Quick Start of T6 AC Servo

Performance adjustment—Tuning the inertia ratio(Pr0.04)

It is very important to find the ratio of inertia for one axis, in order to make best performance before

setting other parameter (for example, setting PID of position loop or velocity loop).

Connect motor with load if you need to test one axis.

Make sure the axis can be moved in safe distance, any interference should be avoided to ensure

safety and accuracy of testing.

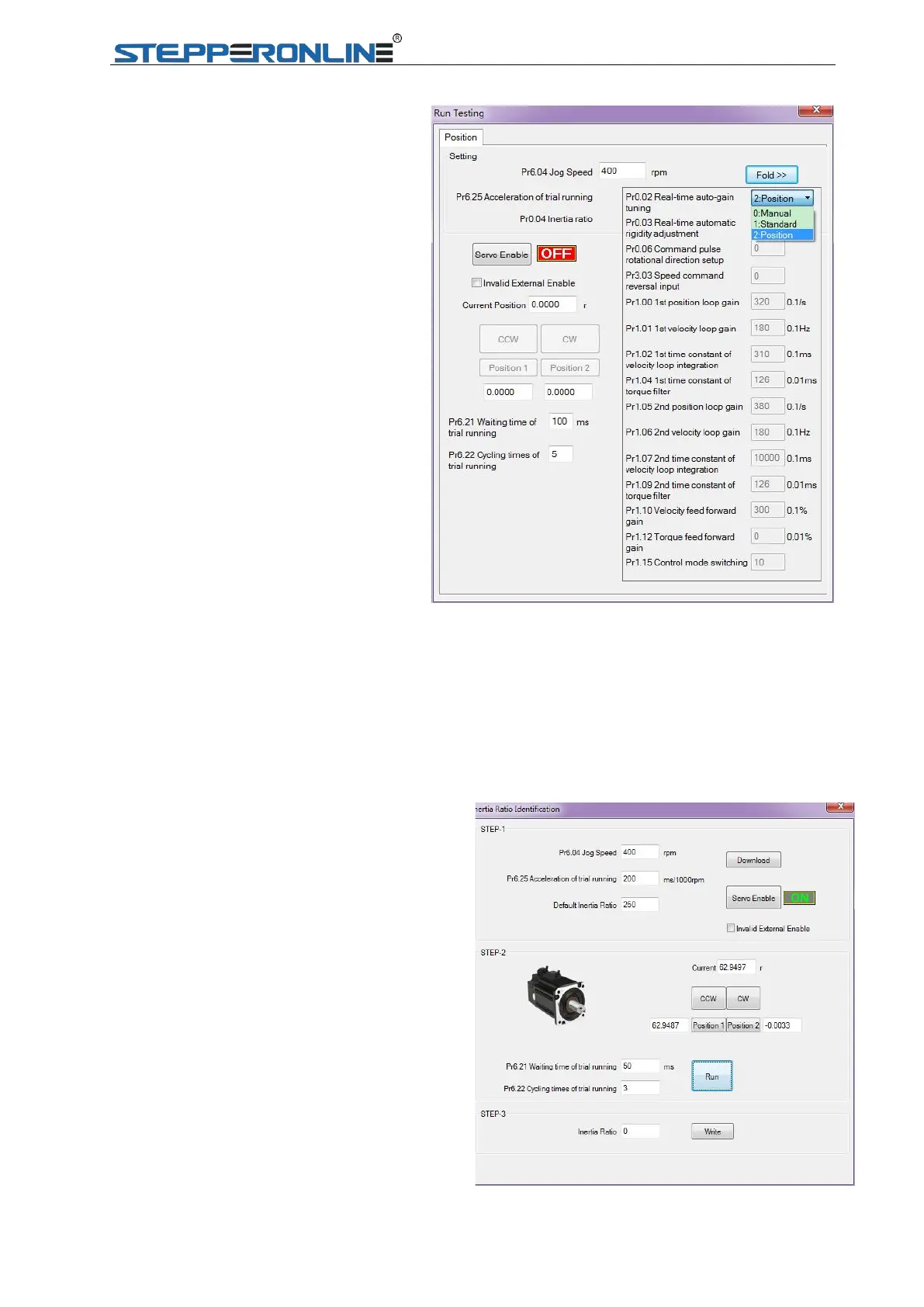

Inertia ratio identification

Pre-conditions:

1. Servo disable.

2. Positive limit and negative limit invalid

Steps:

1 Set the Jog speed Pr6.04, and the setting should not

be too large(300~1000rpm is recommend)

Set the Acc Pr6.25 (50~100 ms/1000rpm is recommend)

Set the Default Inertia Ratio.

Download these settings, then Servo Enable.

2. Click “CCW” to make motor run to CCW direction,

click “Position 1” to save the position limit 1

Click “CW” to make motor run to CW direction,click

“Position 2” to save the position limit 2

Click “Run” to start Inertia ratio dentification.

3. After finishing,Click“Write”to save the Inertia ratio

identification result into NVM.

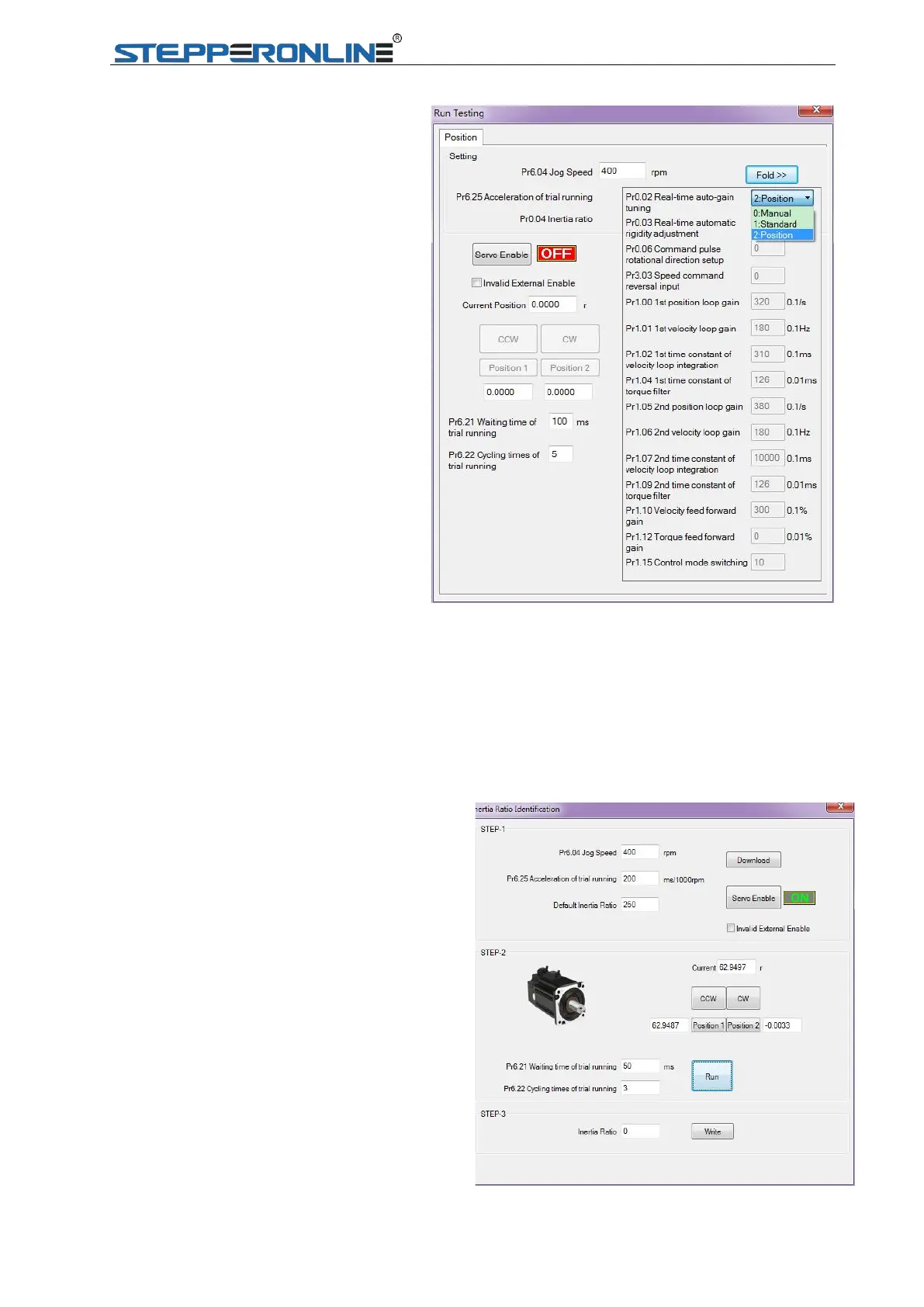

In Manual mode(Pr0.02=0), Kp, Ki and

other parameters can be set manually.

Pr003 is unavailable now .

About how to tune position loop, Ki can be

adjusted to a very small value in advance

and hold it constant, then enlarge the

value of Kp parameter slowly until system

oscillation occurs, at this moment enlarge

the value of Vi parameter slowly until

system oscillation occurs, at this moment

the basic adjustment of system is finished.

In Standard mode (Pr0.02=1), it is usually

for interpolation movement. It is

unavailable to modify the value of Pr1.00-

1.14, just change the value of Pr0.03 , then

all values of Pr1.00-1.14 will be changed at

the same time .

In Positioning mode(Pr0.02=2), it is

usually for point to point movement. It is

unavailable to modify the value of Pr1.00-

1.14, just change the value of Pr0.03, then

all values of Pr1.00-1.14 will be changed at

the same time.

Loading...

Loading...