2. Equipment

The STIHL TS 400 is equipped with the newly developed long-term air filter system with compensator, the

STIHL quickstart system with ElastoStart and decompression valve, the AV handle system, semi-automatic

V-belt tensioner, fuel tank with integrated expansion reservoir, electronic magneto-ignition system with

speed limitation, and a new, light aluminium guard.

1

2

3

338TI001 K

3. Technical description

Air filter system and compensator

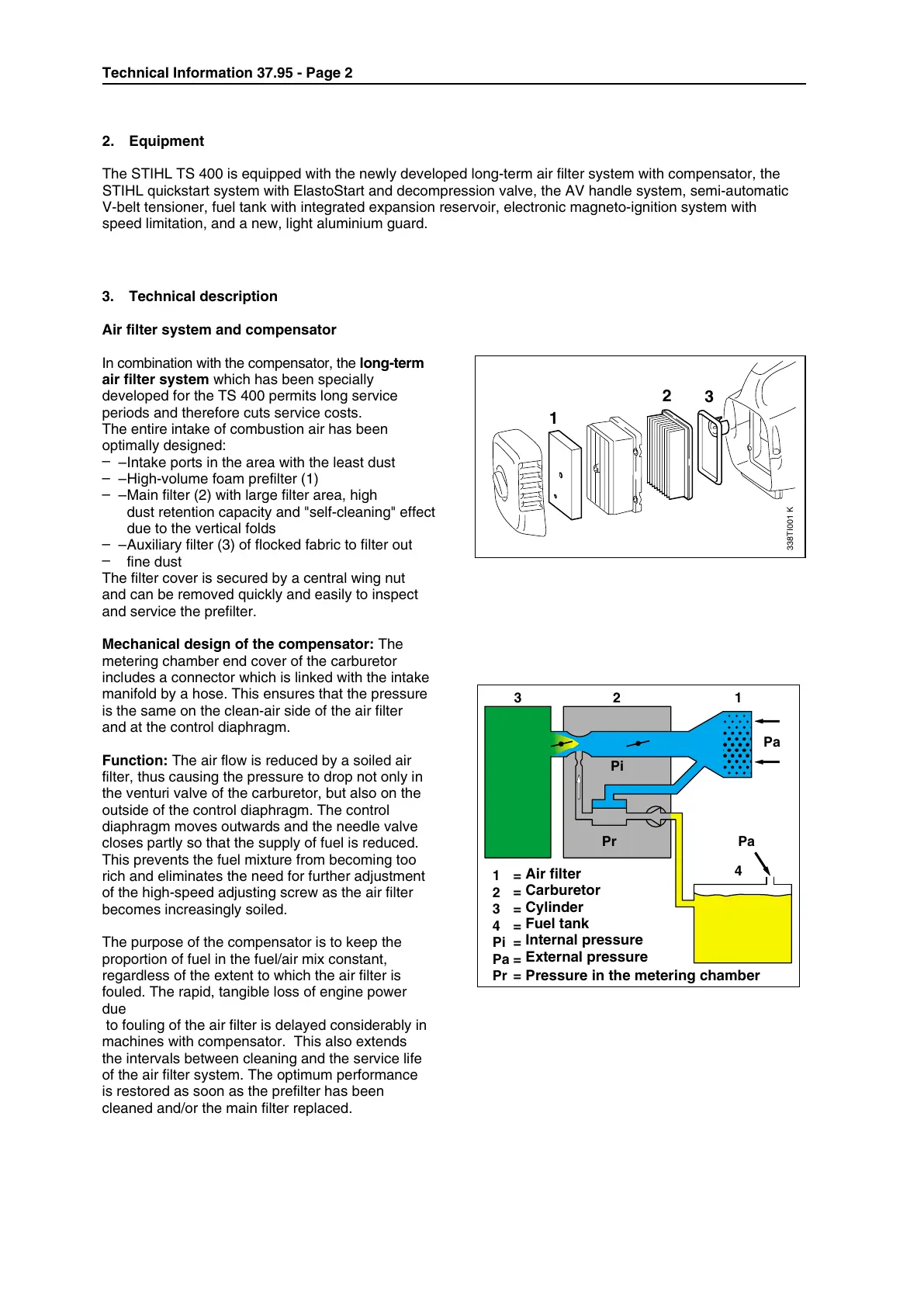

In combination with the compensator, the long-term

air filter system which has been specially

developed for the TS 400 permits long service

periods and therefore cuts service costs.

The entire intake of combustion air has been

optimally designed:

–

–Intake ports in the area with the least dust

–

–High-volume foam prefilter (1)

–

–Main filter (2) with large filter area, high

dust retention capacity and "self-cleaning" effect

due to the vertical folds

–

–Auxiliary filter (3) of flocked fabric to filter out

–

fine dust

The filter cover is secured by a central wing nut

and can be removed quickly and easily to inspect

and service the prefilter.

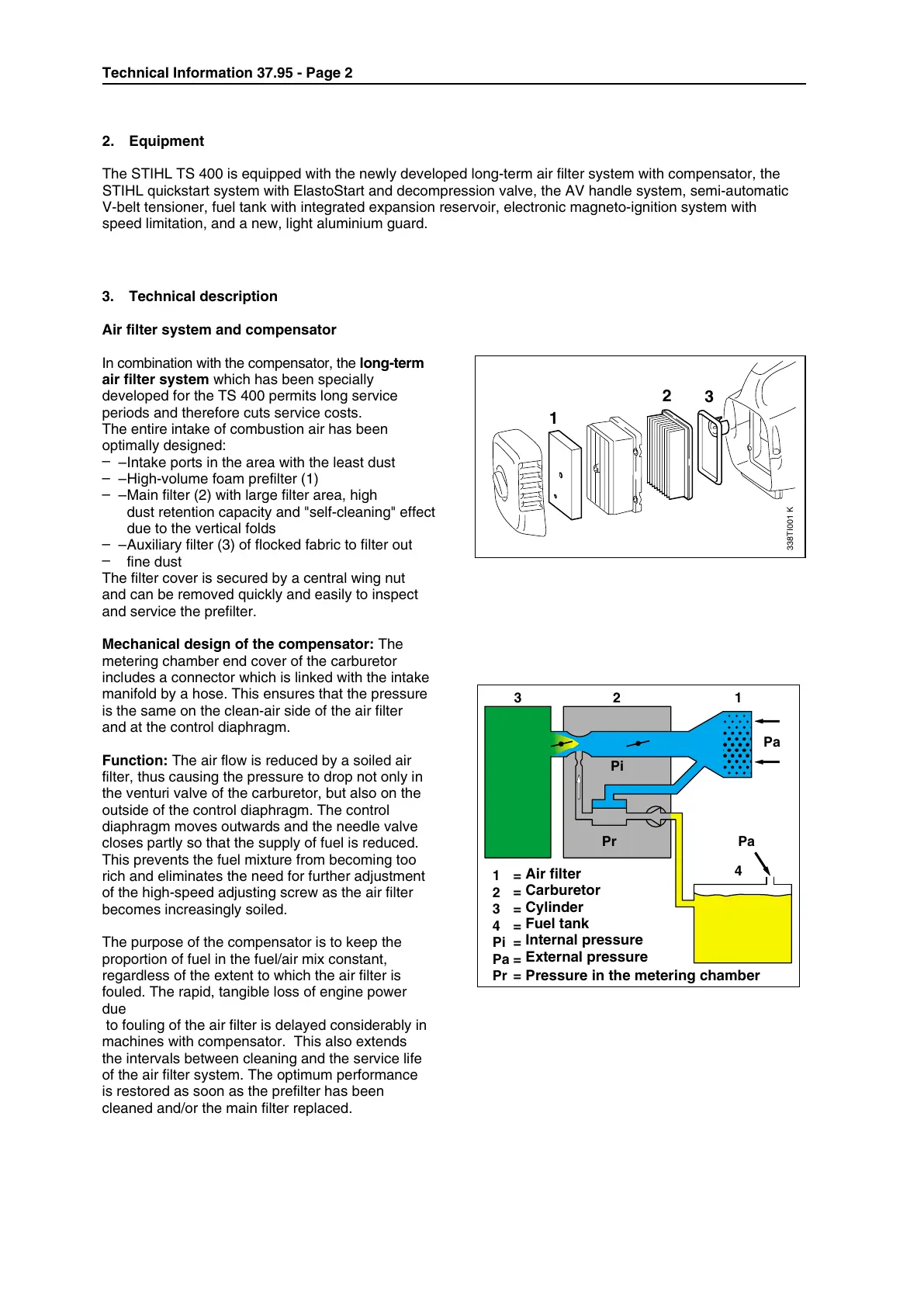

Mechanical design of the compensator: The

metering chamber end cover of the carburetor

includes a connector which is linked with the intake

manifold by a hose. This ensures that the pressure

is the same on the clean-air side of the air filter

and at the control diaphragm.

Function: The air flow is reduced by a soiled air

filter, thus causing the pressure to drop not only in

the venturi valve of the carburetor, but also on the

outside of the control diaphragm. The control

diaphragm moves outwards and the needle valve

closes partly so that the supply of fuel is reduced.

This prevents the fuel mixture from becoming too

rich and eliminates the need for further adjustment

of the high-speed adjusting screw as the air filter

becomes increasingly soiled.

The purpose of the compensator is to keep the

proportion of fuel in the fuel/air mix constant,

regardless of the extent to which the air filter is

fouled. The rapid, tangible loss of engine power

due

to fouling of the air filter is delayed considerably in

machines with compensator. This also extends

the intervals between cleaning and the service life

of the air filter system. The optimum performance

is restored as soon as the prefilter has been

cleaned and/or the main filter replaced.

Loading...

Loading...