MS 311, MS 391

English

35

When the specified files and/or

sharpening tools and the proper setting

are used, the specified values for angles

A and B will be attained automatically.

The angles must be identical for all

cutters in the saw chain. Varying angles:

Rough, uneven running of the saw

chain, increased wear – even to the

point of saw chain breakage.

Because these requirements can be met

only after sufficient, constant practice:

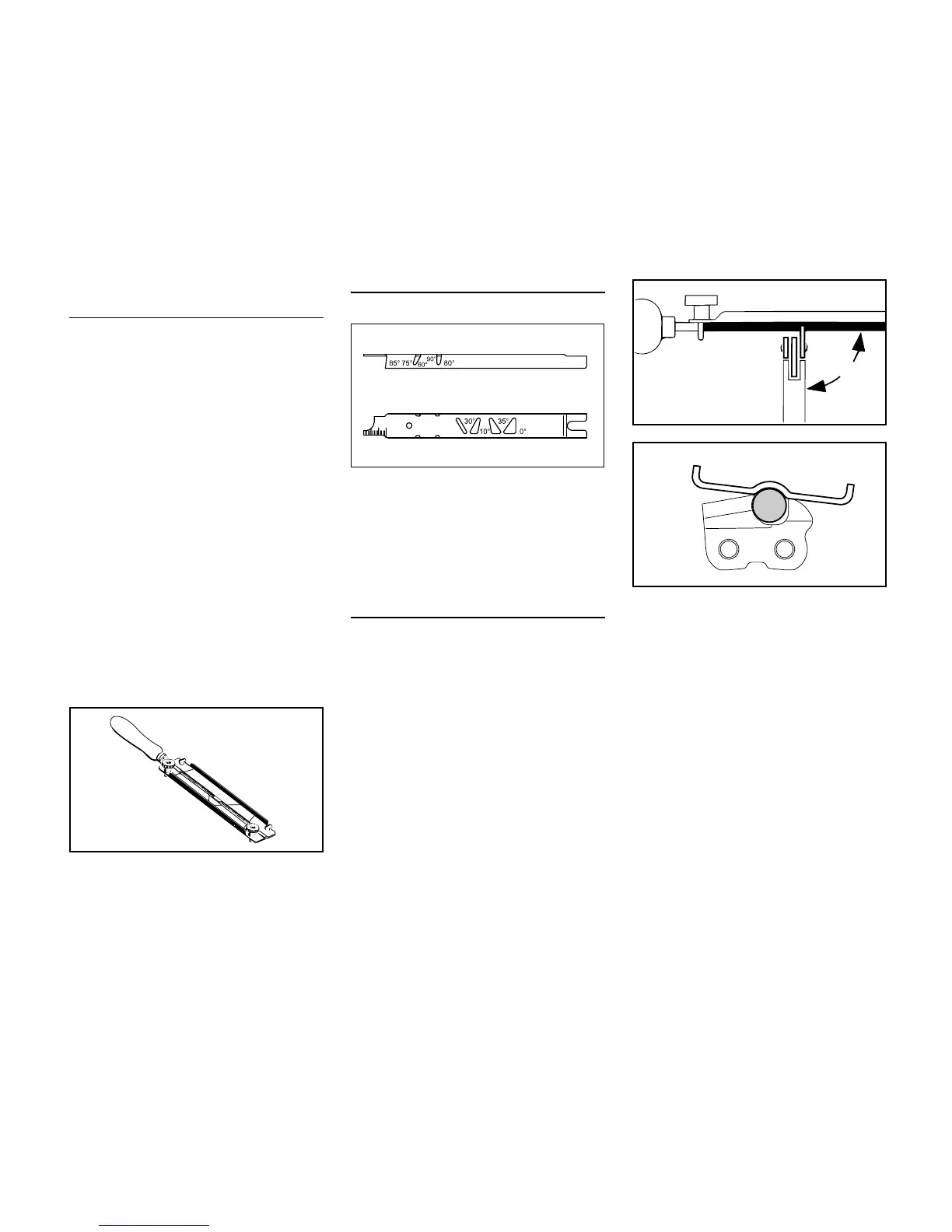

N Use a file holder

Always use a file holder (special

accessory, see table "Sharpening tools")

when sharpening saw chains by hand.

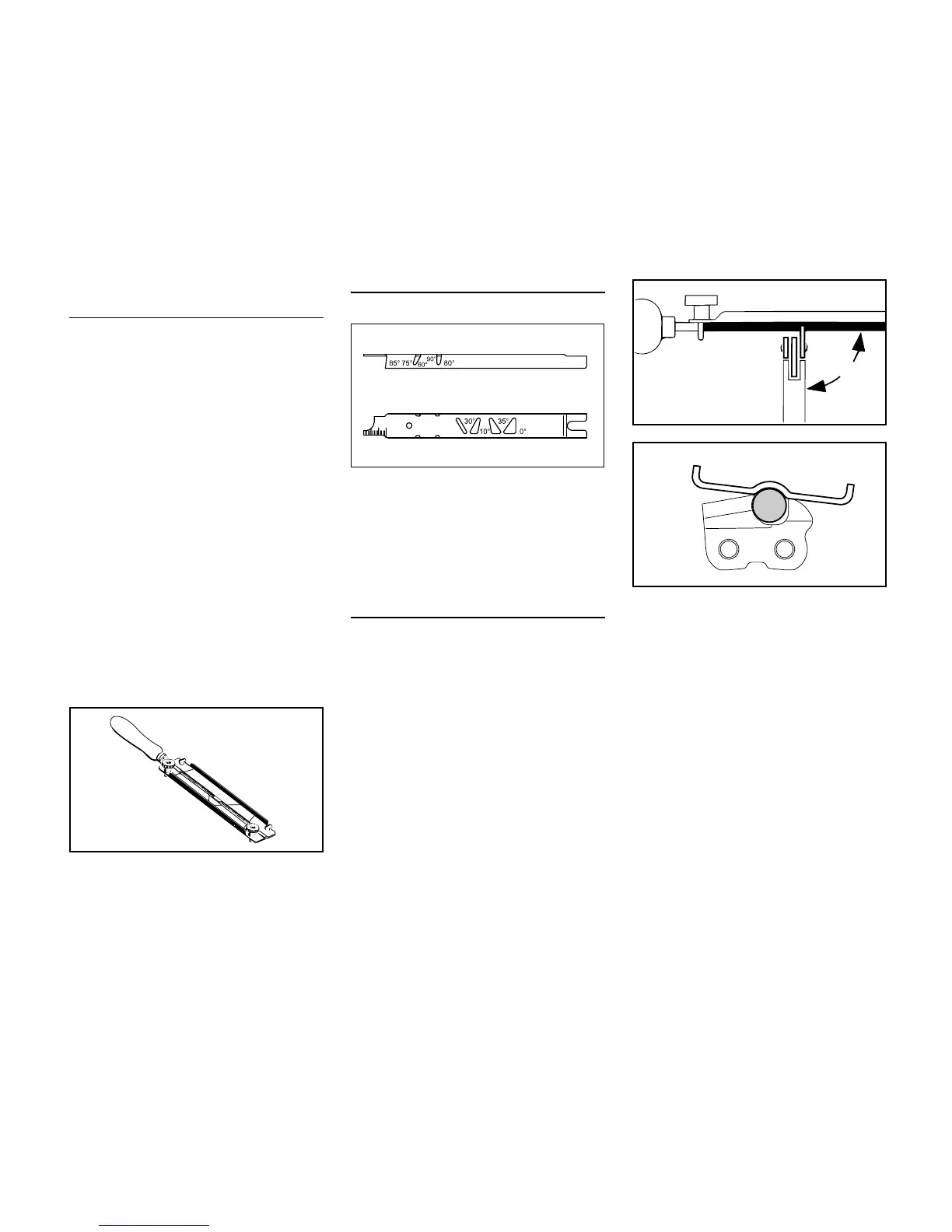

File holders have markings for the

sharpening angle.

To check the angles

STIHL filing gauge (special accessory,

see table "Sharpening tools") – a

universal tool for checking sharpening

and side plate angles, depth gauge

setting, and tooth length, as well as

cleaning grooves and oil inlet holes.

Proper sharpening

N Select sharpening tools in

accordance with chain pitch

N Clamp guide bar if necessary

N Block saw chain – push the hand

guard forward

N To advance the saw chain, pull the

hand guard toward the handlebar:

The chain brake is disengaged.

With the Quickstop Super chain

brake system, additionally press the

throttle trigger lockout

N Sharpen frequently, removing little

material – two or three strokes of the

file are usually sufficient for simple

resharpening

N Guide the file: horizontally (at a

right angle to the side surface of the

guide bar) in accordance with the

specified angle – according to the

markings on the file holder – rest the

file holder on the tooth head and the

depth gauge

N File only from the inside outward

N The file only sharpens on the

forward stroke – lift the file on the

backstroke

N Do not file tie straps and drive links

N Rotate the file a little periodically in

order to avoid uneven wear

N To remove file burr, use a piece of

hardwood

N Check angle with file gauge

All cutters must be equally long.

Chain Type Angle (°)

AB

Rapid Micro (RM) 30 75

Rapid Super (RS) 30 60

Picco Micro (PM) 30 75

Rapid Micro X (RMX, rip-

ping chain)

10 75

Picco Micro X (PMX, rip-

ping chain)

10 75

Tooth shapes

Micro = semi-chisel tooth

Super = chisel tooth

689BA025 KN

001BA203 KN

689BA018 KN

90°

689BA043 KN

Loading...

Loading...