TSA 230

English

23

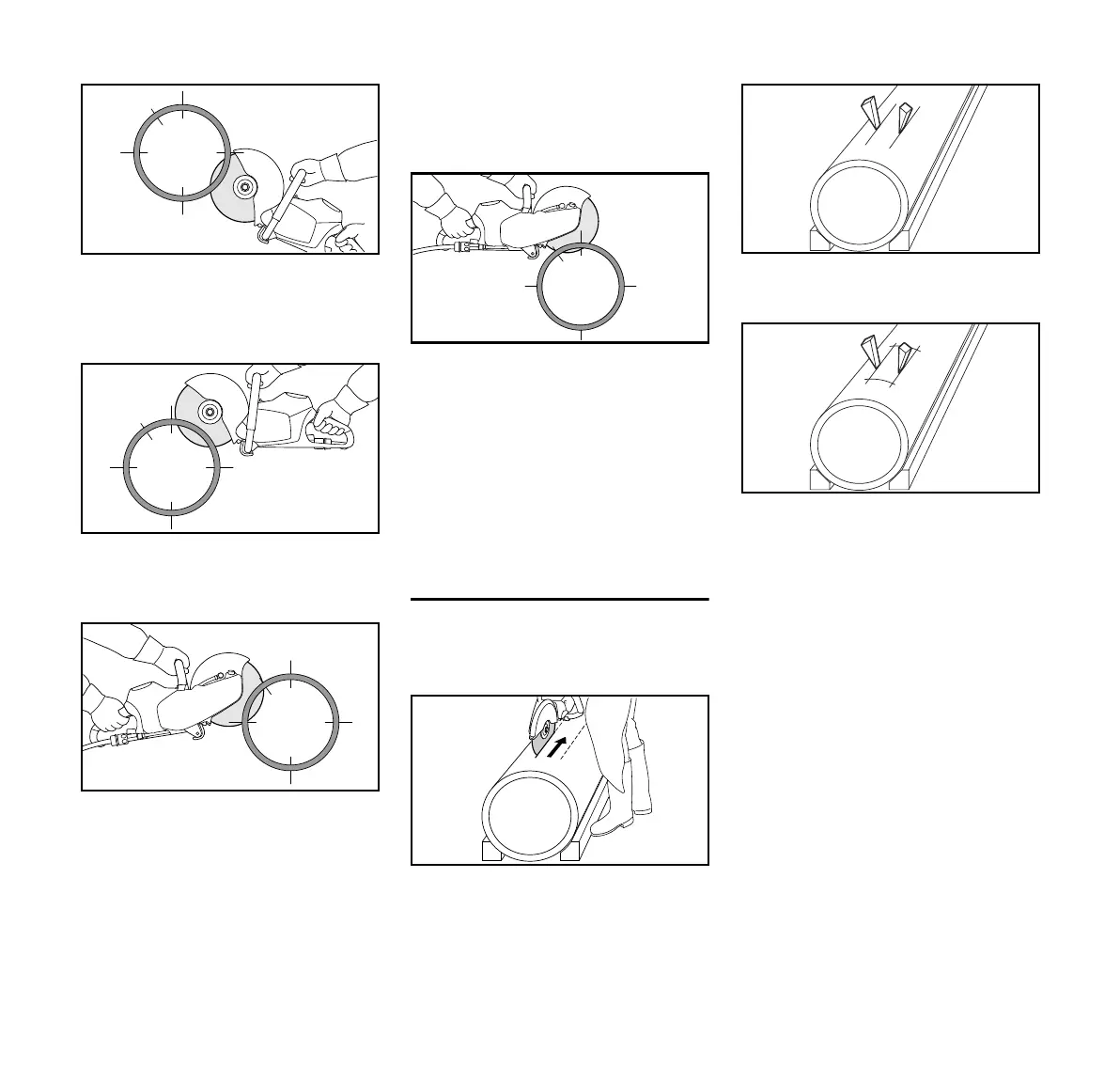

N Use the front and upper part of the

abrasive wheel for cutting the

opposite lower side. Make sure that

the cut at the bottom is complete.

N Next, make a first lateral cut on the

top half of the pipe, connecting with

the kerf from the bottom half.

N A second lateral cut is then made in

the marked area. To keep the pipe

from pinching during this cut, never

cut into the area of the final cut.

Only make the final top cut once all

bottom and lateral cuts have been

completed and connect with one

another.

N Always make the final separating

cut from the top (approx. 15 % of the

pipe circumference). If the

workpiece is properly supported, it

should not pinch when the cut is

completed. If there is any residual

pinching, however, it will be at the

bottom of the wheel, where it may

result in pull-away, but not in

kickback. Be alert for pull-away.

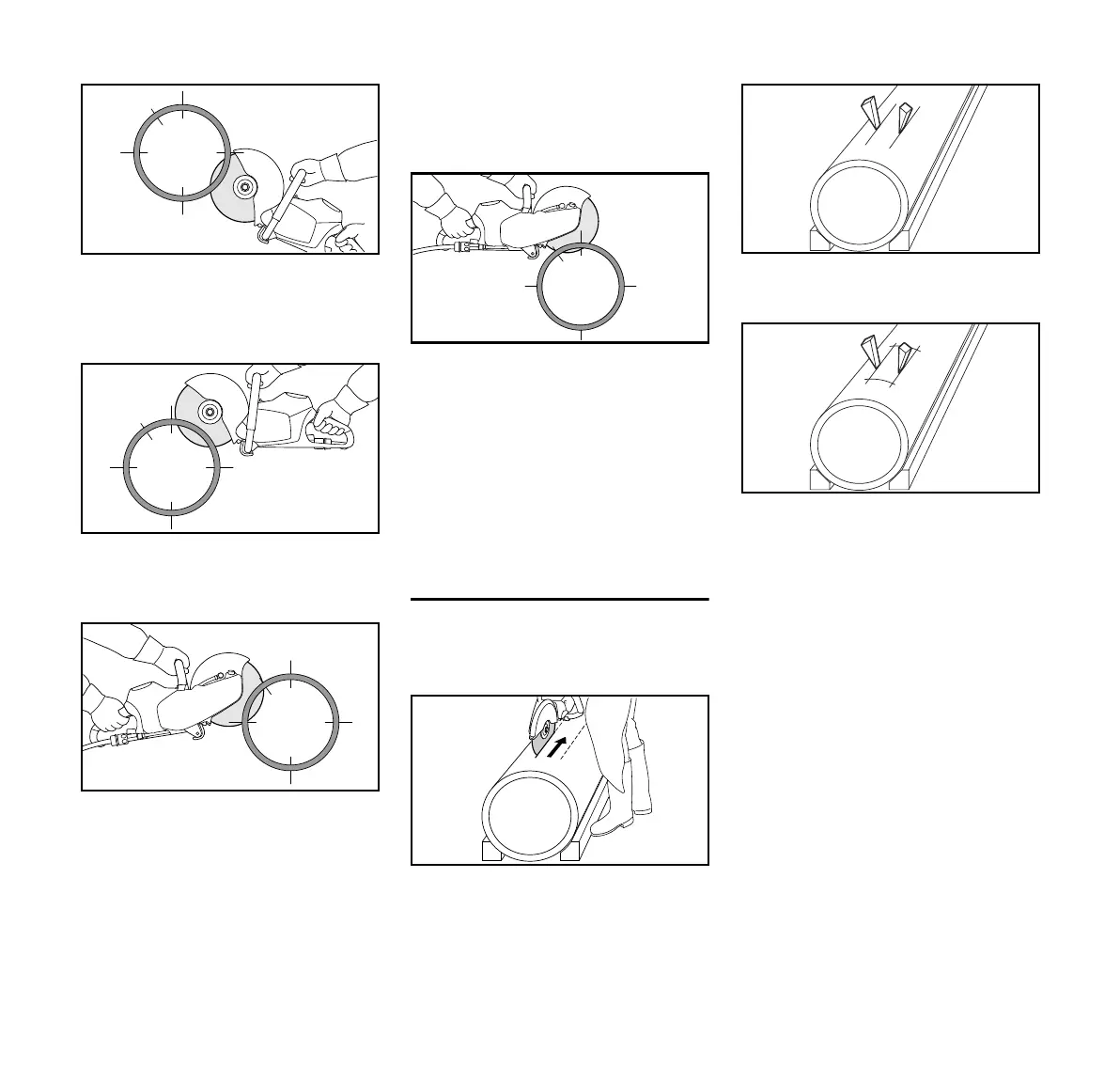

Concrete pipe – cut recess

Sequence of cuts (1 to 4) is important:

N First, cut hard-to-reach areas.

N Always make severing cuts so that

the abrasive wheel is not pinched.

N Use wedges and/or leave ridges

that are broken after cutting.

N If the severed part remains in the

recess after cutting (due to wedges,

ridges used), do not make any

further cuts – break the severed

part.

180BA025 AM

Loading...

Loading...