Classic Series www.stenner.com

26

TROUBLESHOOTING – PUMP TUBE

NOTICE: A leaking pump tube damages the metering pump. Inspect pump frequently

for leakage and wear. Refer to Tube Replacement section for additional safety

precautions and instructions.

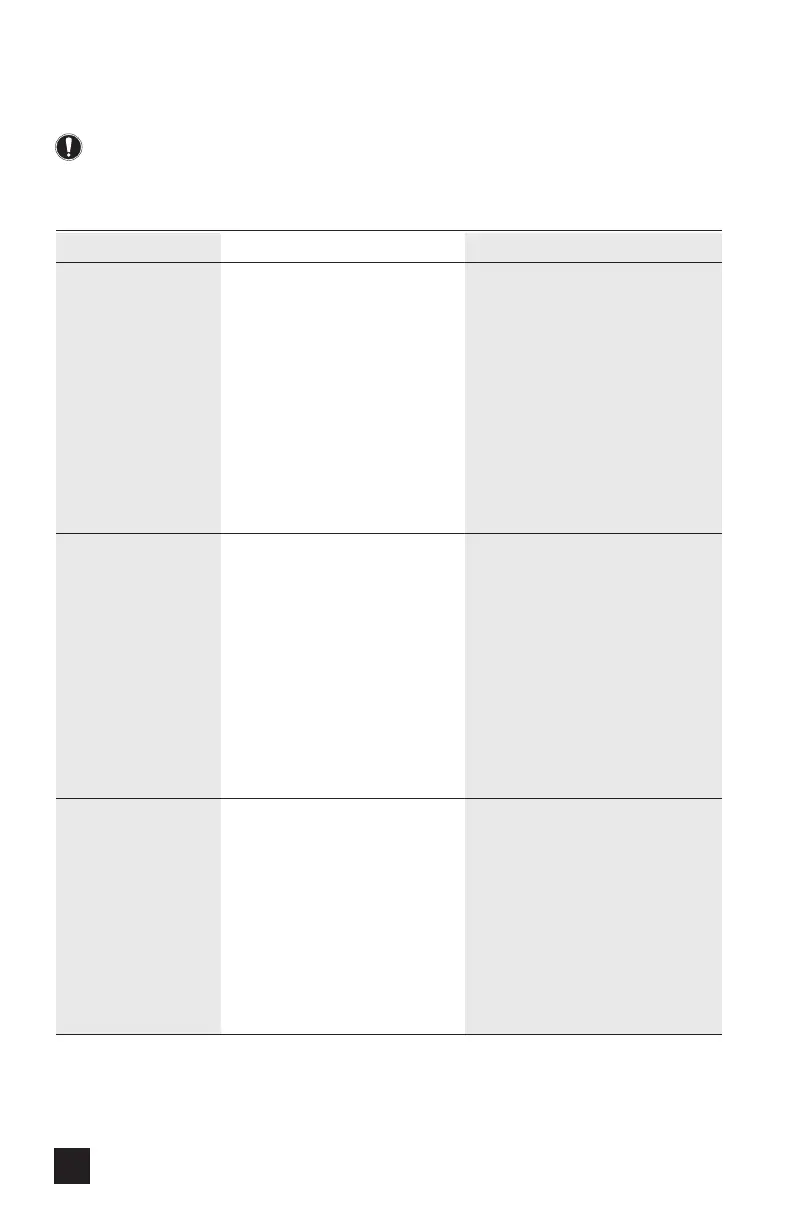

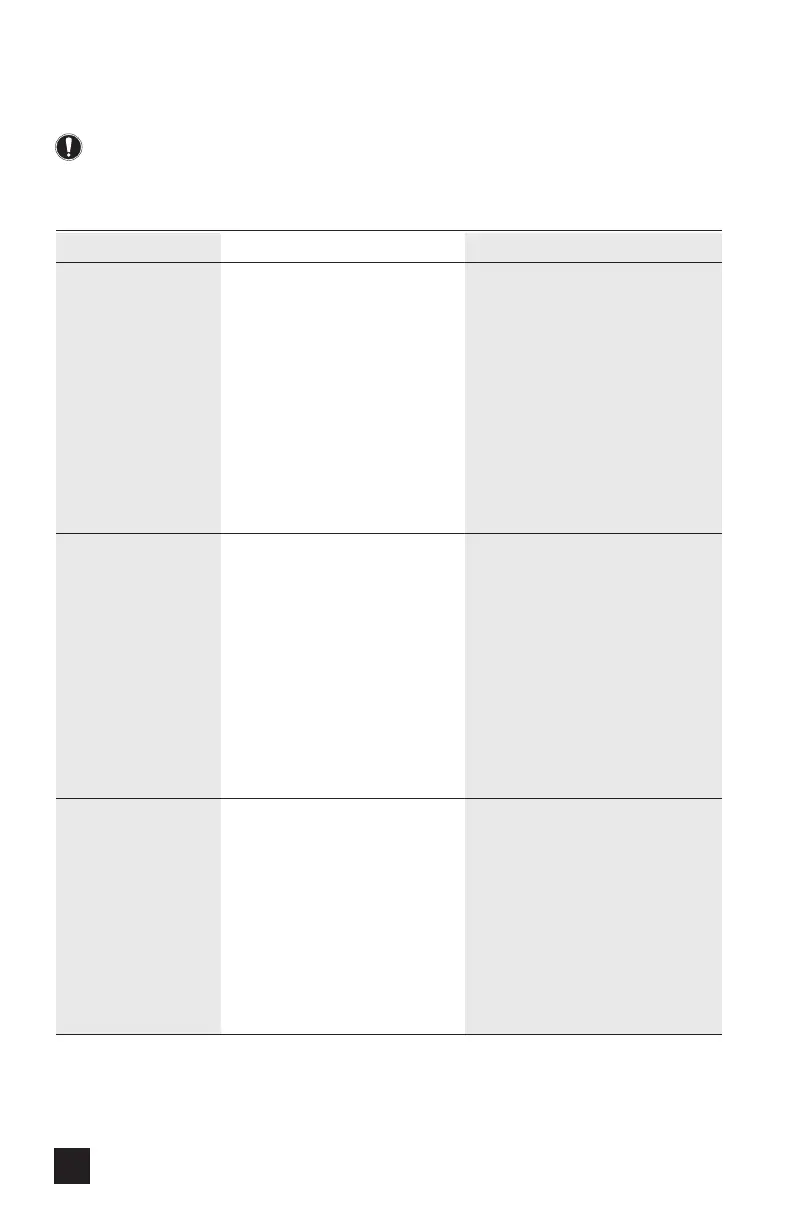

PROBLEM POSSIBLE CAUSE SOLUTION

Tube leaking Pump tube ruptured Identify and correct cause,

clean components of chemical &

replace tube according to instructions

Calcium or mineral deposits Clean injection fitting; replace tube and

duckbill according to instructions

Excessive back pressure Verify system pressure against tube psi,

replace tube if needed

Tube is twisted Replace tube according to instructions,

hold tube fitting while tightening

connecting nut to prevent twisting

Tube not centered Clean components of chemical,

replace tube according to instructions &

confirm tube is centered

Tube life is shortened Chemical attack Check chemical compatibility

Mineral deposits at injection point Remove deposits, replace pump tube

and duckbill according to instructions

Sediment blockage at check valve Clean injection fitting, ensure suction

line is 3" above tank bottom. Use

suction line strainer.

Degraded check valve duckbill Replace duckbill at every tube change

Duckbill in wrong orientation Reverse duckbill orientation

Seized rollers caused abrasion on tube Clean roller assembly or replace,

do not lubricate

Exposure to heat or sun DO NOT store tubes in high temperatures

or in direct sunlight

Tube connection is leaking Ferrules installed incorrectly, Replace ferrule, beveled end should face

missing or damaged the tube fitting

Crushed ferrule Replace ferrule

3/8" nut loose Secure adapter and tighten 3/8" nut

as needed

Missing ferrule in 3/8" adapter Replace with new adapter fitting or

insert new ferrule into adapter

Sleeve and/or plastic gripper inside Replace if damaged or missing/

3/8" connecting nut is missing Reorient if incorrectly assembled;

damaged, or incorrectly assembled gripper beveled end faces nut;

sleeve wider end faces gripper

Loading...

Loading...