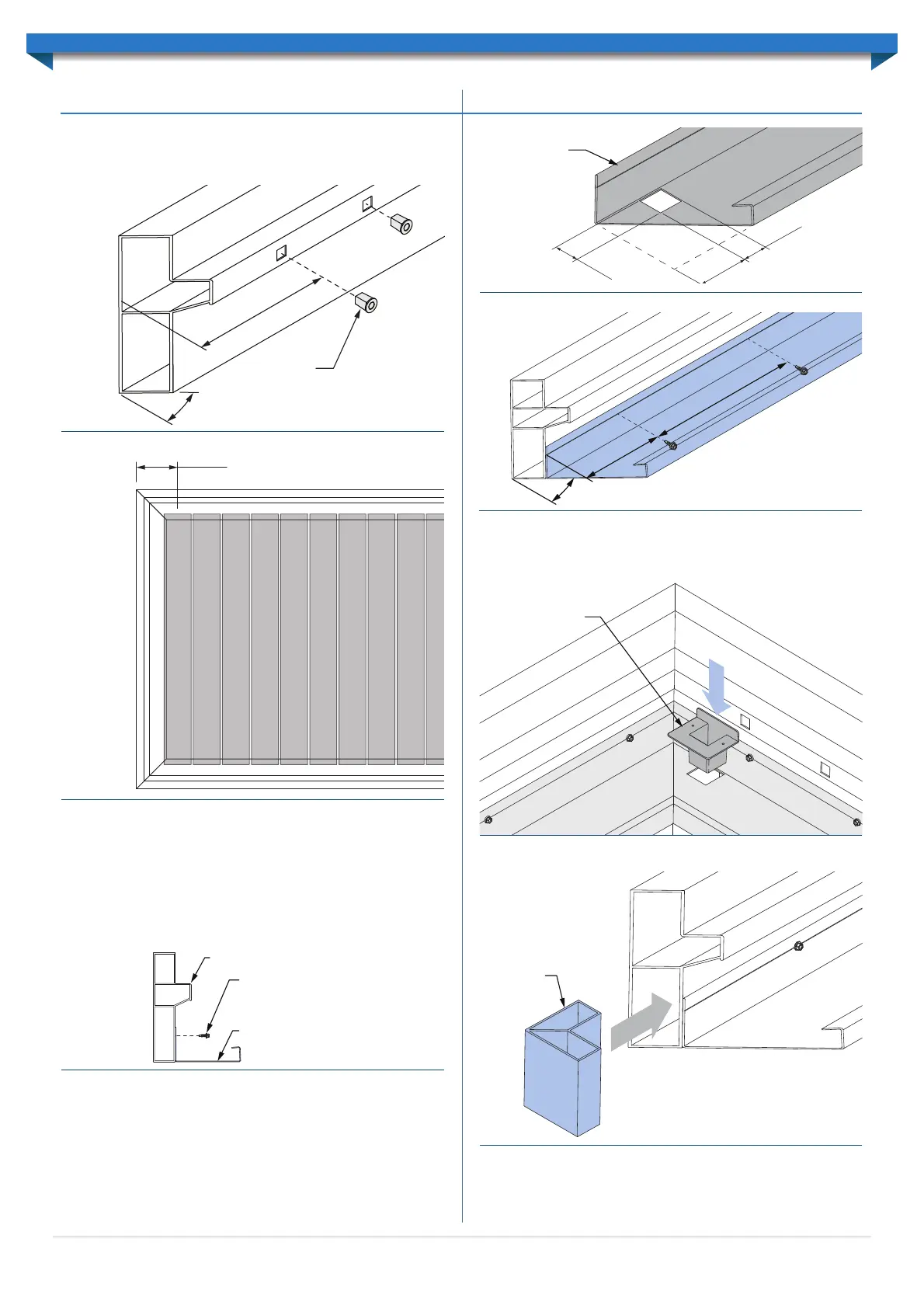

Note: Please ensure to follow the site plans supplied to ensure the mounting beams

are installed in the correct orientation. The Datum end of beams will be identifiable by

measuring the first mounting hole centre 270mm in from the end of the beam (Figure

2.0 & Figure 2.1).

Beam Preparation

The framework must be assembled out from the fascia beam already fixed to the

structure. If the unit is Freestanding the beams must be propped with two posts secured

as per the section ‘Post Installation’.

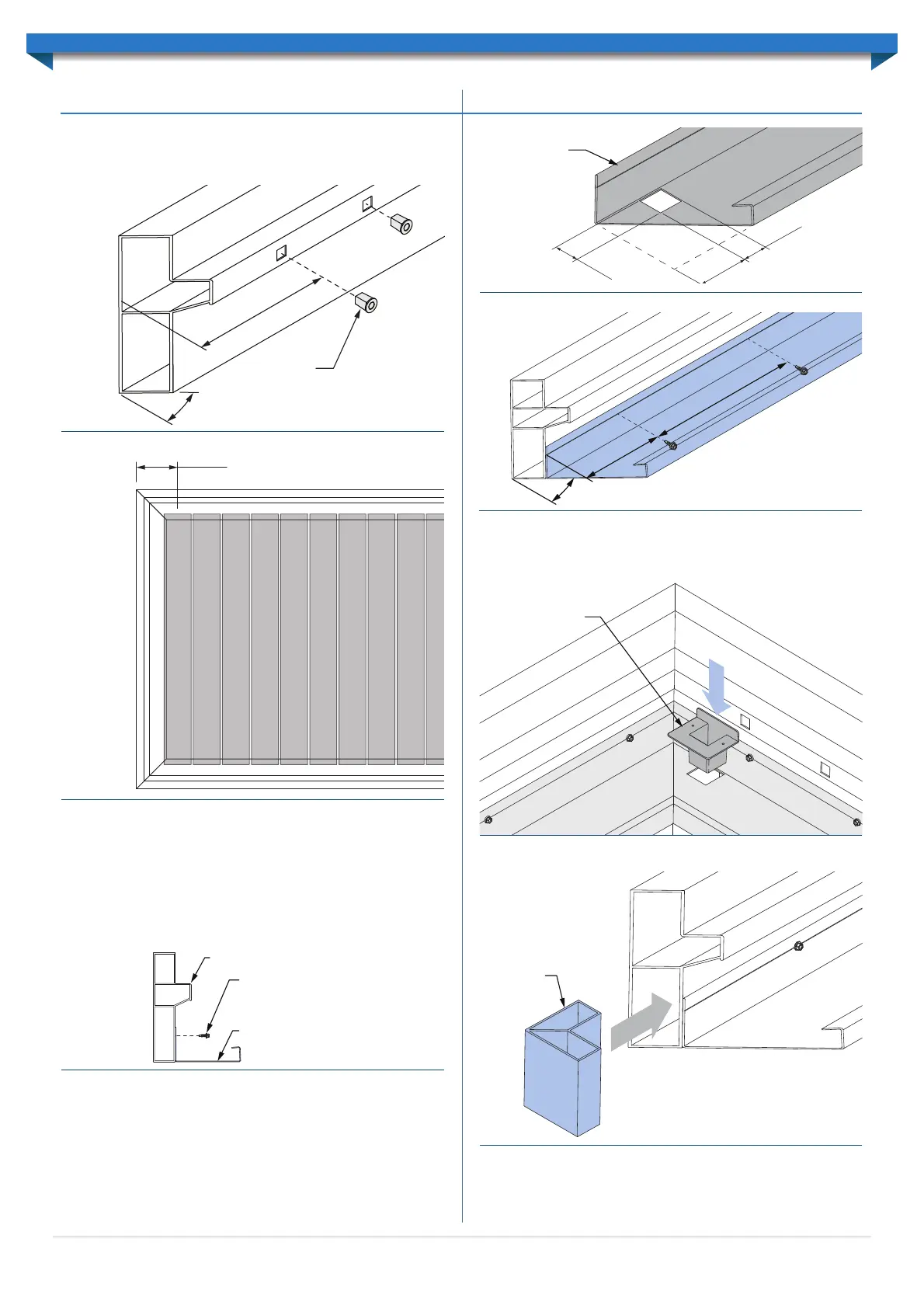

Internal box gutters will sit inside the assembled framework with the bottom face of the

gutters flush with the bottom face of the beams (Figure 2.2). Gutters will be supplied

already mitred to suit the frame size. Gutters must be fixed to each beam before the

framework can be erected.

Before installing the gutters the downpipe outlet location(s) must be determined. A

rectangular 45x45mm cut-out must be created on the header-beam gutter (Figure 2.3).

Make sure the cut-out is aligned with the rear internal face of the gutter.

Begin gutter installation by placing & clamping a length of the pre-mitred gutter against

the corresponding beam. Secure the gutter to the framework using 12x20 Self-Drilling

screws with Neoprene washers at 500mm centres (Figure 2.4). The end fixings must be at

least 100mm in from each end. All gutter end mitres should be flush with the beam mitres.

Continue installing the remaining gutters using the same method. Insert the Downpipe

Outlet(s) within the pre-cut holes and secure using two 3.2mm rivets (Figure 2.5). Seal

around the outlet with silicone as required.

At each Beam-to-Beam join a Corner Knuckle must be internally fitted (Figure 2.6).

Create ø3.2mm pilot holes with countersinks and fix the Corner Knuckle through

the external face of the Fascia beam using two 10gx30mm stainless steel countersunk

self-tapping screws (Figure 2.7). Countersinks should have an outside diameter of

approximately 8mm to allow the screw head to sit flush.

12x20 self-drilling screws

with neoprene washers at

500mm centres

Gutter

Beam

Figure 2.2

5

0m

m

4

5m

m

4

5m

m

Gutter

Figure 2.3

Figure 2.4

45°

5

0

0m

m

c

e

n

t

r

e

s

10

0m

m

m

i

n

.

Downpipe Outlet

(rivet from

underside of gutter)

Figure 2.5

Corner

Knuckle

Figure 2.6

270mm

@

Datum

45°

Mounting

Bushes

Figure 2.0

Figure 2.1

270mm

DATUM

5

FRAMEWORK ASSEMBLY

Loading...

Loading...