TS 410, TS 420

English

12

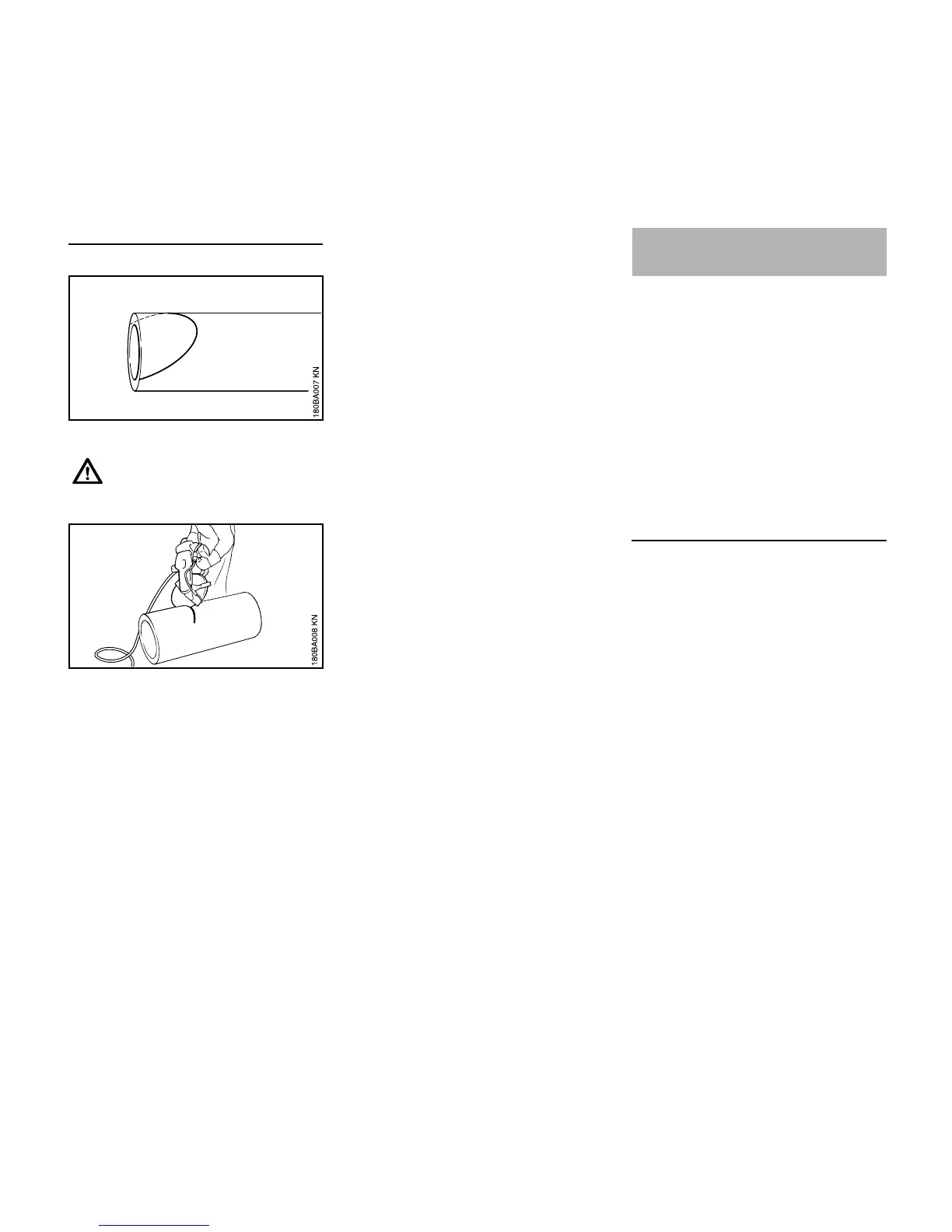

Shaping pipe

N Mark a cutting line

N Grind a guide groove along the

marked cutting line – do this by

starting at the apex and cut outward

on both sides

N Cut into pipes, round bodies, etc. in

the area at the ends of the cutting

line, so that the material does not

break away

N Make cuts deeper with even back

and forth motions – start at the apex

and cut outwards on both sides –

feed with full cutting depth along the

guide groove – for small corrections

of direction, do not tilt the cutting

wheel, but always position it anew

instead – if necessary, leave small

ridges that hold the part that is to be

separated in position. Break these

ridges later

Cutting wheels are exposed to

extremely high loads especially during

freehand cutting.

The cutting wheels, which have been

developed by STIHL in cooperation with

renowned manufacturers of abrasive

wheels, are of high quality and tailored

precisely to the respective intended use

as well as the engine performance of the

cut-off machine.

They are of consistently outstanding

quality.

Transport and storage

– Do not expose cutting wheels to

direct sunshine or other thermal

stresses during transport and

storage

– Avoid jolting and impacts

– Stack cutting wheels flat on a level

surface in the original packaging in

a dry place where the temperature

is as constant as possible

– Do not store cutting wheels in the

vicinity of aggressive fluids

– Store cutting wheels in a frost-free

place

Manual cutting along this line

requires particular caution and

precision.

Cutting wheels

Loading...

Loading...