► If the chain sprocket cover is not flush with the

chainsaw: Twist the adjusting wheel and repo‐

sition the chain sprocket cover.

The teeth of the adjusting wheel engage with

the teeth of the tensioning gear.

► Rotate the wing nut clockwise until the chain

sprocket cover sits tightly at the chainsaw.

► Close the handle of the wing nut.

6.1.3 Removing the Guide Bar and Saw

Chain

► Shut off the engine and engage the chain

brake.

► Rotate the nut counterclockwise until the chain

sprocket cover can be removed.

► Remove the chain sprocket cover.

► Turn the tensioning screw counterclockwise as

far as it will go.

The saw chain is now slack.

► Remove the guide bar and saw chain.

6.1.4 Removing the Guide Bar and Saw

Chain (Quick Chain Tensioner)

► Shut off the engine and engage the chain

brake.

► Open the handle of the wing nut.

► Rotate the wing nut counterclockwise until the

chain sprocket cover can be removed.

► Remove the chain sprocket cover.

► Turn the tensioning gear clockwise as far as it

will go.

The saw chain is now slack.

► Remove the guide bar and saw chain.

► Remove the screw of the tensioning gear.

► Remove the tensioning gear.

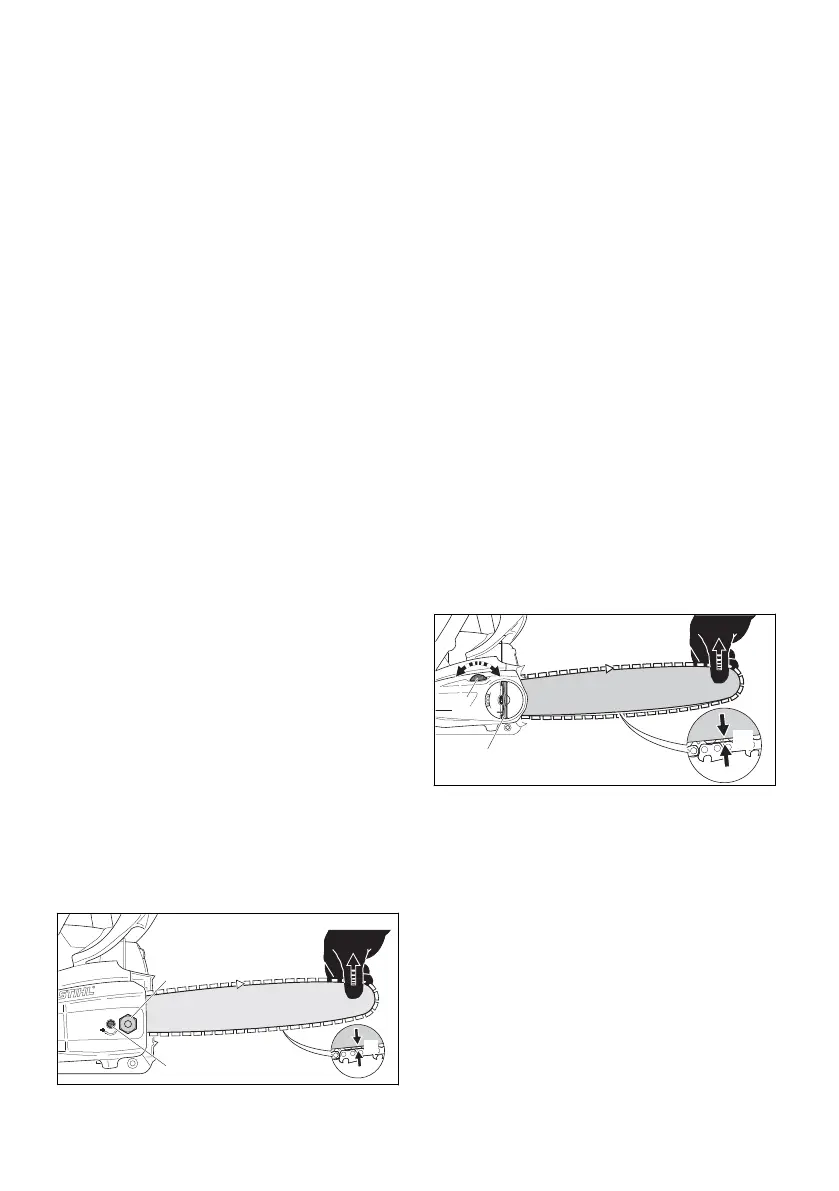

6.2 Tensioning the Chain

6.2.1 Tensioning the Saw Chain

The saw chain expands or contracts during cut‐

ting work. The saw chain tension changes as a

result. Check the saw chain tension regularly

during operation and readjust if necessary.

► Shut off the engine and engage the chain

brake.

► Loosen the nuts (1).

► Disengage the chain brake.

► Hold the guide bar nose up and turn the ten‐

sioning screw (2) clockwise or counterclock‐

wise until the following points apply:

–

The chain sag ‘a’ in the center of the guide

bar is 1 - 2 mm.

–

The saw chain can still be pulled easily

along the guide bar with two fingers.

► If a Carving guide bar is used: Turn the ten‐

sioning screw (2) clockwise until the drive links

on the underside of the bar are just half-visi‐

ble.

► Keep holding the guide bar nose up and screw

the nuts (1) tight.

► If the chain sag ‘a’ in the center of the guide

bar is not 1-2 mm: Readjust the saw chain ten‐

sion.

► If you are using a Carving bar and the drive

links on the underside of the bar are less than

half-visible: Readjust chain tension.

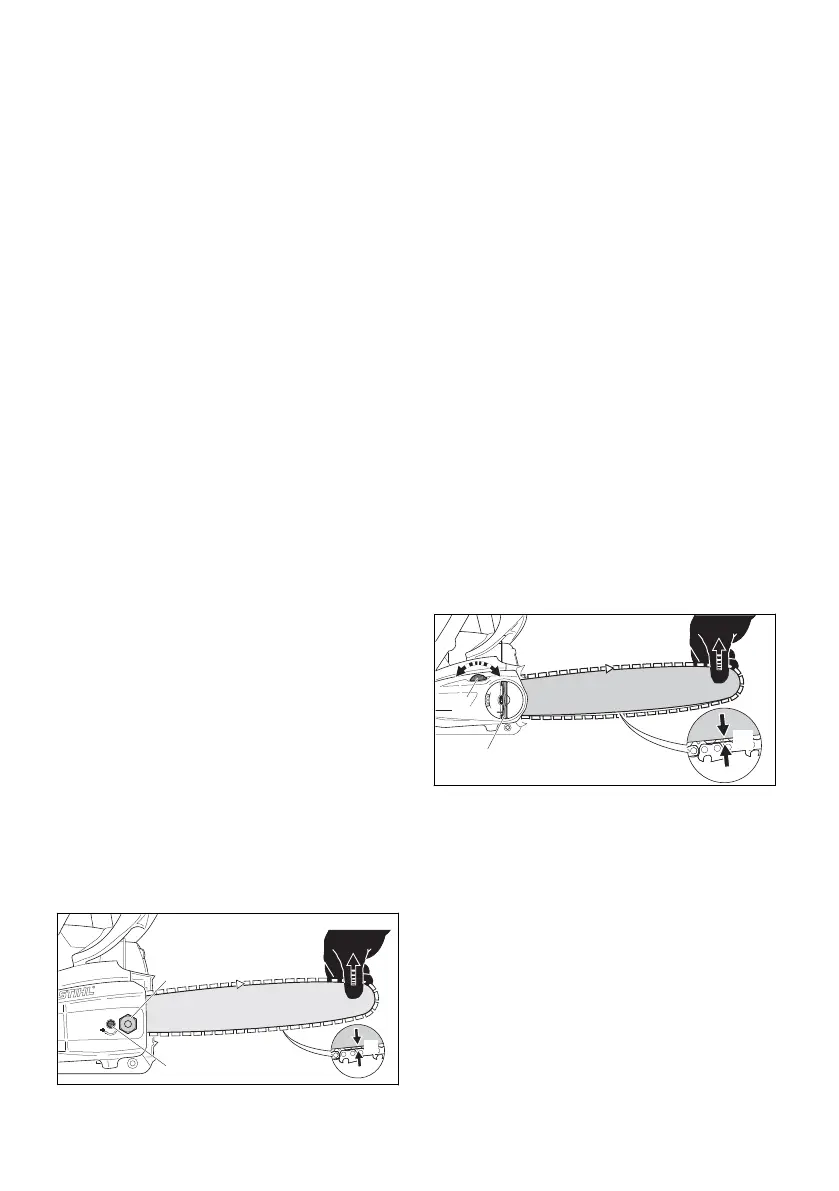

6.2.2 Tensioning the Saw Chain (Quick

Chain Tensioner)

The saw chain expands or contracts during cut‐

ting work. The saw chain tension changes as a

result. Check the saw chain tension regularly

during operation and readjust if necessary.

► Shut off the engine and engage the chain

brake.

► Open the handle of the wing nut (1).

► Back off the wing nut (1) 2 turns counterclock‐

wise.

You have loosened the wing nut (1).

► Disengage the chain brake.

► Hold the guide bar nose up and turn the

adjusting wheel (2) clockwise or counterclock‐

wise until the following points apply:

–

The chain sag ‘a’ in the center of the guide

bar is 1 - 2 mm.

–

The saw chain can still be pulled easily

along the guide bar with two fingers.

► If a Carving guide bar is used: Turn the ten‐

sioning screw (2) clockwise or counterclock‐

wise until the drive links on the underside of

the bar are just half-visible.

6 Assembling the Saw English

0458-200-0121-B 13

Loading...

Loading...