.

AdjustableNozzle

Fortheadjustablenozzle,you canalsolubricatethe nozzlecollar(high-

pressurelow-pressure)byusingnon-watersolublegreaseregularly.

Water FilterScreen

Thepressurewasher is equippedwith a water inletfilter that prevents

debrisgoing into the pump.If the filter is not kept clean,the flow of

water to the pressurewasherwill be restrictedandthe pumpmaybe

damaged.

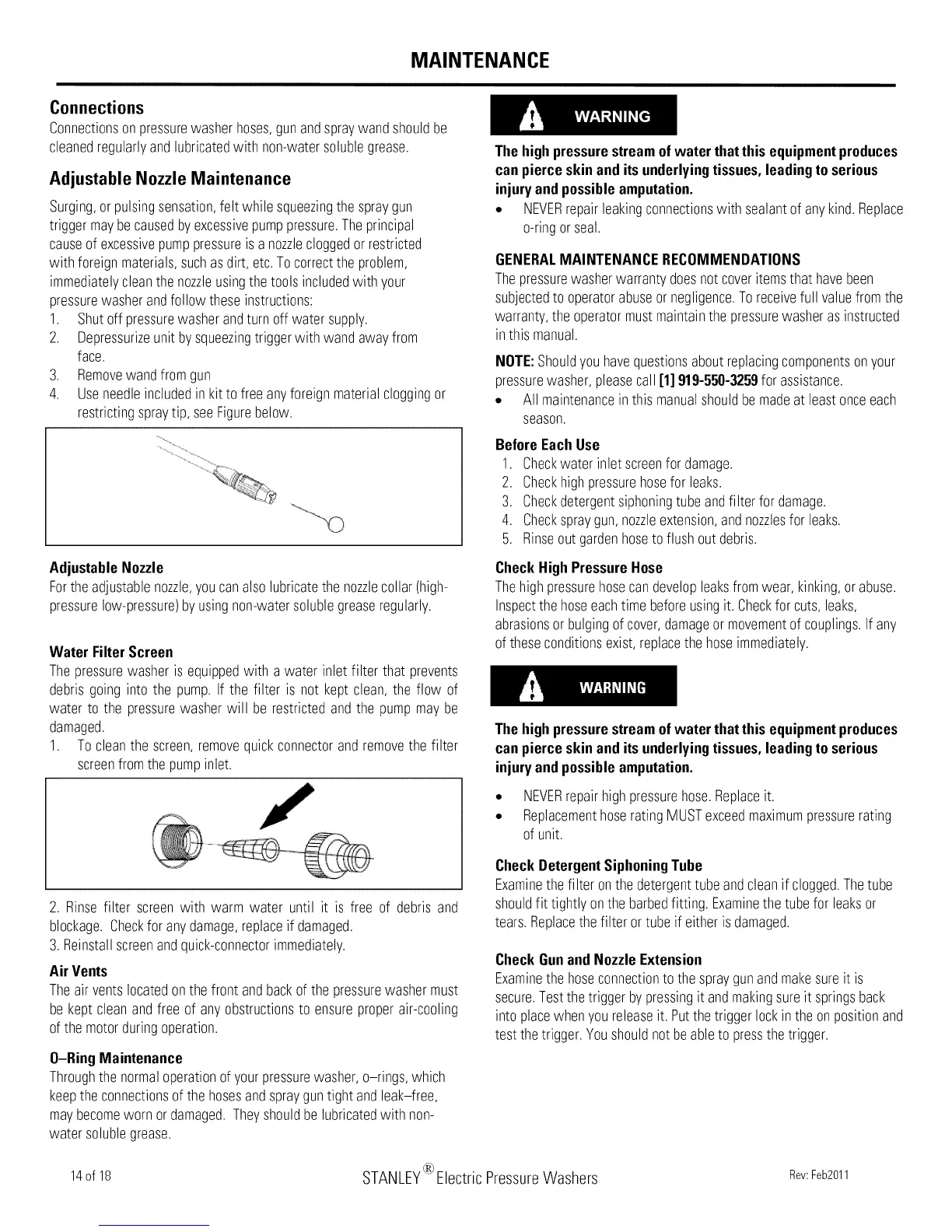

1. Tocleanthe screen,removequickconnectorandremovethe filter

screenfromthepumpinlet.

Thehighpressurestreamofwater thatthis equipmentproduces

canpierce skin andits underlyingtissues,leadingto serious

injuryand possibleamputation.

• NEVERrepairleakingconnectionswith sealantof anykind.Replace

o-ringor seal.

GENERALMAINTENANCERECOMMENDATIONS

Thepressurewasherwarrantydoesnotcoveritemsthat havebeen

subjectedto operatorabuseor negligence.Toreceivefull valuefromthe

warranty,theoperatormustmaintainthe pressurewasherasinstructed

inthis manual.

NOTE:Shouldyouhavequestionsaboutreplacingcomponentsonyour

pressurewasher,pleasecall[1] 919-550-3259for assistance.

• All maintenancein thismanualshouldbemadeat leastonceeach

season.

BeforeEachUse

1. Checkwater inlet screenfor damage.

2. Checkhighpressurehosefor leaks.

3. Checkdetergentsiphoningtubeandfilter for damage.

4. Checkspraygun,nozzleextension,andnozzlesfor leaks.

5. Rinseout gardenhoseto flushout debris.

CheckHighPressureHose

Thehighpressurehosecandevelopleaksfromwear,kinking,or abuse.

Inspectthehoseeachtimebeforeusingit. Checkforcuts,leaks,

abrasionsor bulgingof cover,damageor movementof couplings.If any

oftheseconditionsexist,replacethehoseimmediately.

Thehighpressurestreamofwater that this equipmentproduces

canpierce skin andits underlyingtissues,leadingto serious

injuryand possibleamputation.

• NEVERrepairhighpressurehose.Replaceit.

• ReplacementhoseratingMUSTexceedmaximumpressurerating

ofunit.

2. Rinsefilter screenwith warm water until it is free of debrisand

blockage.Checkfor anydamage,replaceif damaged.

3.Reinstallscreenandquick-connectorimmediately.

Air Vents

Theairventslocatedonthe front andbackof the pressurewashermust

bekept cleanand free of anyobstructionsto ensureproperair-cooling

ofthe motorduringoperation.

0-Ring Maintenance

Throughthe normaloperationofyourpressurewasher,o-rings,which

keeptheconnectionsof the hosesandsprayguntight andleak-free,

maybecomeworn ordamaged.Theyshouldbelubricatedwith non-

water solublegrease.

CheckDetergentSiphoningTube

Examinethefilter onthe detergenttubeandcleanif clogged.Thetube

shouldfit tightlyonthe barbedfitting. Examinethe tubefor leaksor

tears.Replacethefilter ortube if either is damaged.

CheckGunandNozzle Extension

Examinethe hoseconnectionto thespraygunandmakesureit is

secure.Testthe triggerbypressingit andmakingsureit springsback

intoplacewhen youreleaseit. Putthe triggerloci<intheon positionand

testthe trigger.Youshouldnotbeableto pressthetrigger.

®

14of18 STANLEYi Electric PressureWashers Rev:Feb2011

Loading...

Loading...