4 5

IL1104

Water Level

25 ft.

Max

Suction

Lift

3/4 or 1 in.

Discharge Pipe

1-1/4 in.

Suction

Pipe

Discharge

to Home

Pipe

Support

Foot Valve

TYPICAL PUMP SETUP

Shallow well jet pumps are designed for use

where the suction lift is 25 feet or less. They can

be used with drilled (cased wells) (Fig. 1), dug

wells, driven wells (Fig. 2) or with cisterns or

lakes.

VENTILATION

Ventilation and drainage must be provided to

prevent damage to the motor from heat and

moisture.

FREEZING

The pump and all piping must be protected from

freezing. If freezing weather is forecast, drain

pump or remove completely from the system.

WATER SUPPLY

The water source must be able to supply enough

water to satisfy the capacity of the pump and

water needs. See performance chart on page 2.

SUCTION LIFT

Suction lift is the vertical distance from the lowest

level of the water to the pump intake. The pump

will move water as long as the pump is within 25

vertical feet of the water source.

HORIZONTAL DISTANCE

The horizontal distance is the horizontal

measurement between the pump suction and the

water source. This distance may affect the ability

of the pump to operate. If it is over 100 feet, call

the manufacturer for assistance at

1-800-742-5044.

PIPE AND FITTINGS

Use galvanized steel or NSF PW Schedule 40

PVC pipe and ttings. This material is designed

for water pressure and will seal against air and

water under pressure. Do Not Use: DWV ttings,

as these are designed for drains without pressure

and will not seal properly. (Fig. 2 & 3)

CAUTION: The entire system must be

air and water tight for efcient operation and to

maintain prime.

WIRE SIZE:

The wire size is determined by the distance from

the power source to the pump motor, and the

horsepower rating of the motor. See the wire chart

on page 11 for proper wire size.

GENERAL PUMP INFORMATION

1

L0951

IL1105

3/4 in. Discharge

1-1/4 in.

Suction

3

TOOLS REQUIRED

PREPARATION

Pipe wrenches (2)

Wire strippers

Needle-nose pliers

Phillips screwdriver

Wire cutters

Adjustable wrench

Pipe tape

Pipe dope

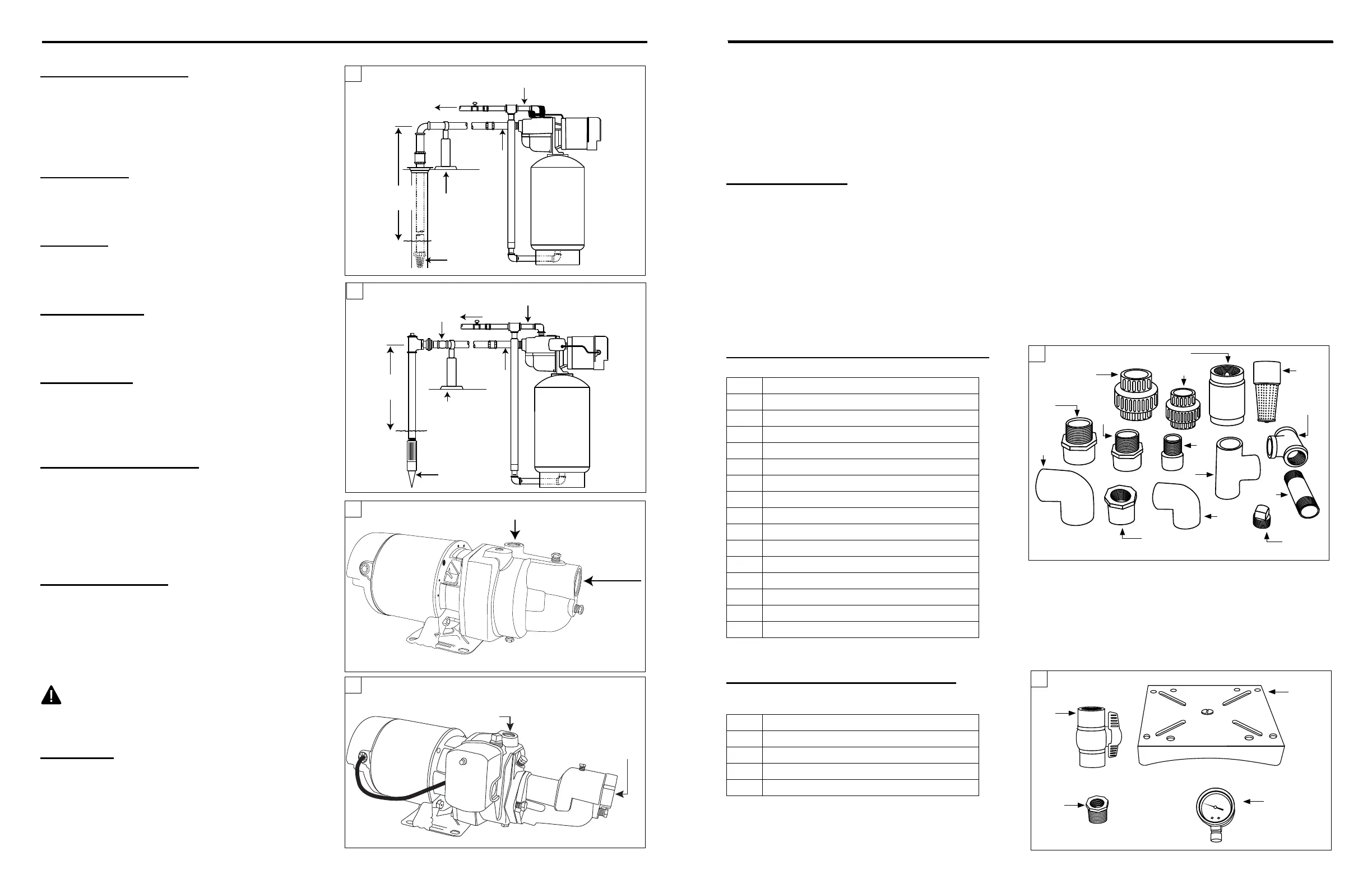

PARTS YOU MAY NEED FOR ASSEMBLY

(not included) (Fig. 1)

Item Description

1 1-1/4 In. union

2 1-1/4 in. adapter

3 1-1/4 in. elbow

4 3/4 in. union

5 1 in. adapter

6 1 in. x 3/4 in. reducer bushing

7 3/4 in. adapter

8 1 in. elbow

9 1-1/4 in. check valve

10 3/4 in. tee (plastic)

11 3/4 in. tee (steel)

12 3/4 in. x 3 in. nipple (steel)

13 3/4 in. plug (steel)

14 Foot valve

Electric cord strain relief

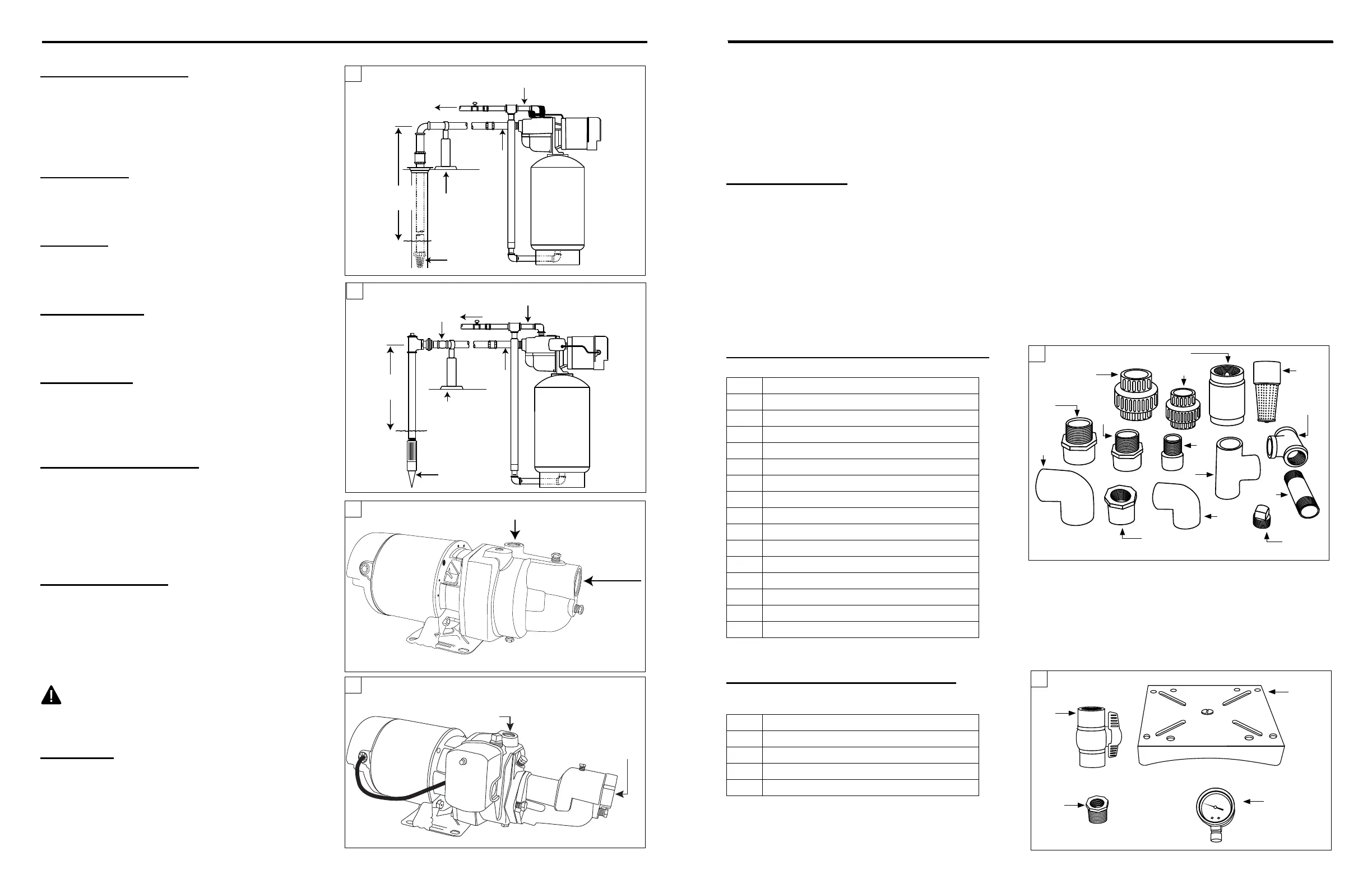

OPTIONAL PARTS FOR ASSEMBLY

(not included) (Fig 2)

Item Description

1 Ball Valve (plastic)

2 3/4 in. x 1/4 in. bushing (steel)

3 Pressure Gauge

4 Pump stand for tank

NOTE: For a successful installation, take time to study your application for the correct pipe size and

appropriate ttings. The illustrations in these instructions will assist you with required and optional

ttings. Sch. 40 PVC plastic pipe and ttings were used in these instructions.

Before beginning installation of product, make sure all parts are present. If any part is missing

or damaged, do not attempt to assemble the product. Contact customer service for replacement

parts.

Estimated Installation Time: 2 hours.

1

IL1383

l

ı

ı

ı

l

ı

ı

ı

ı

l

ı

ı

ı

l

ı

ı

ı

ı

l

ı

ı

ı

l

ı

ı

ı

l

ı

ı

ı

l

ı

ı

ı

ı

l

ı

ı

ı

l

ı

ı

ı

ı

l

ı

ı

ı

l

ı

ı

ı

ı

200

80

160

140

120

100

80

60

40

20

1

2

4

3

2

IL0068

3/4 or 1 in.

Discharge

1-1/4 in.

Suction

4

JHU10S, EK10S, CPH05S, JHU15S

ES05S, EK05S,

ES07S, EK07S

IL1472

Water Level

25 ft.

Max

Suction

Lift

3/4 or 1 in.

Discharge Pipe

1-1/4 in.

Suction

Pipe

Discharge

to Home

Pipe

Support

Drive Point

Check

Valve

2

IL1382

12

1

4

9

14

11

13

8

10

7

6

5

3

2

Loading...

Loading...