6947400000

18

MIG WELDING WITH GAS

Machine preparation

MIG welding can be performed in various ways,

depending on the specific needs of the operator. In

this case, proceed as follows to prepare the machine:

a) Connect the ground cable to the negative socket of

the generator.

b) Connect the bundle of cables to the front of the

generator, inserting the power cable into the positive

socket and the circular connector into the appropriate

socket.

c) Connect the bundle of cables to the wire feeder,

inserting the power cable on the Dinse socket (ref.L),

the gas pipe on the relative connection (ref.H), the 14-

pin connector on the appropriate socket (ref.G)

d) Connect the gas cylinder to the appropriate

connector using the supplied commissioning kit.

e) Place the reel of chosen wire on the appropriate

reel.

f) Open the wire drive compartment and pass the wire

through the drive rollers

WARNING

WELDING WIRE AND DRIVE PARTS FOR THE

FIRST 4 SECONDS ARE AT WELDING

VOLTAGE.

KEEP HANDS AWAY.

Insert the wire into the wire feeder making it

adhere to the groove of the roll (ATTENTION: the

roll has two grooves because by turning it it is

possible to use it for another diameter of wire. See

Rolls Specifications paragraph). When changing

the section of the wire it is necessary to change:

roller and current holder tube (it is the end part of

the torch from which the wire can be seen

emerging).

Unscrew the external termination of the torch

(nozzle) and the current tube to facilitate the

passage of the wire. Unwind the torch lead so that

the lead has as few bends as possible. Insert the

plug into a suitable socket (see connection

chapter).

g) Insert the power plug of the generator into a

socket suitable for current regulations.

h) Turn on the machine by activating the switch

located on the rear panel.

i) Connect the torch to the wire feeder, inserting the

Euro coupling on the front connector.

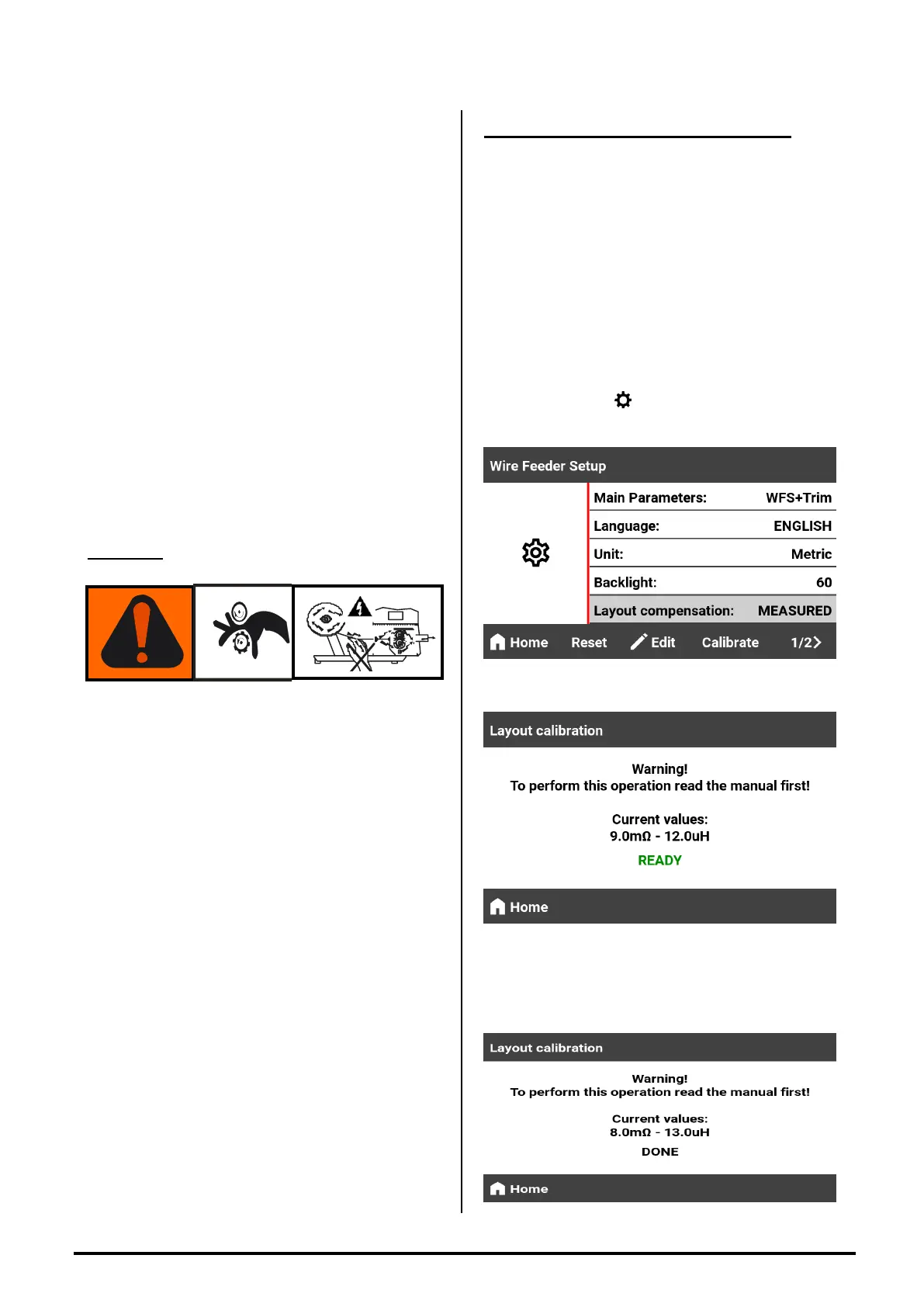

LAYOUT COMPENSATION

ATTENTION : Before starting to weld it is

advisable to carry out the LAYOUT

COMPENSATION to obtain a better welding

performance.

This operation must be done every time

the torch is replaced or the length of the

interconnecting cable or earth cable is

changed.

1) Connect the ground cable to the piece ;

2) Remove the gas nozzle from the torch;

3) Push the button Fig.1 rif.6 to access the

Wire Feeder Settings screen.

4) Push the button CALIBRATE

4) Rest the contact tip on the piece to be welded

and press the torch trigger;

5) After a few seconds if the measurement has

been done correctly the display will show this :

Loading...

Loading...