8

Post

Duramax General

Purpose Epoxy or

equivalent

Brick

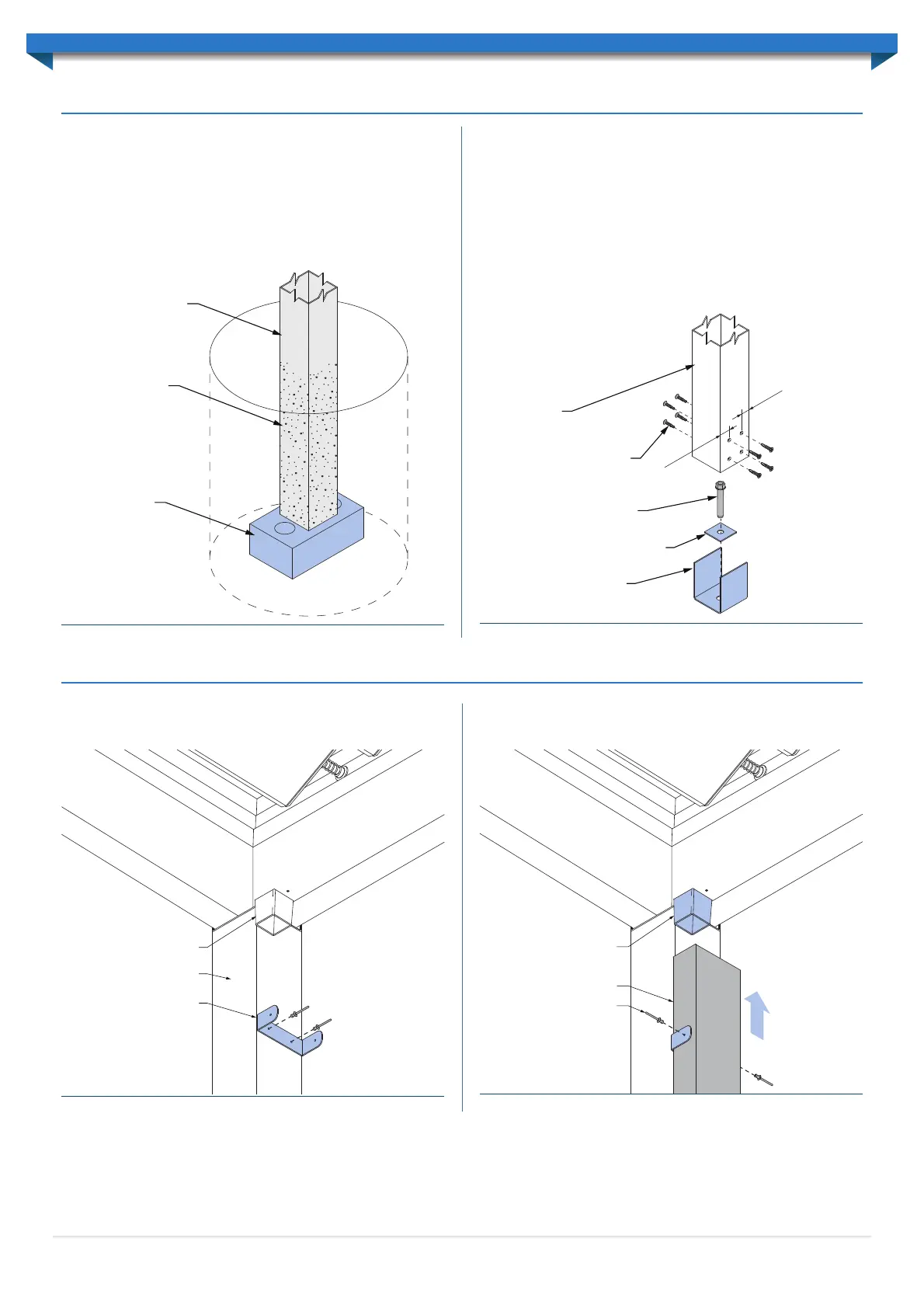

Figure 4.0

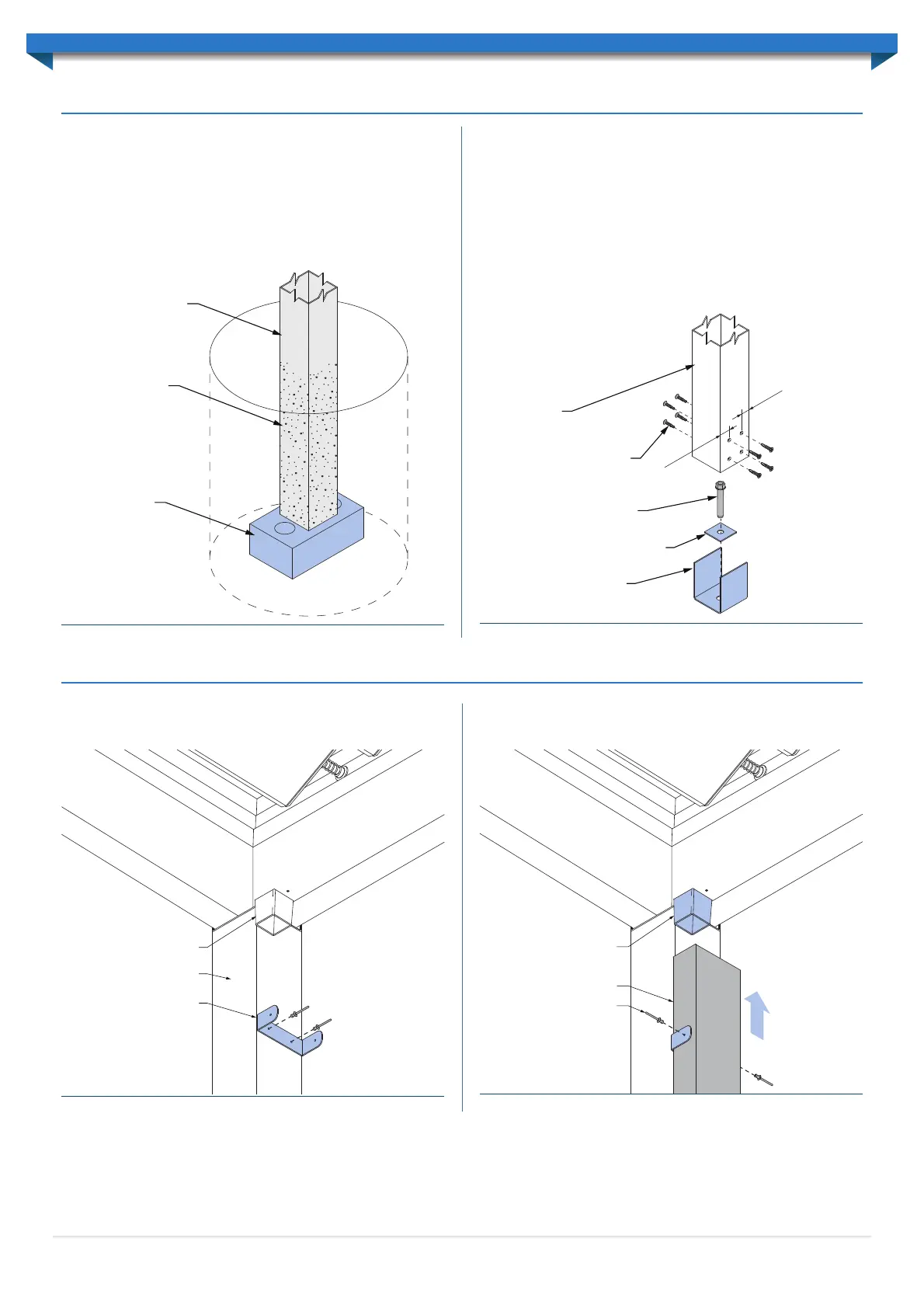

Figure 4.1

10gx30 stainless steel

countersunk screws

M12x120 anchor bolt

100x100 Post Shoe

50x50x6.0mm Washer Plate

Post

3

0

mm

3

0

mm

FOOTING INSTALLATION

Into Concrete Footings

If fixing the columns into the ground, dig the holes to the specified size. Place a half brick

in the bottom of the hole (Figure 4.0). Measure from the underside of the beam to the

top of the half brick and cut posts to this length at each post location. Any area of the

posts in contact with the concrete must be coated with Duramax General Purpose

Epoxy (or an equivalent).

Use construction props or bracing to hold columns in position, but do not concrete

the post-holes at this stage.

Onto Concrete Footings

Where posts are fixed onto concrete a Post Shoe will be used.

Fix the Post Shoe to concrete using one M12x120mm Anchor Bolt in conjunction with

a 50x50x6.0mm washer plate (Figure 4.1). Fasten the post to the Post Shoe with four

10gx30mm stainless steel countersunk self-tapping screws on either side (Figure 4.1).

Ensue screws are 30mm in from the Post edges. Countersinks should have an outside

diameter of approximately 8mm to allow the screw head to sit flush.

Note: All screws within the unit must be fastened by hand using a screw-driver, or a

low-torque, low-speed drill.

Use construction props or bracing to hold columns in position, but do not bolt to the

concrete slab at this stage.

100x50mm downpipes must be installed beneath each downpipe outlet. Downpipes will

run in-line with unit posts.

Fix the downpipe strap to the post using the rivets provided (Figure 5.0).

Downpipe

Downpipe outlet

Secure downpipe

with rivets

Figure 5.1

Post

Downpipe strap

Downpipe outlet

Figure 5.0

Slide the downpipe up and around the downpipe outlet (Figure 5.1). Secure 100x50mm

downpipe to the downpipe strap using rivets.

DOWNPIPE INSTALLATION

Loading...

Loading...