MS 210, MS 210 C, MS 230, MS 230 C, MS 250, MS 250 C

English

32

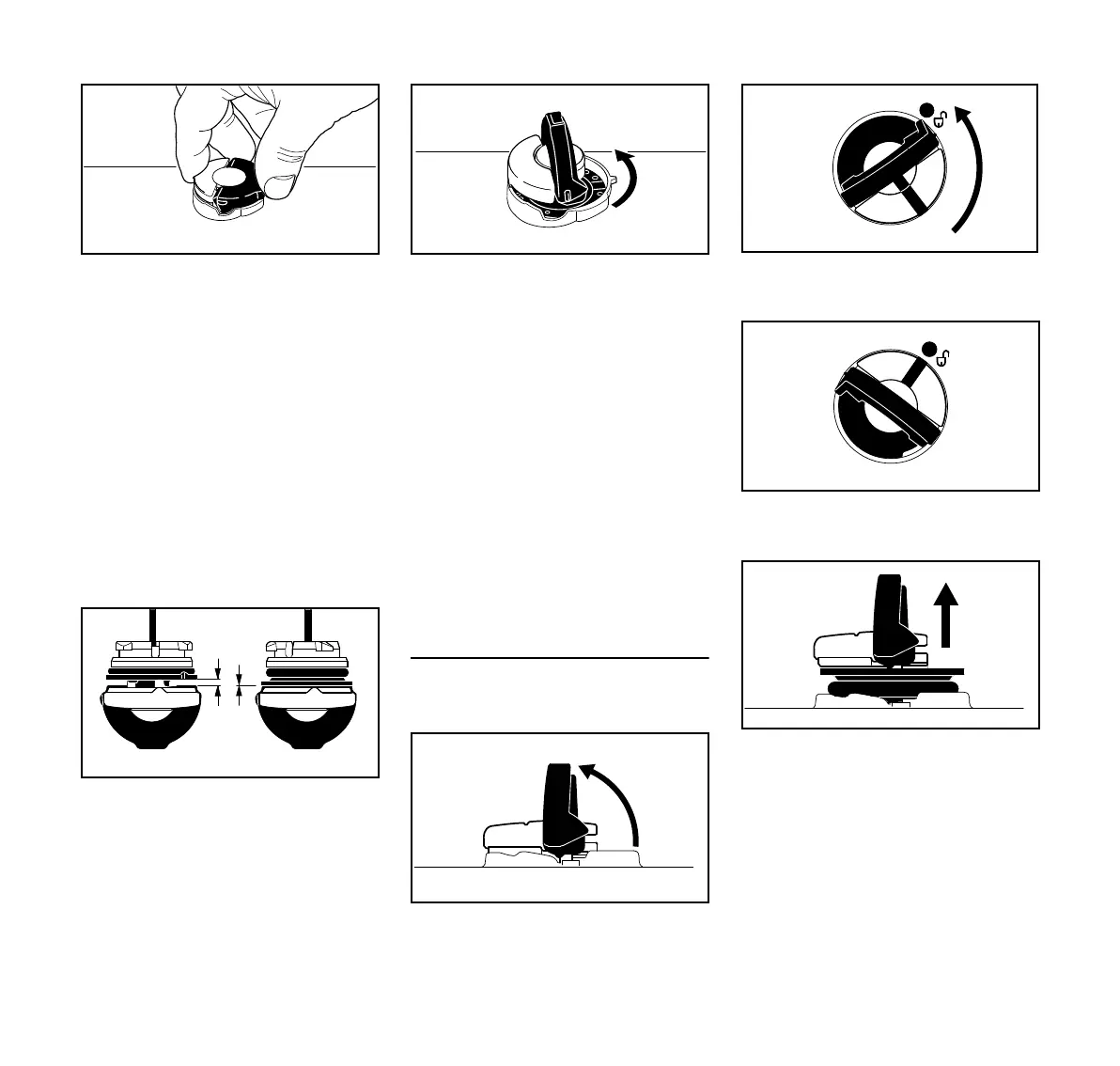

N Grip the cap and check for

tightness.

N If the cap can be moved, it is not

properly installed.

Misalignment of the cap parts

N If the cap does not drop fully into the

opening when the positioning marks

line up and/or if the cap does not

tighten properly when twisted, the

base of the cap may be rotated out

of position vis-à-vis the top.

N Such misalignment can result from

handling, cleaning or an improper

attempt at tightening.

N To correct a misalignment, turn the

cap (with the grip up) until it drops

fully into the tank opening.

N Twist the cap counterclockwise as

far as it will go (approx. 1/4 turn) –

this will twist the base of the cap into

the correct position.

N Twist the cap clockwise, closing it

normally – see the sections

"Closing" and "Checking for proper

closure."

N If your cap still does not tighten

properly, it may be damaged or

broken; immediately stop use of the

unit and take it to your authorized

STIHL dealer for repair.

Filler cap with markings and symbols

Opening

N Raise handle.

N Twist filler cap counterclockwise

(approx. 1/4 turn).

Markings on filler cap and housing must

align.

N Remove the filler cap.

Refueling

Take care not to spill fuel while fueling

and do not overfill the tank – leave

approx. 1/2" (13 mm) air space.

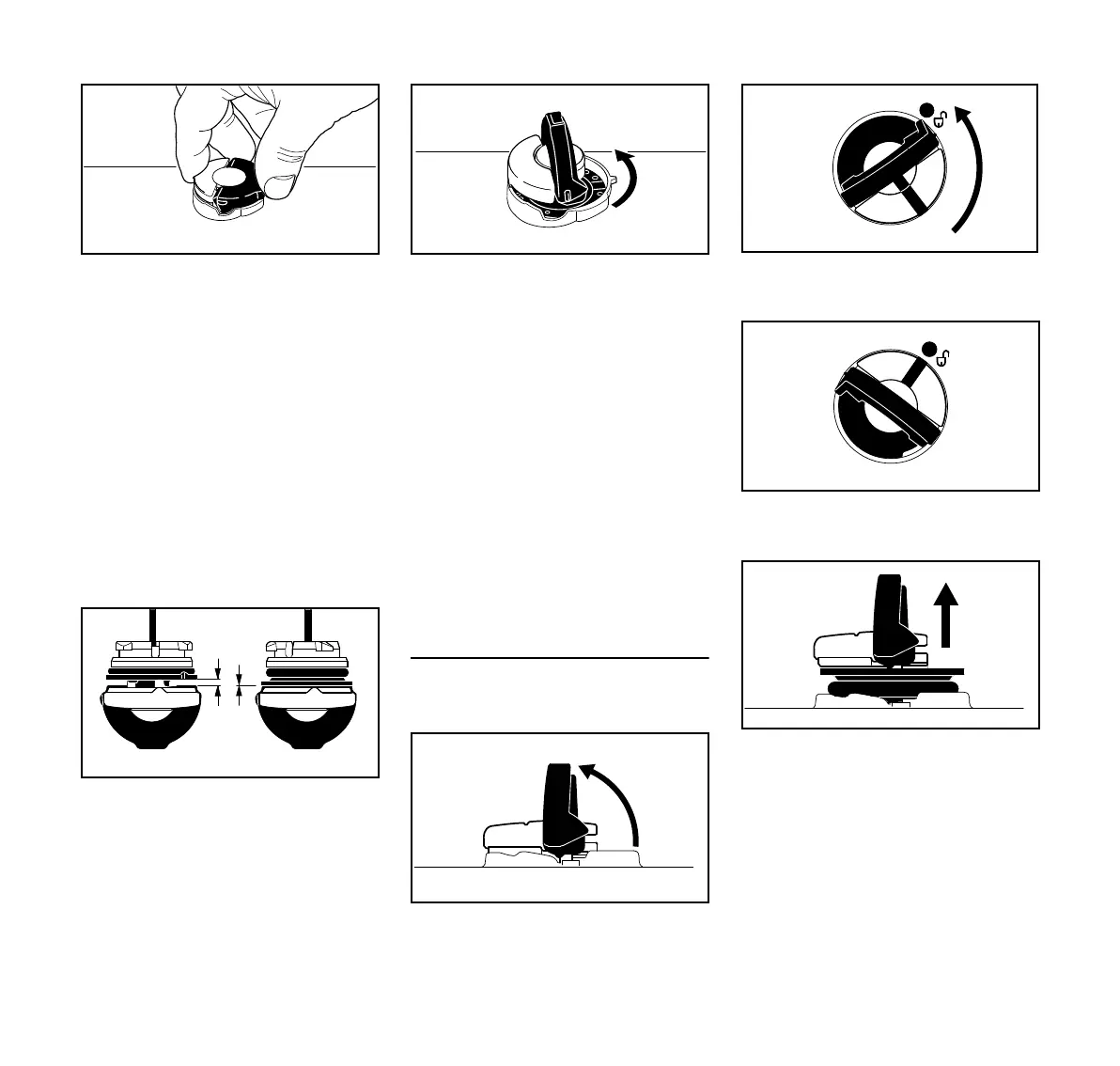

Left: Base of improperly aligned

cap (with open space)

Right: Base of cap correctly posi-

tioned for installation

Loading...

Loading...