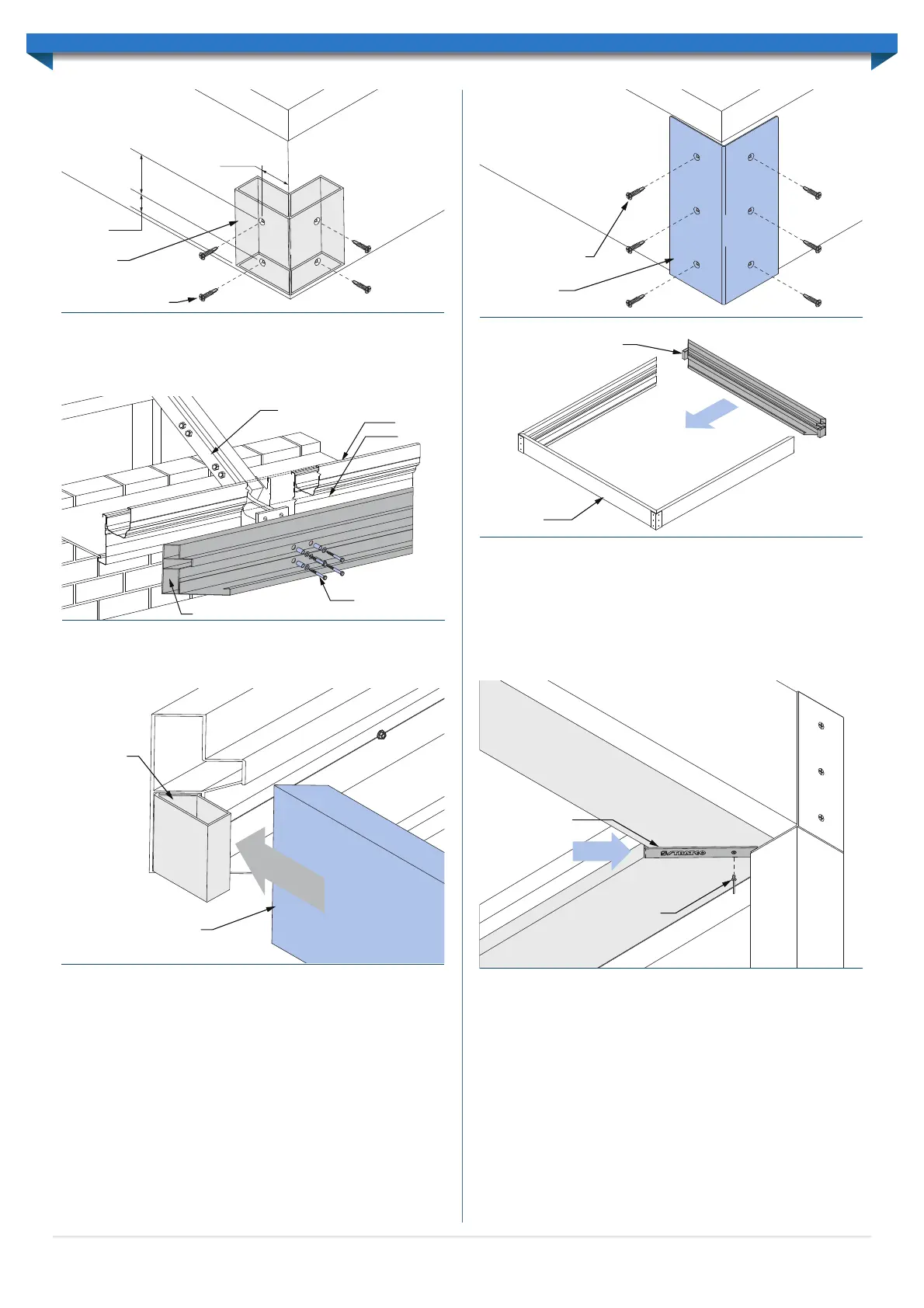

Fascia Beam Attachment

For units attached at the eaves, the Fascia beam is secured to the structure using Eaves

Fixing Brackets. Fix through the Eaves Fixing Brackets to the fascia beam using four M12

bolts with spacers and washers (Figure 2.8).

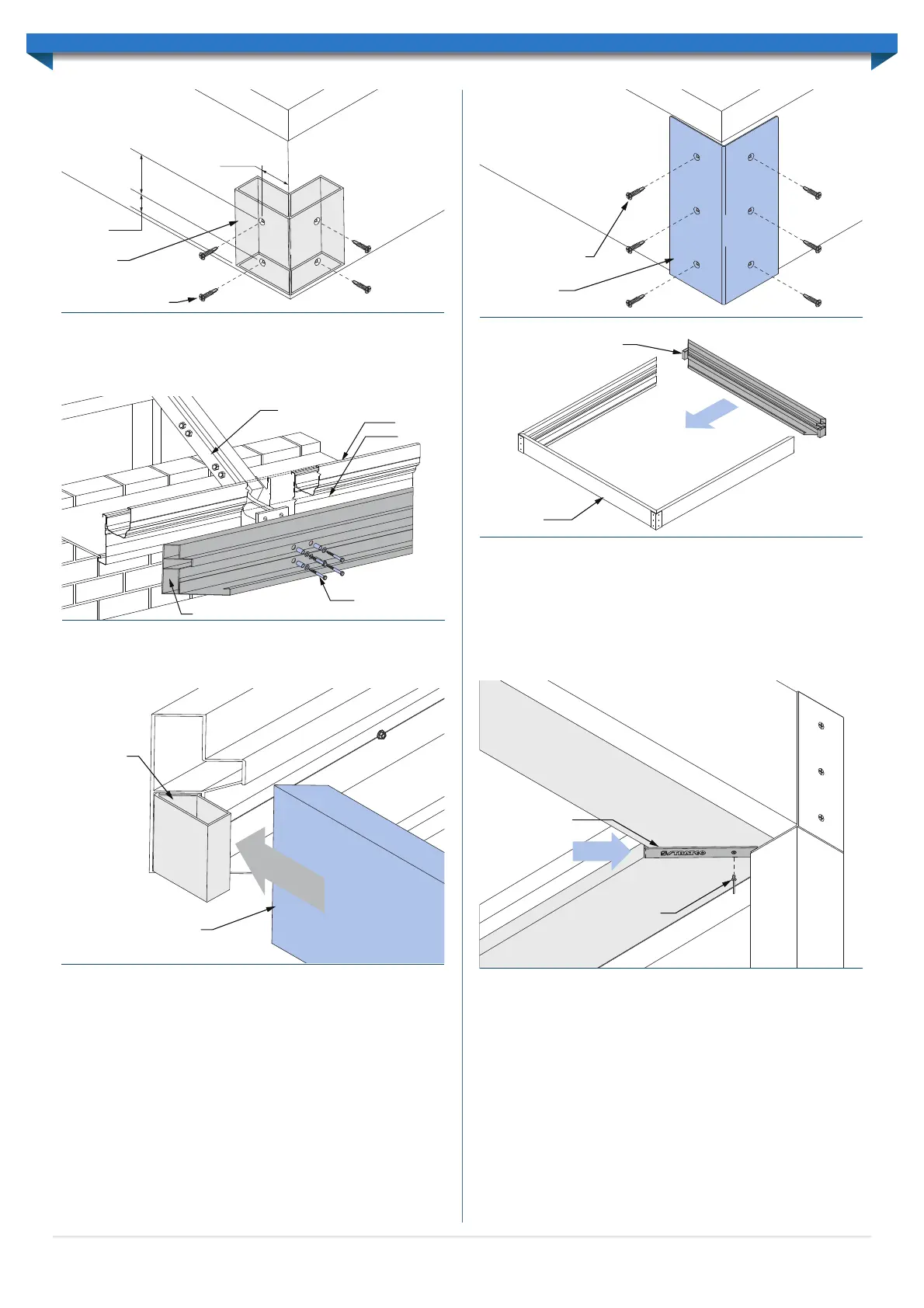

Side Beam Installation

The Side Beams must be propped in position at the required fall of 1° and over the pre-

installed Fascia Beam Corner Knuckle (Figure 2.9).

With the corner mitres aligned, ø3.2mm pilot holes must be drilled through the Side

Beams and the Corner Knuckles as per ‘Beam Preparation’. The pilot holes must also

be countersunk. Fasten the Side Beam to the Corner Knuckle using the 10gx30mm

stainless steel countersunk self-tapping screws provided (Figure 2.7).

Note: All screws within the unit must be fastened by hand using a screw-driver, or a

low-torque, low-speed drill.

Fascia Beam to Side Beam connections also require additional fastening using external

Corner Joiners. Corner Joiners must be fixed to the Fascia and Side Beams using

10gx30mm stainless steel countersunk self-tapping screws (Figure 2.10).

Once Side beams are attached the remaining Header Beam must be fixed using Corner

Knuckles as described in the previous paragraphs (Figure 2.11).

Gutter Straps

When the entire framework is erected each gutter mitre at corners can be concealed

using the Gutter Straps provided. Gutter Strap variations will be provided for corners

with posts (notched straps) and corners without (full-length straps). Slide the Gutter

Straps over the Mitres and drill a ø3.2mm pilot hole through the gutter. Fix the Gutter

strap to the Gutters using a 3.2mm rivet (Figure 2.12). If the rivet does not grip to

the gutters, a ø3mm washer may be required to sit inside the gutters to assist in fixing.

Internally seal each gutter mitre with silicone as required.

In the downpipe corner Gutter Straps will interfere with the downpipe. The interfering

gutter strap will need to be notched on-site to allow clearances. An angle grinder can be

used to trim the Gutter Strap to suit.

Multiple-Bank Frame Installation

In some instances a unit will feature multiple louvre banks. When this occurs separate

back-to-back banks are used with the banks fastened to one another. Louvres may run

parallel or perpendicular to the back-to-back beams.

When multiple banks are required all beams will be pre-mitred to facilitate installation

before going to site.

Where banks are adjacent to one another the back-to-Back beams are fixed together

using 10g x 30mm stainless steel countersunk self-tapping screws at a maximum spacing

of 600mm centres (Figure 2.13).

Gutter Strap

Rivet to gutter

Figure 2.12

Header Beam assembly

Fascia /

Attachment

Beam

Figure 2.11

Figure 2.9

Corner

Knuckle

Side Beam

10gx30 stainless steel

countersunk screws

Corner Joiner

Figure 2.10

Attachment Beam

Fascia

Gutter

Adjustable Rafter Strengthening Bracket

Four M12 Bolts with

spacers & washers

Figure 2.8

Corner

Knuckle

10g x 30mm stainless steel

countersunk screws

Fascia beam Side beam

60mm

30mm

50mm

Figure 2.7

6

Loading...

Loading...