•

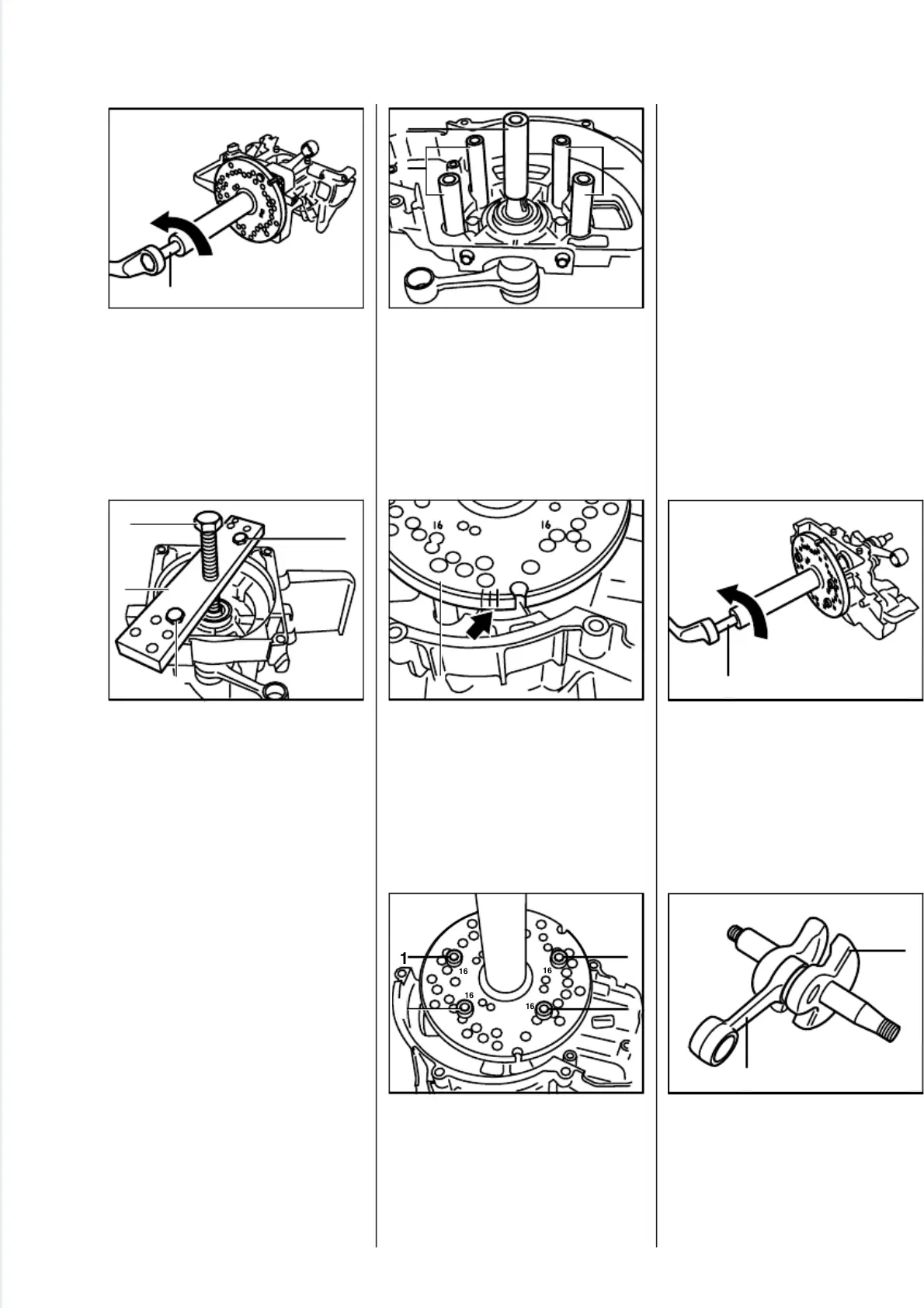

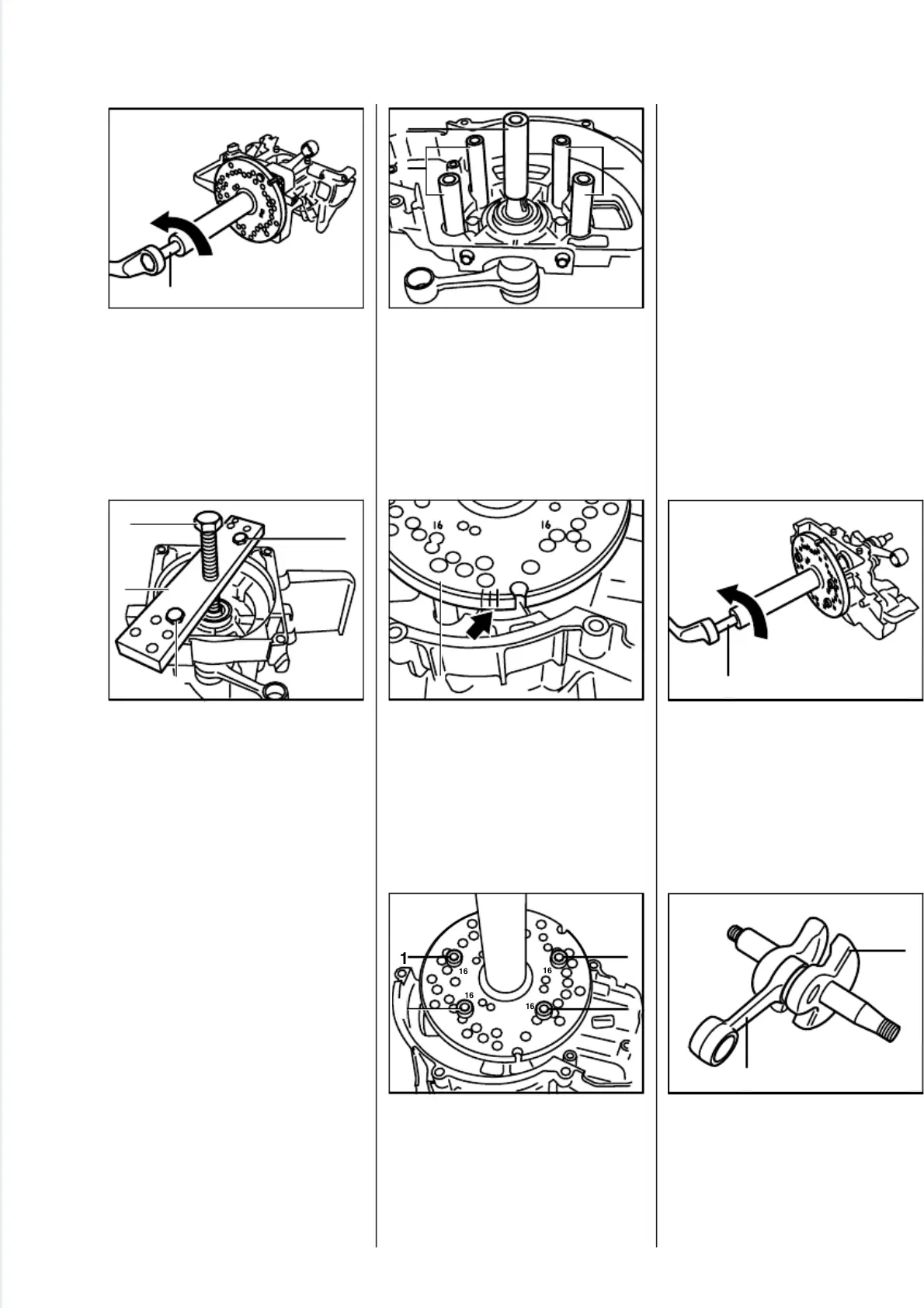

Rotate spindle (1) counterclock-

wise until the crankshaft comes

out of the ball bearing. The two

halves of the crankcase are

separated in this process.

•

Puller (1) 4119 890 4600 can be

used in place of the ZS installing

tool. It is mounted to the clutch

side of the crankcase wit M6x20

screws (2).

•

Turn thrust bolt (3) clockwise

until the crankshaft is released

from the ball bearing.

FS 120...350, FR 350

- Back off spindle (left-hand thre-

ad) of ZS installing tool

5910 890 2220 a little.

•

Place extension (1) 4116 894

1000 on crankshat stub and

sleeve (2) 1123 851 8300 on

bores at starter side of crank-

case.

•

Hold ZS installing tool (1)

5910 890 2220 against starter

side of crankcase so that the

notch marked "16" is at the

bottom.

•

Insert screws (1) 9022 341 1190

(from ZS installing tool kit) in

holes marked "16", fit washers at

other side and screw on nuts.

FS 400/450, FR 450

- Hold ZS installing tool against

starter side of crankcase so that

the notch marked "17" is at the

bottom.

- Insert M5x60 screws in holes

marked "18", fit washers at other

side and screw on nuts.

All models

•

Rotate spindle (1) counterclock-

wise until the crankshaft comes

out of the ball bearing.

•

The crankshaft (1), connecting

rod (2) and needle bearing form

an inseparable unit. It must

always be replaced as a com-

plete unit.

2

5

0

R

A

0

6

1

1

V

A

2

5

0

R

A

0

6

5

1

3

2

2

V

A

2

5

0

R

A

0

5

8

2

1

2

V

A

16

2

5

0

R

A

0

5

9

1

V

A

2

5

0

R

A

0

6

0

1

16

16

16

16

1

1

1

V

A

2

5

0

R

A

0

6

4

1

V

A

2

5

0

R

A

0

6

6

2

1

V

A

FS 120, 200, 300, 350, 400, 450, FR 350, 450 19

Loading...

Loading...