MS 251 C-Q

English

35

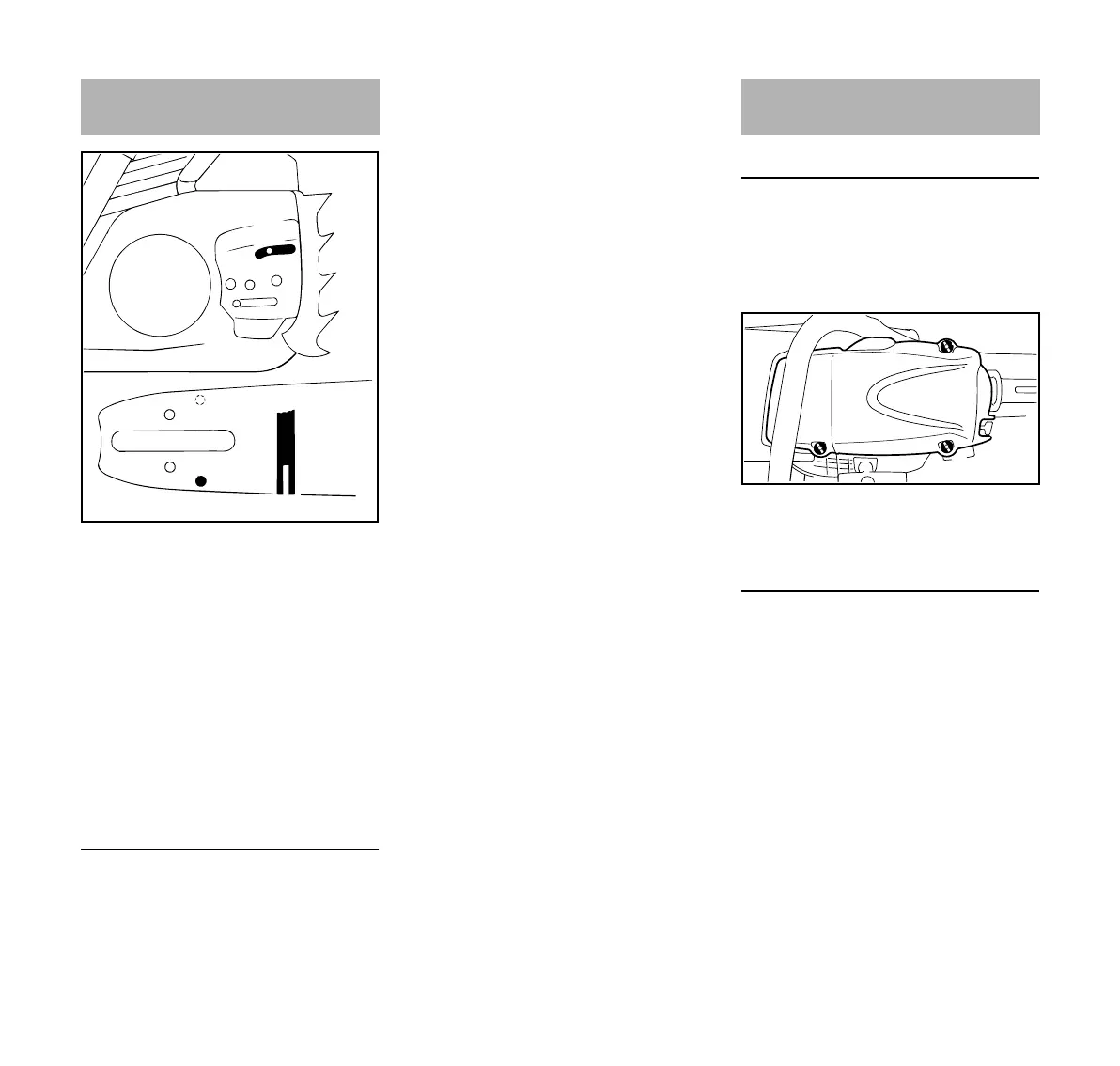

N Flip the bar – after each sharpening

and each time the chain is changed

– to avoid uneven wear, especially

at the sprocket nose and on the

bottom

N Periodically clean the oil inlet

hole (1), oil outlet channel (2) and

bar groove (3)

N Measure groove depth – using the

measuring tool on the file gauge

(special accessory) – in the area

with the greatest wear

If the groove is not at least this deep:

N Replace guide bar

Otherwise the drive links will grind

against the base of the groove – the

bottoms of the cutters and the tie straps

will not lie against the bar.

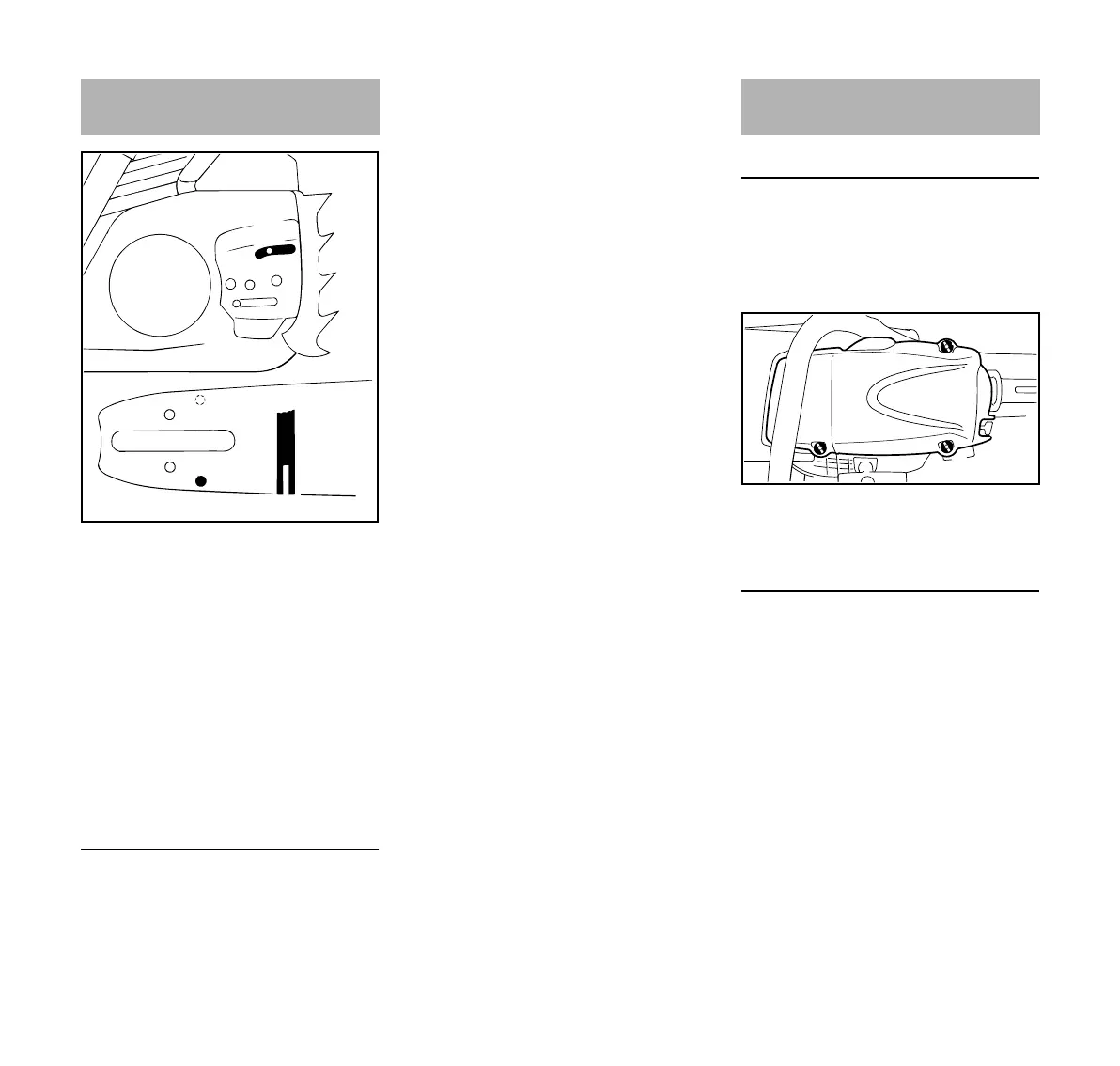

Remove shroud

N Move the Master Control Lever to

the stop position 0

N Push the front hand guard forwards

– the saw chain is blocked

N Loosen screws (1)

N Remove the shroud (2)

Refitting the shroud

N Refit the shroud and tighten the

screws

Taking Care of the Guide Bar

Chain type Chain pitch Minimum

groove depth

Picco 1/4“ P 4.0 mm

Rapid 1/4“ 4.0 mm

Picco 3/8“ P 5.0 mm

Rapid 3/8“; 0.325“ 6.0 mm

Rapid 0.404“ 7.0 mm

Shroud

Loading...

Loading...