Suburban DynaPack A&E Manual 07/2019 Rev.6

21

S SERIES

CONDENSATE DRAIN

The DynaPack unit and wall sleeve each have their own drain. The unit drain is

for the condensate developed by the evaporator coil. It needs to be trapped and

routed to the building drain system. Use 3/4" pvc pipe and fittings (field

supplied).

The wall sleeve is equipped with a drain pan that collects rain water entering

the wall sleeve and the unit condenser coil area. At the time of installation of

the wall sleeve, this drain can be directed directly outside or turned inside and

routed to the building drain system. If the wall sleeve drain is routed to the

building sewer system then it must be trapped to prevent sewer gasses

from escaping.

DUCT WORK

The duct work for the dwelling should be designed for the lowest possible

static pressure to reduce energy usage and noise. Table 4 lists the approximate

cfm delivery of the units on each of the indoor blower speeds. Table 5 lists the

recommended heating and cooling speeds with its approximate cfm delivery.

Use both tables to properly design the duct system for both heating and

cooling cfm.

(continued on next page)

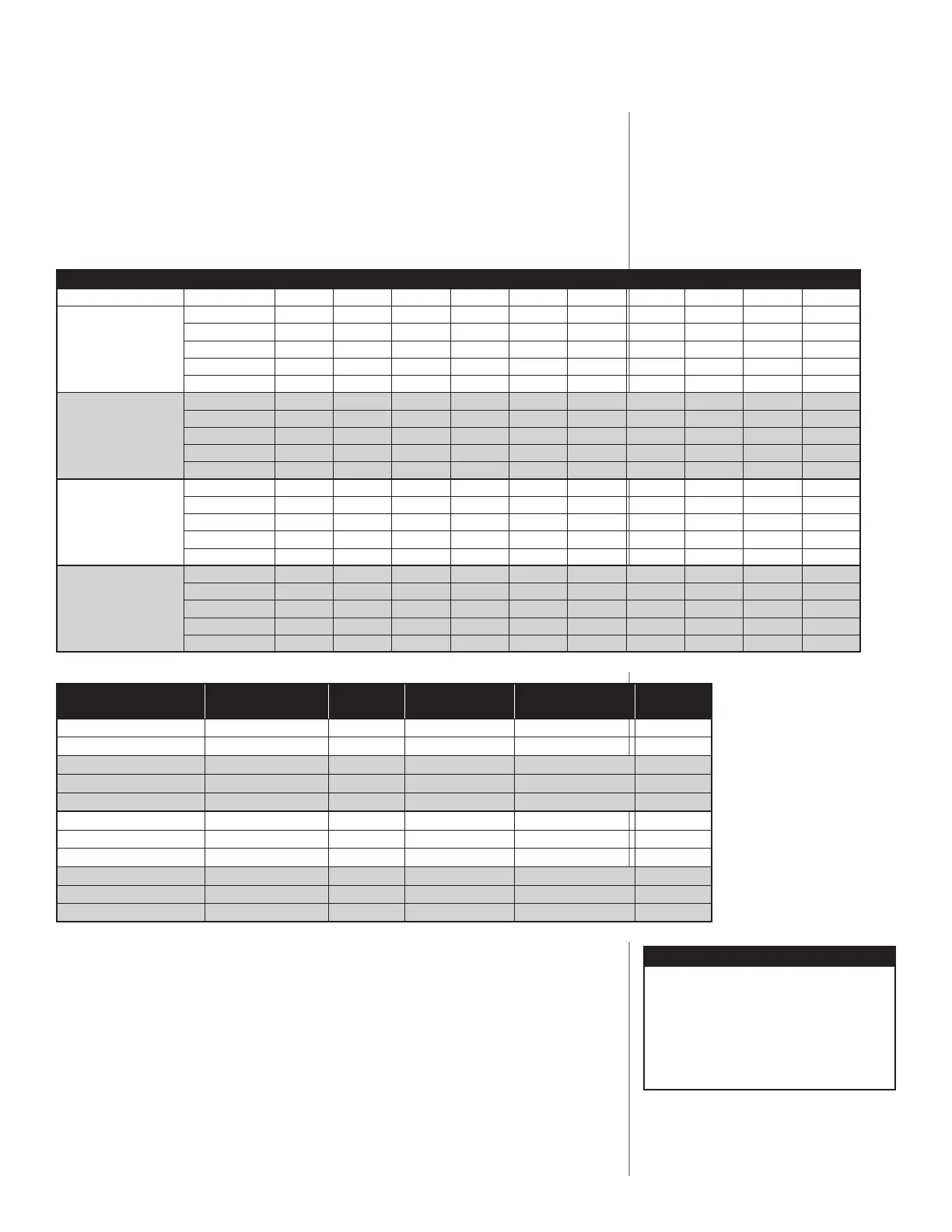

S SERIES INDOOR CFM vs STATIC PRESSURE (Dry coil + no air filter)

MODEL NUMBER

Blower Speed 0.10" wc 0.15" wc 0.20" wc 0.25" wc 0.30" wc 0.40" wc 0.50" wc 0.60" wc 0.70" wc 0.80" wc

DYPA12AC3A

LO

497 473 448 424 400 348 296 247 212 160

MED LO

577

562 547 522 497 458 415 357 317 281

MED 757

748 739 716 692 670 635 586 558 521

MED HI 937

920 905 888 872 852 827 790 728 677

HI 1060

1050 1042 1015 977 927 876 824 758 700

DYPA18AC3A

LO

512 491 469 428 387 320 285 250 213 179

MED LO

596

568 540 522 504 447 415 381 324 291

MED 773

761 748 730 711 675 640 622 586 550

MED HI 972

955 938 927 915 874 850 825 796 766

HI 1108

1091 1074 1057 1039 1002 970 917 868 796

DYPA24AC3A

LO

504 483 461 420 379 312 252 207 N/R N/R

MED LO

588 560 532 514 496 439 377 320 262 202

MED 765

753 740 722 703 667 622 572 532 482

MED HI 964

947 930 919 907 866 828 782 757 702

HI 1100

1083 1066 1049 1031 994 962 922 882 827

DYPA30AC3A

LO

490 465 440 415 385 310 225 170 N/R N/R

MED LO

570

540 520 500 476 415 365 310 250 205

MED 768

755 741 732 704 666 621 580 535 500

MED HI 934

922 913 895 873 835 800 760 730 690

HI 1064

1046 1017 1009 995 965 935 900 875 828

TABLE 4

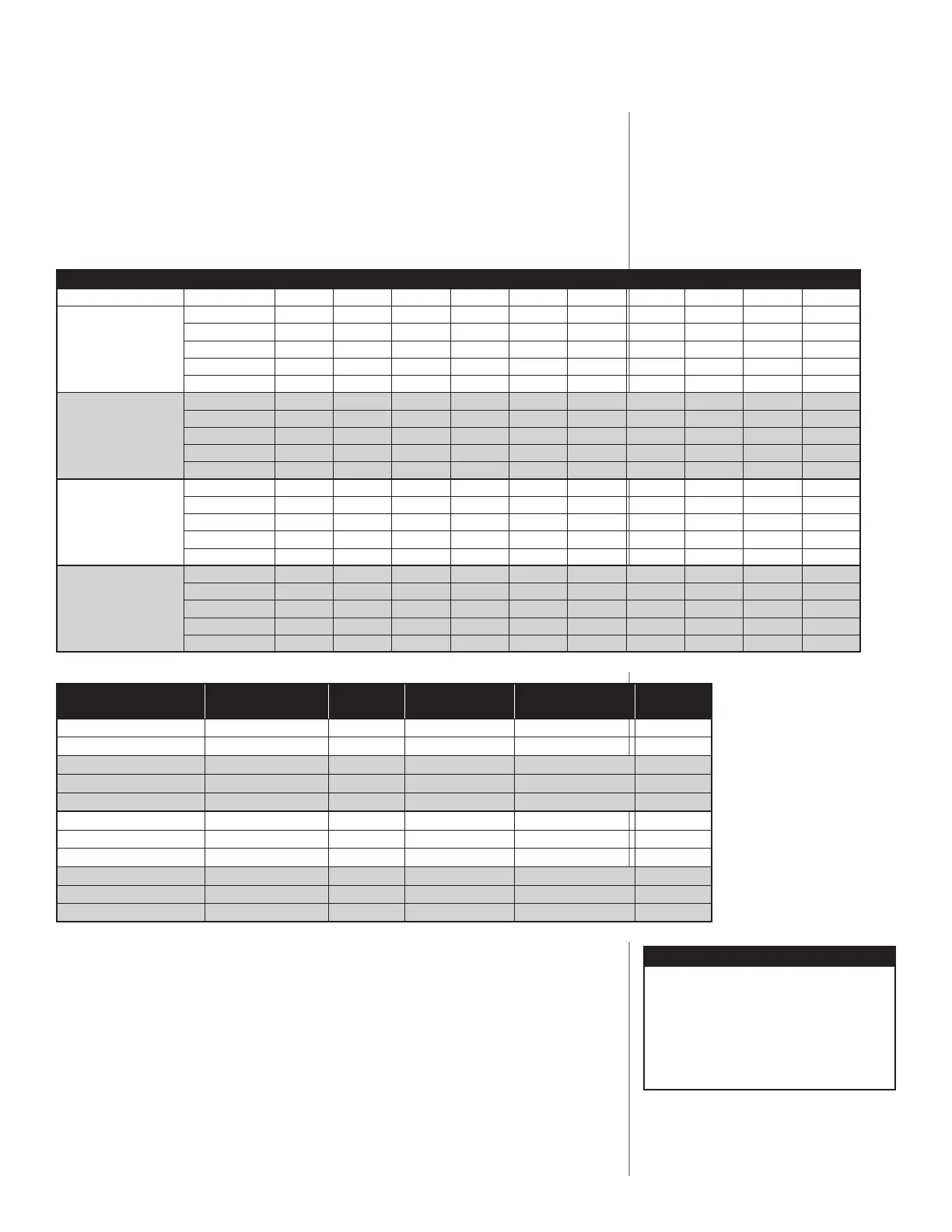

MODEL NUMBER

Recommended

Heating Speed

Approx.

CFM

Approx.

Temp Rise ºF

Recommended

Cooling Speed

Approx.

CFM

DYPA12AC3A036

MEDIUM 700 38 LOW 400

DYPA12AC3A048

MEDIUM 700 50 LOW 400

DYPA18AC3A036

MEDIUM 700 38 MEDIUM LOW 550

DYPA18AC3A048

MEDIUM 700 50 MEDIUM LOW 550

DYPA18AC3A060

MEDIUM HIGH 900 50 MEDIUM LOW 550

DYPA24AC3A036

MEDIUM 700 38 MEDIUM 700

DYPA24AC3A048

MEDIUM HIGH 900 40 MEDIUM 700

DYPA24AC3A060

MEDIUM HIGH 900 50 MEDIUM 700

DYPA30AC3A036

MEDIUM 700 38 MEDIUM HIGH 900

DYPA30AC3A048

MEDIUM HIGH 900 40 MEDIUM HIGH 900

DYPA30AC3A060

MEDIUM HIGH 900 50 MEDIUM HIGH 900

TABLE 5

NOTE

Follow local codes and standards

when designing duct runs to deliver

the required airflow. Minimize noise

and excessive pressure drops caused

by duct aspect ratio changes,

bends, dampers and outlet grilles in

duct runs.

Loading...

Loading...