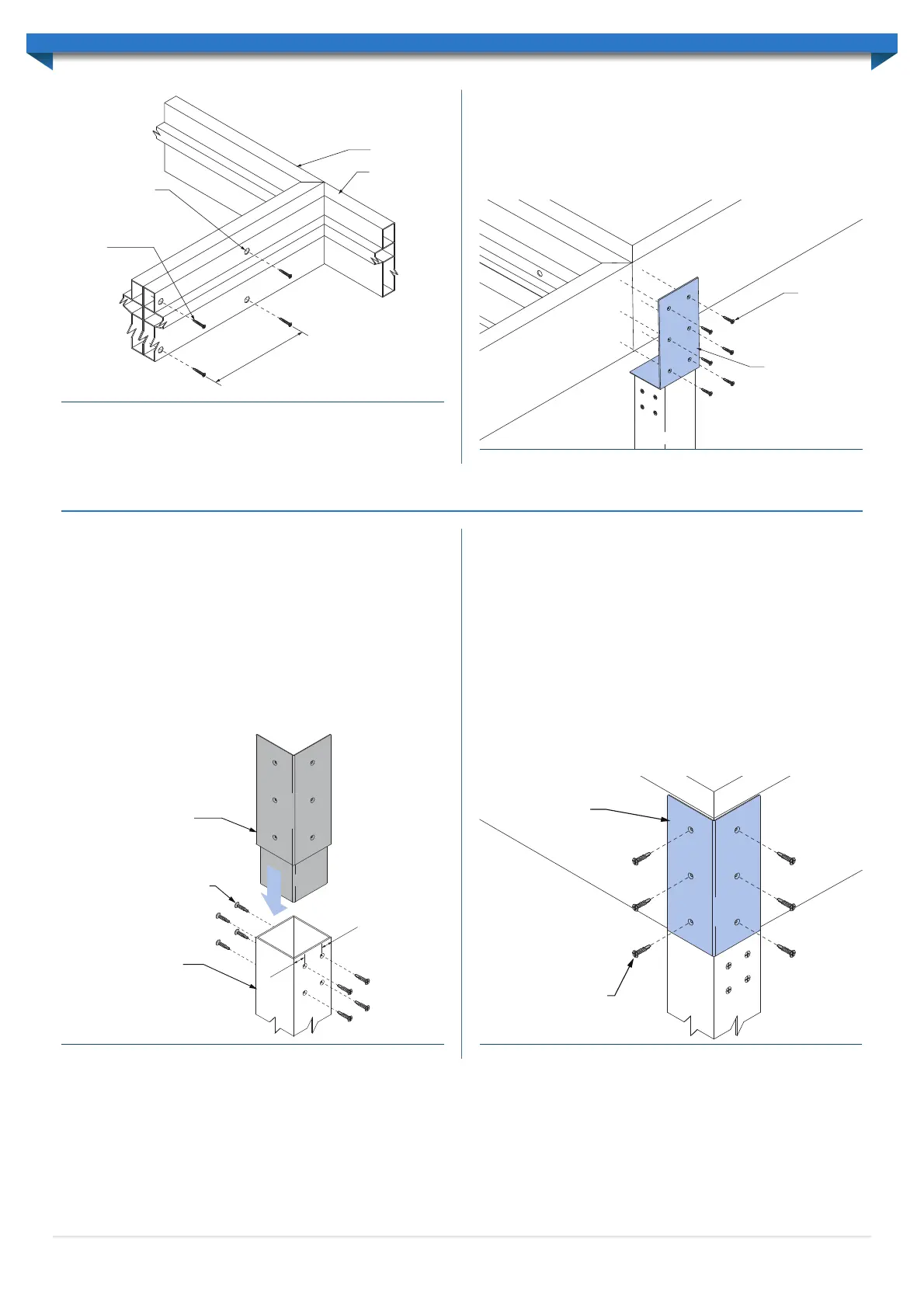

A ø10mm pilot hole must be made to allow fastening through the back-to-back

wall sections. These pilot holes are sealed with a cover flashing (see ‘Installing Cover

Flashings’).

10g x 30mm stainless

steel countersunk

screws

10mmø pilot hole

Bank 1

Bank 2

M

A

X. 600mm

C

ENT

R

ES

Note: Gutters omitted for clarity

Figure 2.13

Figure 2.14

10g x 30mm

stainless steel

countersunk

screws

Inline Post-to-Beam

Bracket

Bank 2

Bank 1

Note: All screws within the unit must be fastened by hand using a screw-driver, or a

low-torque, low-speed drill.

A post is connected using Inline Post-to-Beam brackets along the header beam where

back-to-back banks meet (Figure 2.14).

See ‘Post Installation’ for further post fixing details.

7

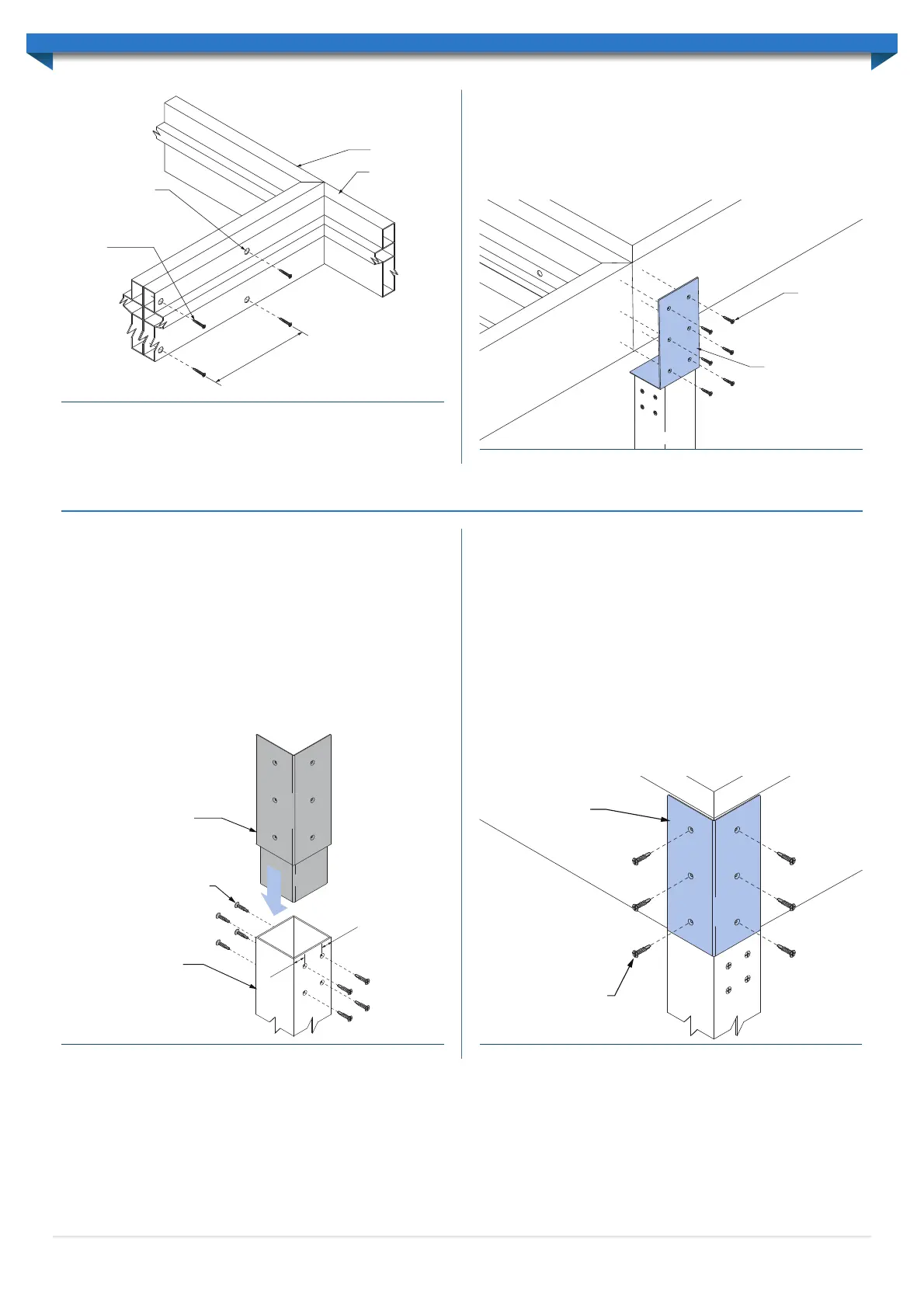

Figure 3.0

Post-Beam

Corner Bracket

10gx30 stainless steel

countersunk screws

Corner Post

3

0

mm

30

mm

Post-Beam

Corner Bracket

10gx30 stainless steel

countersunk screws

Figure 3.1

100x100 SHS Posts are used to support the Allure framework. Once the framework is

assembled and set at the correct pitch, the post height measurements must be taken.

Posts sit beneath the beams and can either be fixed into concrete footings or onto

concrete. Refer ‘Footing Installation’ for further details regarding Post fixing (see below).

Posts must be cut to the length determined from the framework height measurements

(refer ‘Footing Installation’).

Post-to-Beam Brackets must be fitted at the top of each post. Corner and Inline Post-

to-Beam brackets are supplied as determined by the design of the unit. Sit the Post-

to-Beam Bracket within the Post and drill ø3.5mm pilot holes centralised and 25mm

& 65mm down from the top of the Post on two opposing faces (Figure 3.0). These

holes must also be countersunk. Countersinks should have an outside diameter of

approximately 8mm to allow the screw head to sit flush.

Fix the Post-to-Beam Bracket to the post using 10gx30mm stainless steel countersunk

self-tapping screws (Figure 3.0).

Note: All screws within the unit must be fastened by hand using a screw-driver, or a

low-torque, low-speed drill.

Position posts at the required location beneath beams. Before fixing the Post-to-Beam

Brackets to the Framework the Posts must be measured plumb using a spirit level.

Drill pilot holes through to the Beam as per the locations determined on the Post-to-

Beam Bracket saddle. Fix the Post-to-Beam bracket to the Beam(s) using 10gx30mm

stainless steel countersunk self-tapping screws (Figure 3.1).

Note: All screws within the unit must be fastened by hand using a screw-driver, or a

low-torque, low-speed drill.

Inline Post-Beam bracket connections are fixed using the same process.

POST INSTALLATION

Loading...

Loading...