37

742.114 | 14.50

EN

10.3.6 Heat quantity

B

Calculates the acquired heat volume based on the following information:

• Supply temperature

• Return temperature

• Flow rate determined using the following methods:

– Calculated via pump speed

– Measured using a pulse water meter (terminal 5)

Notes

– Calculation based on the pump speed cannot be performed

when No system (system 0.1) has been selected.

– In drainback systems, the correct flow rate value can only be

read when the system is filled.

• Glycol proportion and accounting for the temperature dependent

thermophysical properties of the heat transfer fluid

Additional possibility: display of the amount of CO

2

saved by using the

system. The amount of CO

2

is calculated from the acquired heat volume.

To do this, the controller requires the conversion factor lbs

CO2

/kWh

therm

to be entered.

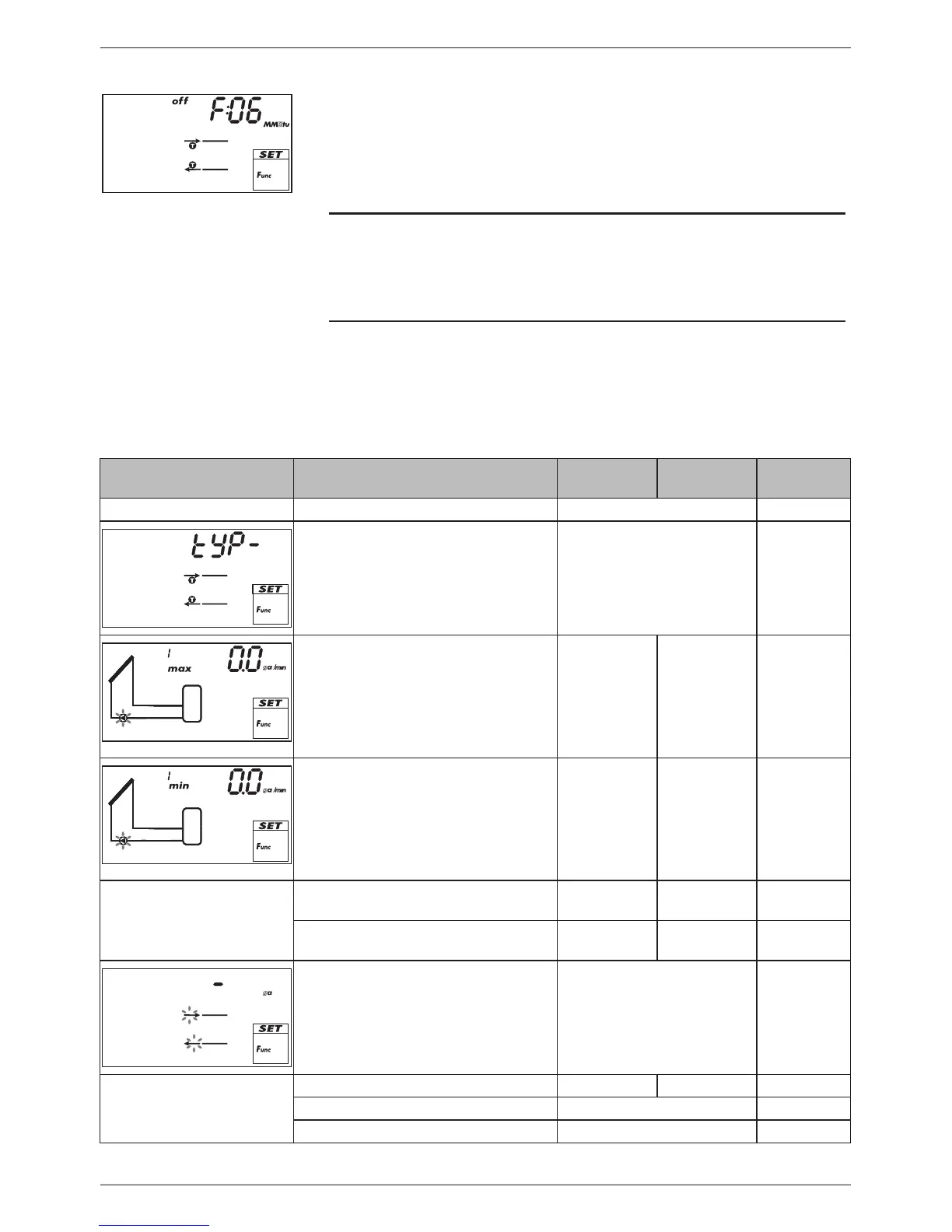

Display Characteristic min. max.

Factory

setting

Activation on, oFF

oFF

Type of flow rate acquisition tyP 1, tyP 2

1)

–

l

g

Type 1: flow rate value at max.

speed F

max.

(pump 1).

When the Fig. at the left is dis-

played (value flashes), then enter

the value read from the flow rate

display.

F

min.

999.9

gal/min

0.0 gal/min

l

g

Type 1: flow rate value at min.

speed F

min.

(pump 1).

When the Fig. at the left is dis-

played (value flashes), then enter

the value read from the flow rate

display.

0.0 gal/min F

max.

0.0 gal/min

Type 1: flow rate value at max.

speed F

max.

(pump 2)

2)

F

min.

999.9

gal/min

0.0 gal/min

Type 1: flow rate value at min.

speed F

min.

(pump 2)

2)

0.0 gal/min F

max.

0.0 gal/min

l

g

Type 2: flow rate of the pulse

water meter in litres/pulse; see

the pulse water meter data

sheet.

1.0 gal...10.0 gal,

1 l, 10 l, 25 l

– gal

(no flow

rate value

selected)

Glycol proportion 0% 60% 40%

Supply sensor input (warm) 1 ... 5 –

Return sensor input (cold) 1 ... 5 –

Loading...

Loading...