Handle assembly (Fig D)

Place washer (e), housing (b), washer (c) and hex nut (d) on

the bolt (a) to assemble the handle (11)

uprights. Note that Part 2 should be positioned as shown in

Fig. B4. Connect Part 4 (top cross support) to the top of the

frame. Note that Part 4 should be positioned as shown in

Fig. B4.

Step 4

Now place and connect the ends of the top and center frame

supports to the frame. Take care to ensure that the supports

are positioned as shown in Fig. B5.

Step 5

Once you are satisfied that the frame is assembled correctly,

fully tighten ALL the bolts. Finally, assemble the 4 foot pads to

the bottom of each leg (see Fig. B6).

2. Assemble the stand’s legs

Step 1

Select the following parts:

2 x Part 1

1 x Part 3

1 x Part 5

Lay the parts together as shown in Fig. B1, B2, and B3. This

is best done by simply laying the parts loosely together on the

floor. Once you are satisfied that you have the parts correctly

laid together, start the fitting process.

Align the holes and secure with the bolts as shown in

Fig. B1.

DO NOT fully tighten the bolts, nuts and washers at this point.

Finger tight is sufficient.

Step 2

Repeat Step 1 so that there are two frames assembled.

Step 3

Select the following parts:

2 x Part 2

2 x Part 4

These will form the crosspieces between the previously

assembled frames. Lay the parts flat on the floor. Connect the

longer Part (2) and fix it to the frame in the center of the

B1

B2

B3

B1

5

3

2

4

B4

1

B6

5

1

4

B5

Handle assembly (Fig D)

Place washer (e), housing (b), washer (c) and hex nut (d) on

the bolt (a) to assemble the handle (11)

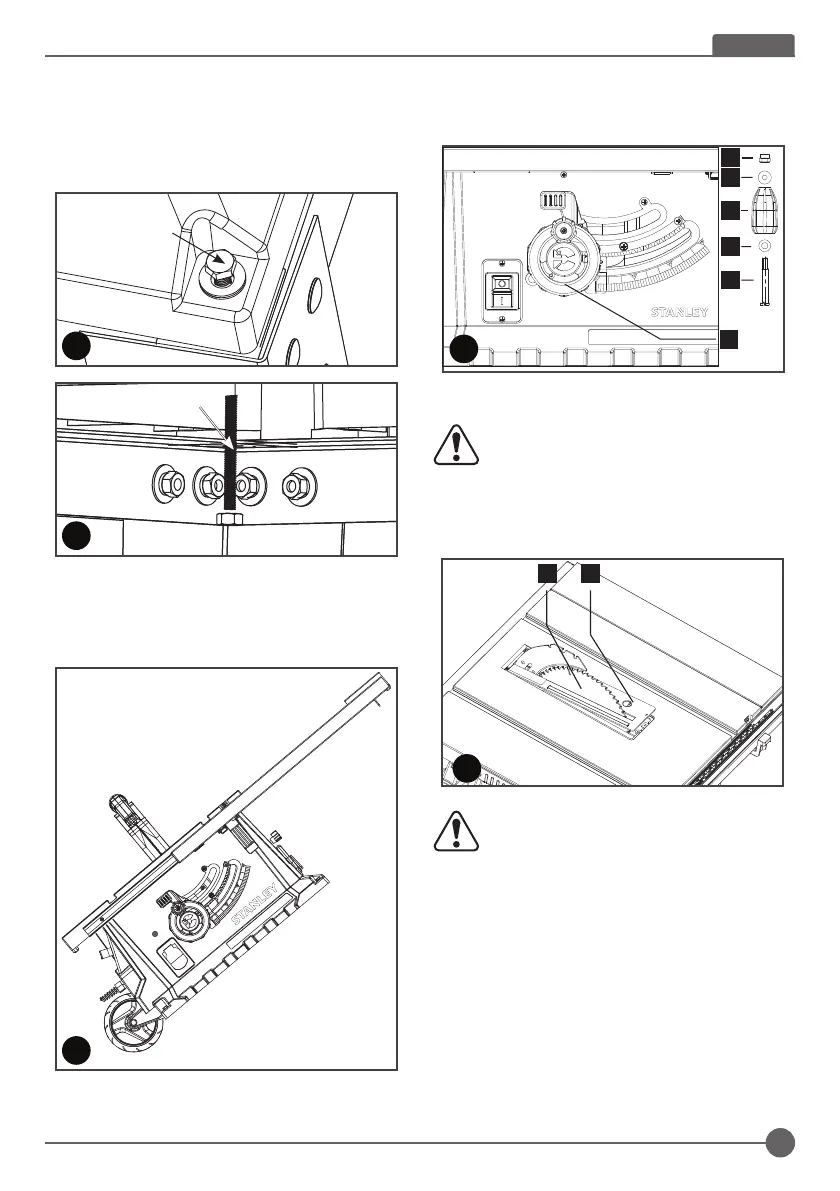

Riving knife set-up (Fig E, F, G)

WARNING! Disconnect the mains cable! The

setup of the riving knife (3) must be checked

before each use.

1. Set the saw blade (4) to the max. cutting depth, put it at 00

position and lock it

2. Remove the table insert (20) (Fig. E)

WARNING! For transport reasons, the riving

knife (3) was fixed in the lower position before

initial commissioning. Only work with the

machine if the riving knife (3) is in the upper

position. Fitting the riving knife (3) in the upper

position is as follows:

3. Loosen the locking handle (f) and push the riving knife (3)

in the upper position (Fig.F)

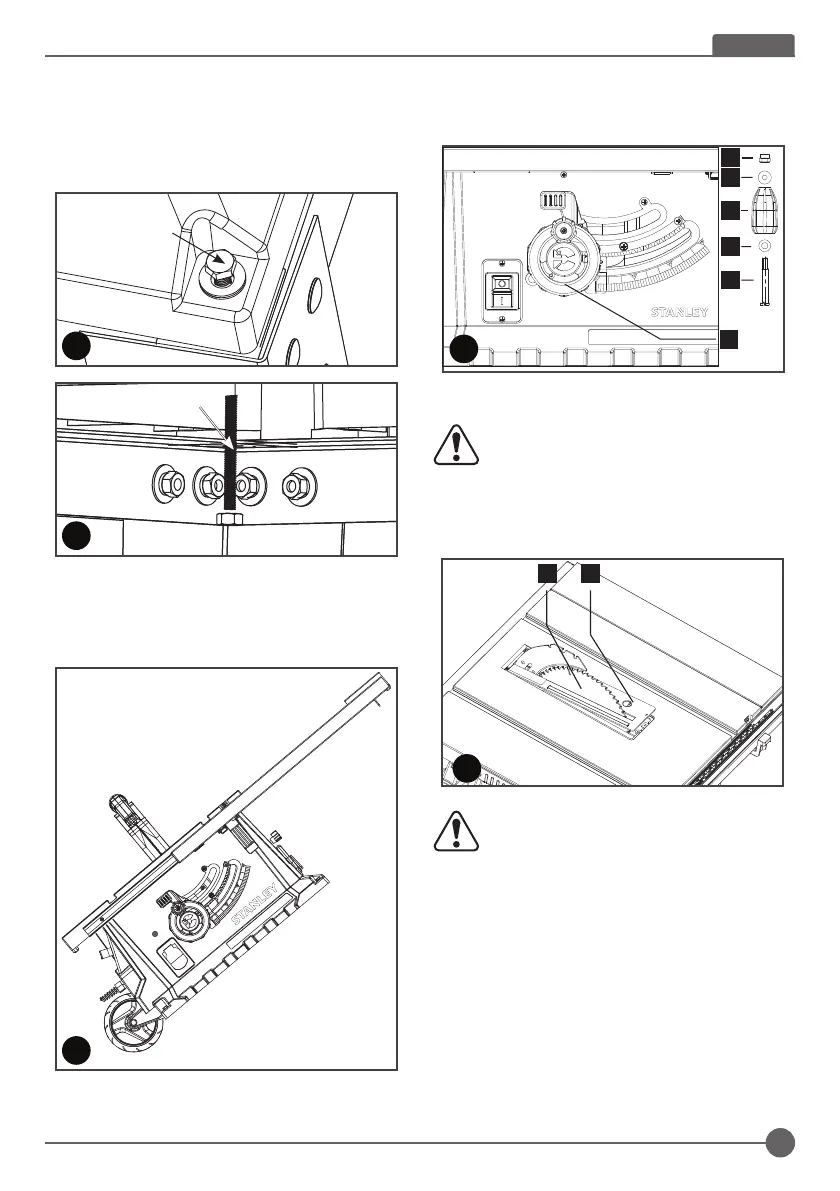

Fitting the table saw to the stand (see FIG. C1, C2)

There are four mounting holes on the base of the saw. 4

corresponding mounting holes are located on the top plane of

the stand. Put the table saw on the stand, match the holes on

the base of the saw with the holes on the stand, and secure

them with the 4 bolts (12) provided. DO fully fasten

Transportation (Fig C3)

Pull out the right side extension as the temporary handle to

transport the table saw on its wheels."

12

C1

12

C2

C3

d

c

e

a

11

D

b

Riving knife set-up (Fig E, F, G)

WARNING! Disconnect the mains cable! The

setup of the riving knife (3) must be checked

before each use.

1. Set the saw blade (4) to the max. cutting depth, put it at

00 position and lock it

2. Remove the table insert (20) (Fig. E)

uprights. Note that Part 2 should be positioned as shown in

Fig. B4. Connect Part 4 (top cross support) to the top of the

frame. Note that Part 4 should be positioned as shown in

Fig. B4.

Step 4

Now place and connect the ends of the top and center frame

supports to the frame. Take care to ensure that the supports

are positioned as shown in Fig. B5.

Step 5

Once you are satisfied that the frame is assembled correctly,

fully tighten ALL the bolts. Finally, assemble the 4 foot pads to

the bottom of each leg (see Fig. B6).

2. Assemble the stand’s legs

Step 1

Select the following parts:

2 x Part 1

1 x Part 3

1 x Part 5

Lay the parts together as shown in Fig. B1, B2, and B3. This

is best done by simply laying the parts loosely together on the

floor. Once you are satisfied that you have the parts correctly

laid together, start the fitting process.

Align the holes and secure with the bolts as shown in

Fig. B1.

DO NOT fully tighten the bolts, nuts and washers at this point.

Finger tight is sufficient.

Step 2

Repeat Step 1 so that there are two frames assembled.

Step 3

Select the following parts:

2 x Part 2

2 x Part 4

These will form the crosspieces between the previously

assembled frames. Lay the parts flat on the floor. Connect the

longer Part (2) and fix it to the frame in the center of the

B1

B2

B3

B1

5

3

2

4

B4

1

B6

5

1

4

B5

Handle assembly (Fig D)

Place washer (e), housing (b), washer (c) and hex nut (d) on

the bolt (a) to assemble the handle (11)

Riving knife set-up (Fig E, F, G)

WARNING! Disconnect the mains cable! The

setup of the riving knife (3) must be checked

before each use.

1. Set the saw blade (4) to the max. cutting depth, put it at 00

position and lock it

2. Remove the table insert (20) (Fig. E)

WARNING! For transport reasons, the riving

knife (3) was fixed in the lower position before

initial commissioning. Only work with the

machine if the riving knife (3) is in the upper

position. Fitting the riving knife (3) in the upper

position is as follows:

3. Loosen the locking handle (f) and push the riving knife (3)

in the upper position (Fig.F)

Fitting the table saw to the stand (see FIG. C1, C2)

There are four mounting holes on the base of the saw. 4

corresponding mounting holes are located on the top plane of

the stand. Put the table saw on the stand, match the holes on

the base of the saw with the holes on the stand, and secure

them with the 4 bolts (12) provided. DO fully fasten

Transportation (Fig C3)

Pull out the right side extension as the temporary handle to

transport the table saw on its wheels."

12

C1

12

C2

C3

d

c

e

a

11

D

b

204

E

WARNING! For transport reasons, the riving

knife (3) was fixed in the lower position before

initial commissioning. Only work with the

machine if the riving knife (3) is in the upper

position. Fitting the riving knife (3) in the upper

position is as follows:

3. Loosen the locking handle (f) and push the riving knife (3)

in the upper position (Fig.F)

Fitting the table saw to the stand (see FIG. C1, C2)

There are four mounting holes on the base of the saw. 4

corresponding mounting holes are located on the top plane of

the stand. Put the table saw on the stand, match the holes on

the base of the saw with the holes on the stand, and secure

them with the 4 bolts (12) provided. DO fully fasten

uprights. Note that Part 2 should be positioned as shown in

Fig. B4. Connect Part 4 (top cross support) to the top of the

frame. Note that Part 4 should be positioned as shown in

Fig. B4.

Step 4

Now place and connect the ends of the top and center frame

supports to the frame. Take care to ensure that the supports

are positioned as shown in Fig. B5.

Step 5

Once you are satisfied that the frame is assembled correctly,

fully tighten ALL the bolts. Finally, assemble the 4 foot pads to

the bottom of each leg (see Fig. B6).

2. Assemble the stand’s legs

Step 1

Select the following parts:

2 x Part 1

1 x Part 3

1 x Part 5

Lay the parts together as shown in Fig. B1, B2, and B3. This

is best done by simply laying the parts loosely together on the

floor. Once you are satisfied that you have the parts correctly

laid together, start the fitting process.

Align the holes and secure with the bolts as shown in

Fig. B1.

DO NOT fully tighten the bolts, nuts and washers at this point.

Finger tight is sufficient.

Step 2

Repeat Step 1 so that there are two frames assembled.

Step 3

Select the following parts:

2 x Part 2

2 x Part 4

These will form the crosspieces between the previously

assembled frames. Lay the parts flat on the floor. Connect the

longer Part (2) and fix it to the frame in the center of the

B1

B2

B3

B1

5

3

2

4

B4

1

B6

5

1

4

B5

Handle assembly (Fig D)

Place washer (e), housing (b), washer (c) and hex nut (d) on

the bolt (a) to assemble the handle (11)

Riving knife set-up (Fig E, F, G)

WARNING! Disconnect the mains cable! The

setup of the riving knife (3) must be checked

before each use.

1. Set the saw blade (4) to the max. cutting depth, put it at 00

position and lock it

2. Remove the table insert (20) (Fig. E)

WARNING! For transport reasons, the riving

knife (3) was fixed in the lower position before

initial commissioning. Only work with the

machine if the riving knife (3) is in the upper

position. Fitting the riving knife (3) in the upper

position is as follows:

3. Loosen the locking handle (f) and push the riving knife (3)

in the upper position (Fig.F)

Fitting the table saw to the stand (see FIG. C1, C2)

There are four mounting holes on the base of the saw. 4

corresponding mounting holes are located on the top plane of

the stand. Put the table saw on the stand, match the holes on

the base of the saw with the holes on the stand, and secure

them with the 4 bolts (12) provided. DO fully fasten

Transportation (Fig C3)

Pull out the right side extension as the temporary handle to

transport the table saw on its wheels."

12

C1

12

C2

Transportation (Fig C3)

Pull out the right side extension as the temporary handle to

transport the table saw on its wheels.

uprights. Note that Part 2 should be positioned as shown in

Fig. B4. Connect Part 4 (top cross support) to the top of the

frame. Note that Part 4 should be positioned as shown in

Fig. B4.

Step 4

Now place and connect the ends of the top and center frame

supports to the frame. Take care to ensure that the supports

are positioned as shown in Fig. B5.

Step 5

Once you are satisfied that the frame is assembled correctly,

fully tighten ALL the bolts. Finally, assemble the 4 foot pads to

the bottom of each leg (see Fig. B6).

2. Assemble the stand’s legs

Step 1

Select the following parts:

2 x Part 1

1 x Part 3

1 x Part 5

Lay the parts together as shown in Fig. B1, B2, and B3. This

is best done by simply laying the parts loosely together on the

floor. Once you are satisfied that you have the parts correctly

laid together, start the fitting process.

Align the holes and secure with the bolts as shown in

Fig. B1.

DO NOT fully tighten the bolts, nuts and washers at this point.

Finger tight is sufficient.

Step 2

Repeat Step 1 so that there are two frames assembled.

Step 3

Select the following parts:

2 x Part 2

2 x Part 4

These will form the crosspieces between the previously

assembled frames. Lay the parts flat on the floor. Connect the

longer Part (2) and fix it to the frame in the center of the

B1

B2

B3

B1

5

3

2

4

B4

1

B6

5

1

4

B5

Handle assembly (Fig D)

Place washer (e), housing (b), washer (c) and hex nut (d) on

the bolt (a) to assemble the handle (11)

Riving knife set-up (Fig E, F, G)

WARNING! Disconnect the mains cable! The

setup of the riving knife (3) must be checked

before each use.

1. Set the saw blade (4) to the max. cutting depth, put it at 00

position and lock it

2. Remove the table insert (20) (Fig. E)

WARNING! For transport reasons, the riving

knife (3) was fixed in the lower position before

initial commissioning. Only work with the

machine if the riving knife (3) is in the upper

position. Fitting the riving knife (3) in the upper

position is as follows:

3. Loosen the locking handle (f) and push the riving knife (3)

in the upper position (Fig.F)

Fitting the table saw to the stand (see FIG. C1, C2)

There are four mounting holes on the base of the saw. 4

corresponding mounting holes are located on the top plane of

the stand. Put the table saw on the stand, match the holes on

the base of the saw with the holes on the stand, and secure

them with the 4 bolts (12) provided. DO fully fasten

Transportation (Fig C3)

Pull out the right side extension as the temporary handle to

transport the table saw on its wheels."

12

C1

12

C2

C3

9

ENGLISH

Loading...

Loading...