8

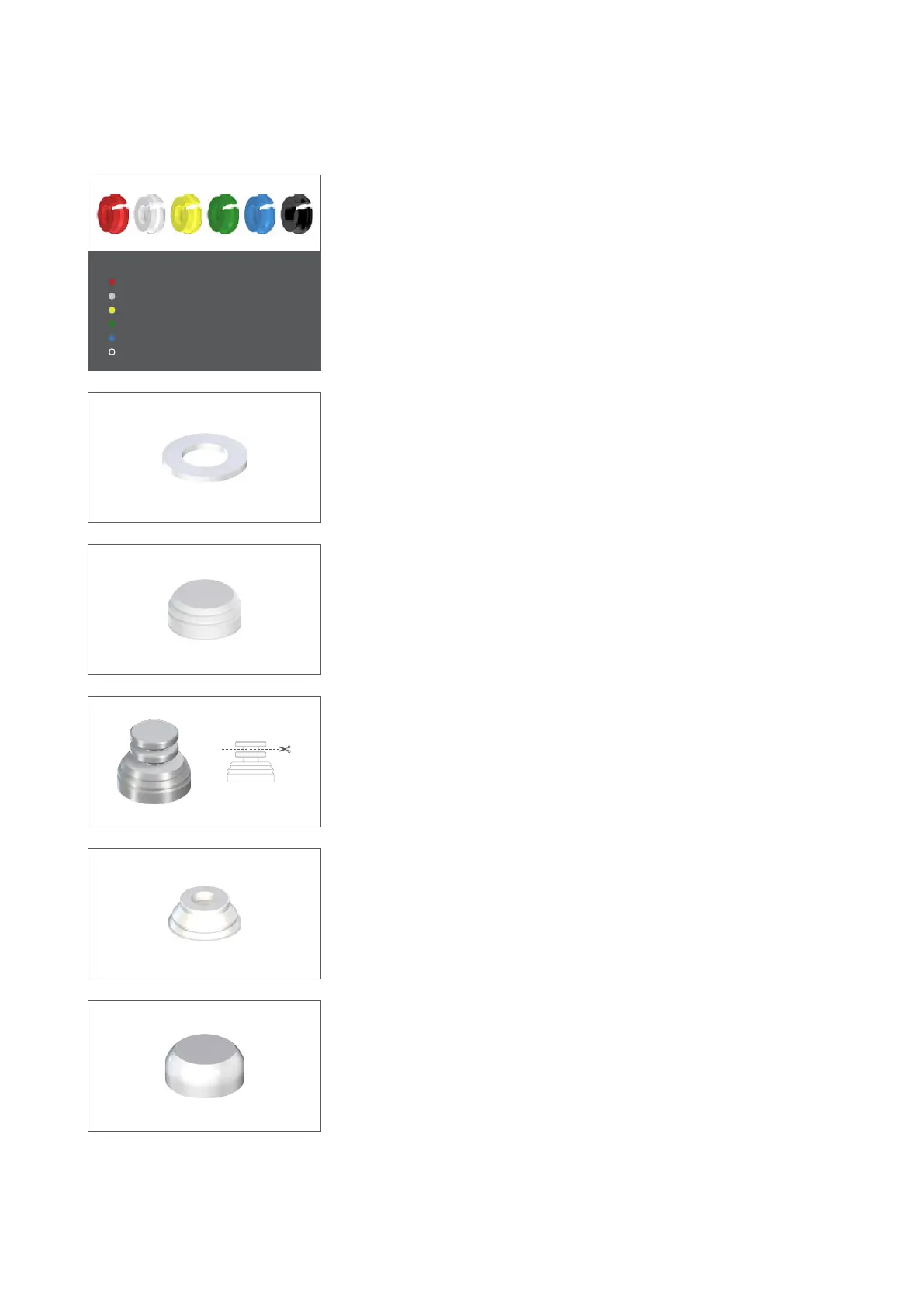

. Special featured Novaloc® Components

Retention insert color Retention

red, extra light approx. 300 g

white, light approx. 750 g

yellow, medium approx. 1200 g

green, strong approx. 1650 g

blue, extra-strong approx. 2100 g

black, ultra-strong approx. 2550 g

Novaloc® Retention Inserts

The Novaloc® matrix system allows for a prosthetic insertion of up to

+/- 20° divergence, meaning 40° between two Novaloc® Abutments.

Note:

It is recommended to use the light retention force first (white). In

case it feels too loose for the patient, exchange with inserts with a

higher retention force.

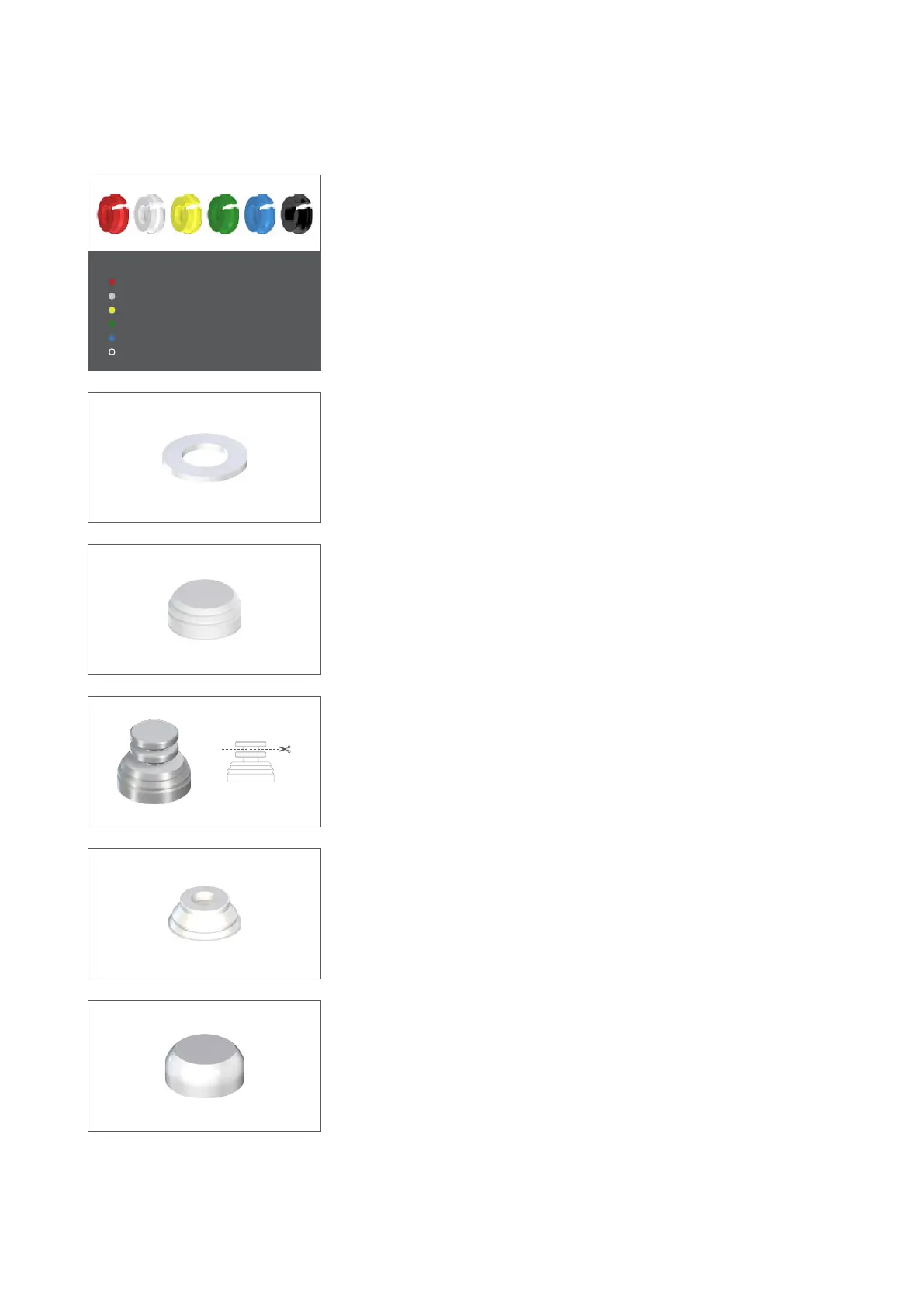

Novaloc® Mounting Collar

The Mounting Collar blocks out the area surrounding the abutment,

preventing that resin or a bonding agent flows into the Matrix Hous-

ing and imbedding the abutment.

Novaloc® Matrix Housing, PEEK

The neutral-colored PEEK Matrix Housing is used for extremely labi-

al or buccal implant positions preventing grey irritation coming from

a titanium Matrix Housing.

Novaloc® Matrix Housing with attachment option

This Matrix Housing offers an extended attachment option. It is

used for low-lying abutment heights or in situations requiring more

retention. The attachment may be shortened according the required

height.

Novaloc® Mounting Insert

The Novaloc® Mounting Insert protects the interior of the Novaloc®

Matrix Housing and keeps it in place during processing. Further-

more, it also prevents any resin or bonding agents of entering into

the Novaloc® Matrix Housing during fixation.

Novaloc® Processing Spacer

The Novaloc® Processing Spacer is a placeholder for the Novaloc®

Matrix Housing. It is used for the model-cast, cast metal-reinforced

denture or if the Novaloc® Matrix Housing shall be polymerized into

the overdenture chair-side.

490.115.indd 8 24/06/2019 14:02

Loading...

Loading...