FS 55, FS 55 C, FS 55 R, FS 55 RC

English

7

marks on the grip of the cap and on the

fuel tank opening lining up. Using the

grip, press the cap down firmly while

turning it clockwise as far as it will go

(approx. 1/4 turn).

Misaligned, damaged or broken cap

N If the cap does not drop fully into the

opening when the positioning marks

line up and/or if the cap does not

tighten properly when twisted, the

base of the cap may be prematurely

rotated (in relation to the top) to the

closed position. Such misalignment

can result from handling, cleaning

or an improper attempt at

tightening.

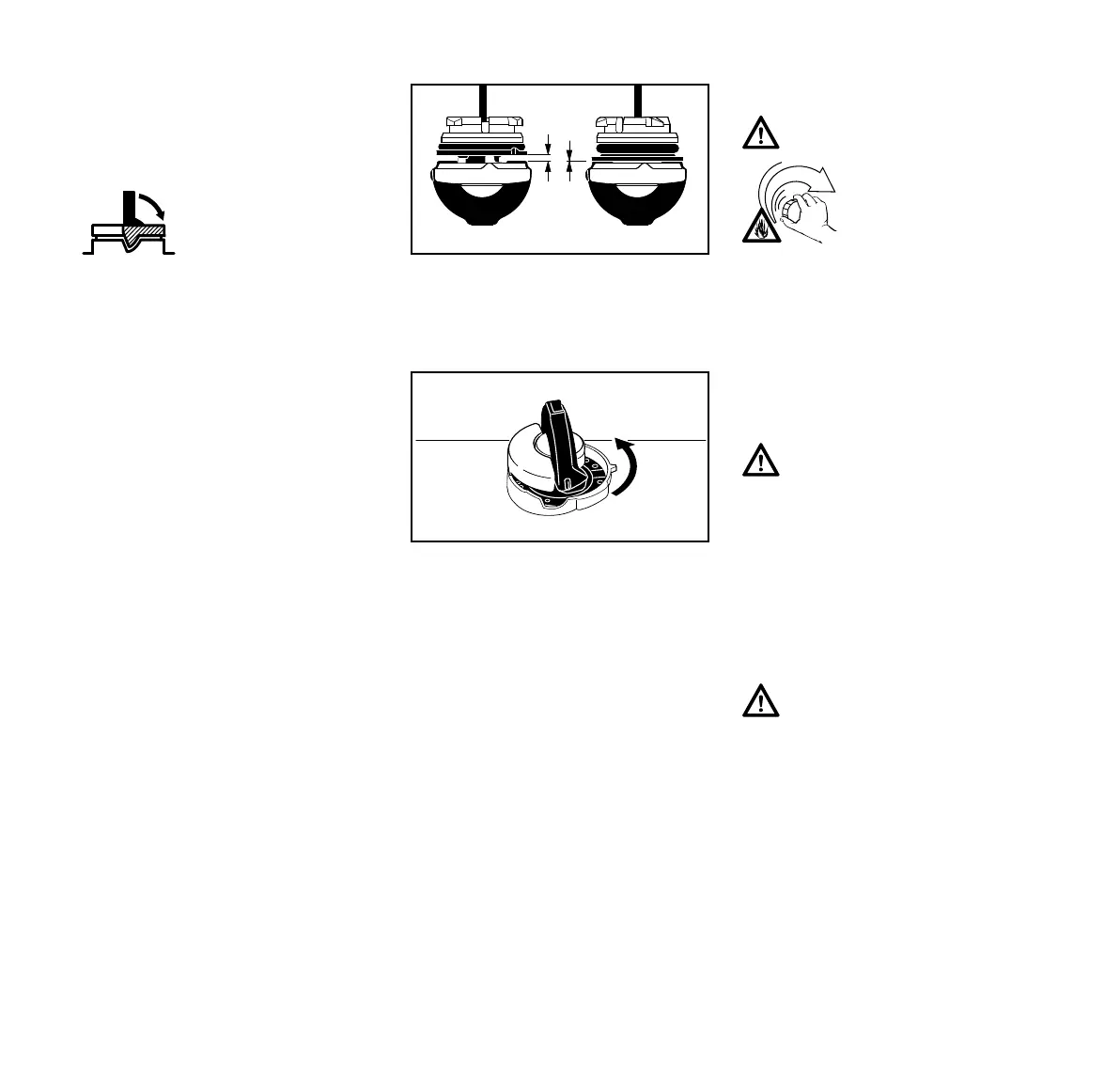

N To return the cap to the open

position for installation, turn the cap

(with the grip up) until it drops fully

into the tank opening. Next, twist the

cap counterclockwise as far as it will

go (approx. 1/4 turn) – this will twist

the base of the cap into the correct

position. Then, twist the cap

clockwise, closing it normally.

N If your cap still does not tighten

properly, it may be damaged or

broken; immediately stop use of the

unit and take it to your authorized

STIHL dealer for repair.

Screw Cap

See also the "Fueling" chapter in your

Instruction Manual for additional

information.

Before Starting

Fold the grip flush with

the top of the cap. Grip

the cap and check for

tightness. If the grip does

not lie completely flush

with the cap and the

detent on the grip does

not fit in the correspond-

ing recess in the filler

opening, or if the cap is

loose in the filler opening,

the cap is not properly

seated and tightened and

you must repeat the

above steps.

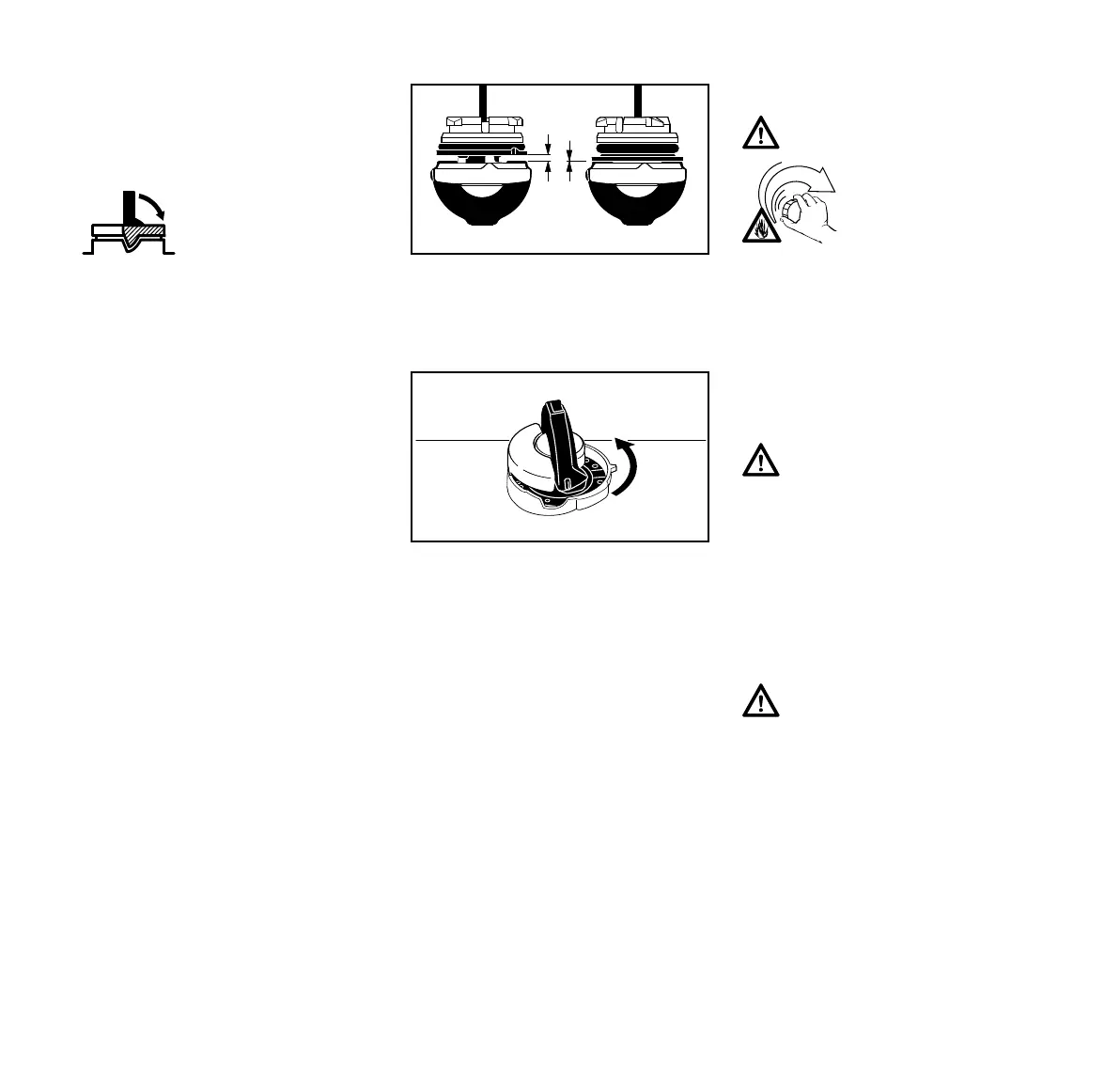

Left: Base of cap in closed posi-

tion (with open space)

Right: Base of cap correctly posi-

tioned for installation

Warning!

Unit vibrations can cause

an improperly tightened

fuel filler cap to loosen or

come off and spill quanti-

ties of fuel. In order to

reduce the risk of fuel

spillage and fire, tighten the fuel filler

cap by hand as securely as possible.

Warning!

Always check your power tool for proper

condition and operation before starting,

particularly the throttle trigger, throttle

trigger lockout, stop switch, cutting

attachment, deflector and harness. The

throttle trigger must move freely and

always spring back to the idle position.

Never attempt to modify the controls or

safety devices.

Warning!

Never operate your power tool if it is

damaged, improperly adjusted or main-

tained, or not completely or securely

assembled.

Loading...

Loading...