•

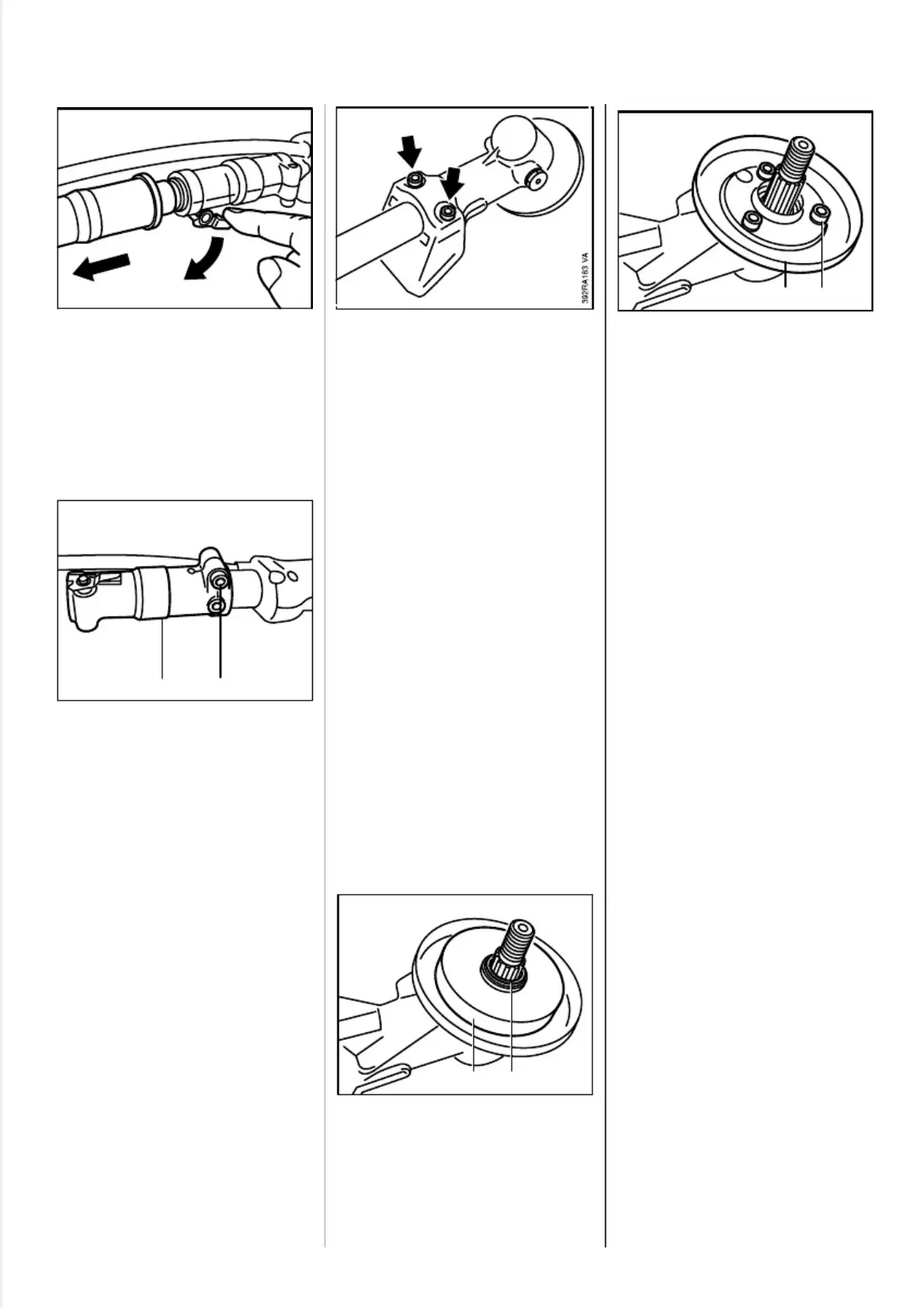

Press down the lever.

•

Pull out the flexible shaft.

•

Release the clamp screw (1).

•

Pull off the housing (2).

- Service the housing - see

"Standard Repairs, Trouble-

shooting" handbook.

Reassemble in the reverse

sequence.

- Degrease clamp mounting area.

- Tighten down clamp screw to

4.5 Nm (3.3 lbf.ft).

Illustration shows FS 120/200

gearhead.

- Remove deflector or stop, if fitted.

•

Release clamp screws.

- Pull gearhead off the drive tube.

FS 300...450

•

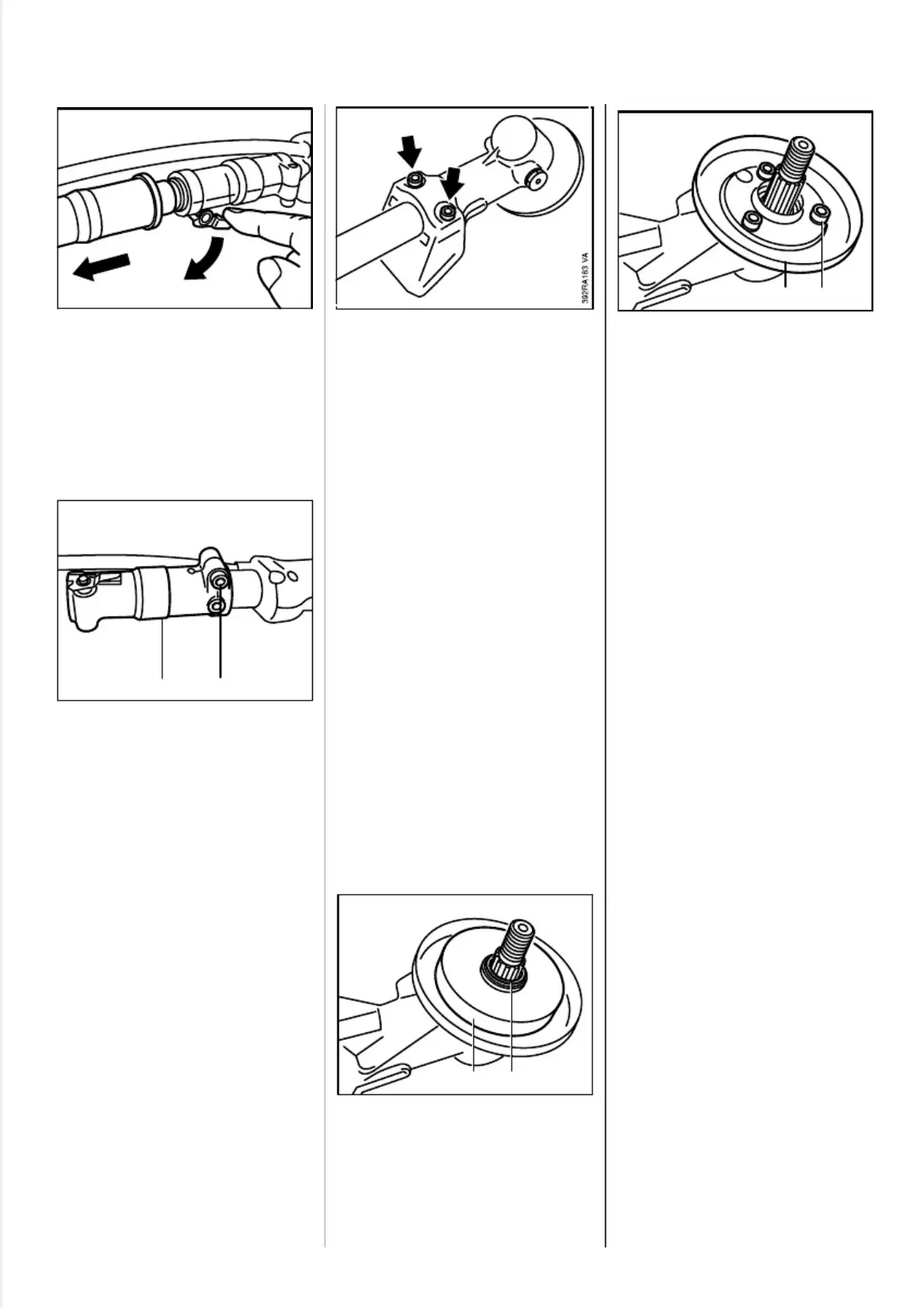

Remove retainer (1) - if fitted -

and thrust washer (2) from the

output shaft.

•

Take out screws (1).

•

Remove the guard ring (2).

- For other disassembly and

assembly procedures see

"Standard Repairs and Trouble-

shooting" handbook.

- On FS 300...450, tighten down

screws on guard ring to 5.0 Nm

(3.7 lbf.ft).

- Install a new retainer.

- Degrease clamp mounting area.

- Slide the gearhead onto the

drive tube - turn the output shaft

back and forth at the same time

so that the square end of the

drive shaft engages the square

socket in the drive pinion.

- Push the gearhead as far as

stop and line it up.

- On FS 120/200 and FR 350/450,

tighten down clamp screws to

8.5 Nm (6.3 lbf.ft).

- On FS 300...450, first tighten

clamp screws to 1.5 Nm (1.1

lbf.ft) and then finally tighten

them down to 7.5 Nm (5.5 lbf.ft).

- Refit the deflector or stop.

2

5

0

R

A

2

1

0

12

V

A

2

5

0

R

A

2

0

9

12

V

A

10.7 Housing (FR 350/450) 11. CUTTING TOOL DRIVE

11.1 Gearhead

2

5

0

R

A

2

4

3

V

A

2

5

0

R

A

2

4

4

2 1

V

A

56 FS 120, 200, 300, 350, 400, 450, FR 350, 450

Loading...

Loading...