2-4

#7013455 - Revision A - April, 2009

Installation Information

International W

International W

ine Storage

ine Storage

(ICBWS)

(ICBWS)

Series

Series

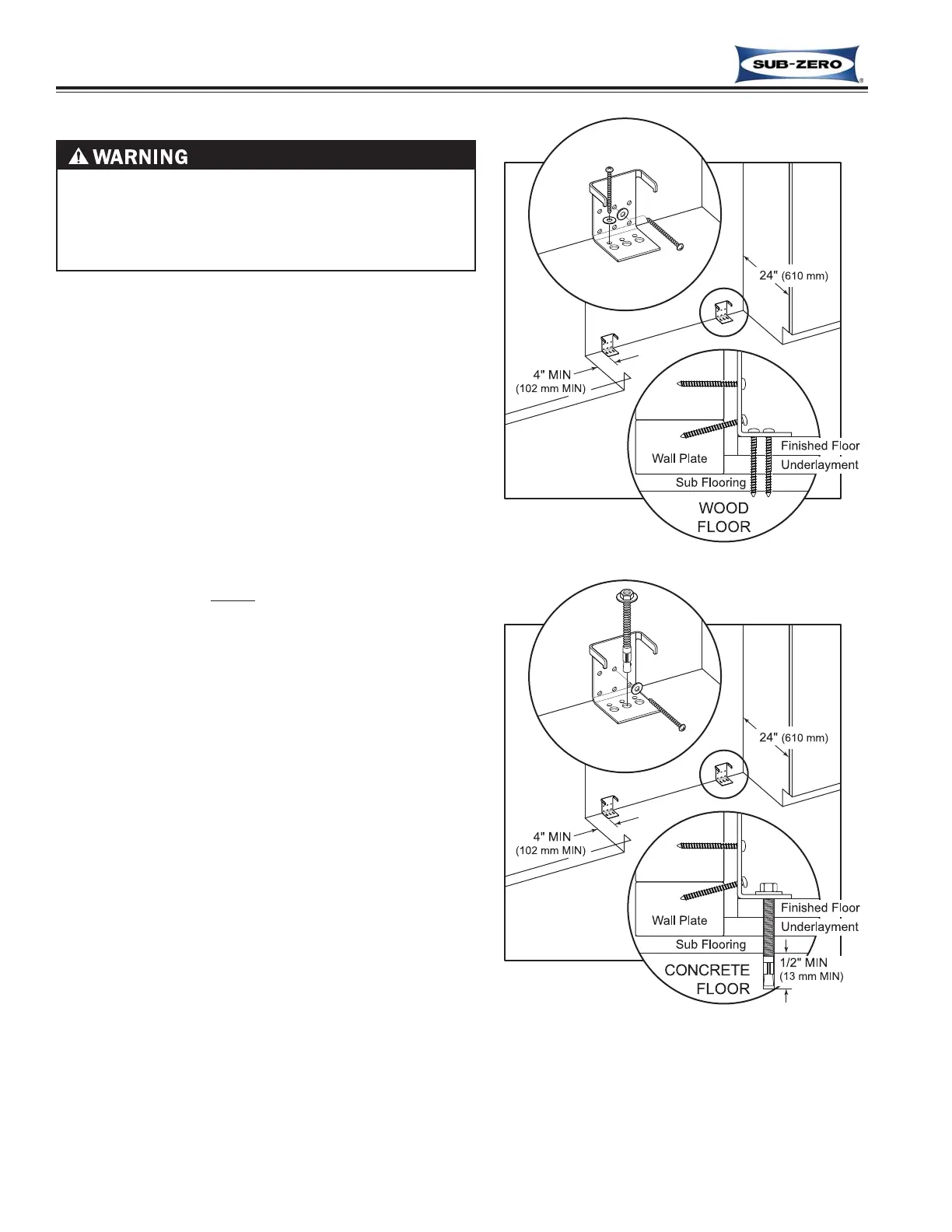

Anti-Tip Bracket Installation

Figure 2-1

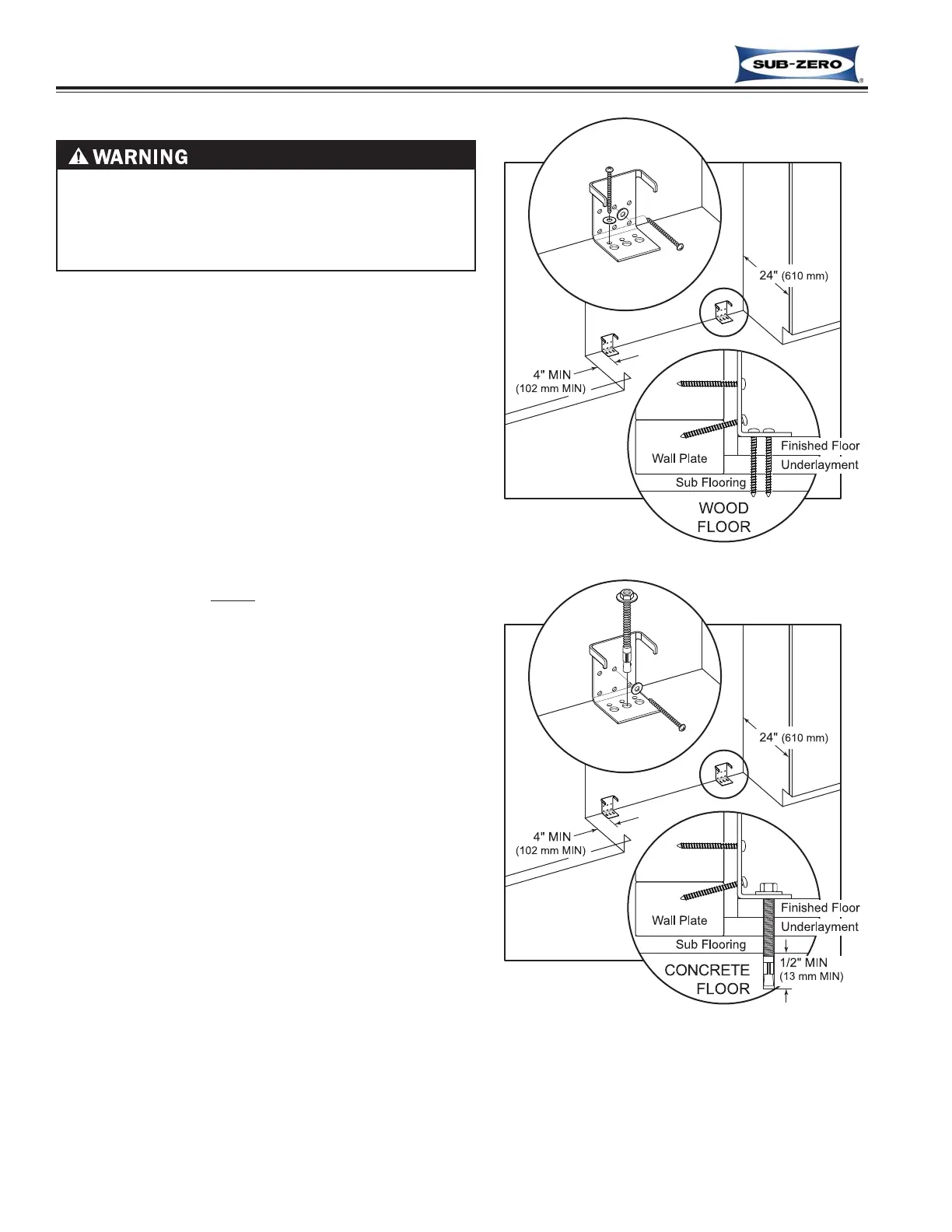

Figure 2-2

THE UNIT COULD TIP FORWARD UNDER CERTAIN

LOAD CONDITIONS. FAILURE TO INSTALL BOTH

ANTI-TIP BRACKETS AND EXTEND LEVELERS TO

FLOOR ACCORDING TO INSTALLATION MANUAL

COULD RESULT IN SERIOUS INJURY OR DEATH.

IMPORTANT NOTE: Placement of the two anti-tip brackets

is critical. They must be installed exactly 24" (610 mm)

from the front of the rough opening to the back of the brack-

ets and a minimum of 4" (102 mm) from the sides of the

rough opening. This depth will increase to 26-3/16" (665

mm) for a flush inset installation based on 3/4" (19 mm)

thick decorative panels. Failure to properly position the

anti-tip brackets will prevent them from engaging the unit

should it tip forward.

Standard Installation Procedure:

The two anti-tip brackets must be located 24''(610 mm)

back from front of rough opening and a minimum of 4” (102

mm) from sides of rough opening. This will ensure that ant-

tip brackets properly engage anti-tip bar at back of unit.

NOTE: Both brackets MUST

be used.

Wood Floor Applications: (See Figure 2-1)

After properly locating anti-tip brackets in rough opening,

drill pilot holes 3/16'' diameter maximum. Then, use the

#12 X 2-1/2” PH Pan HD Zinc Screws and #12 Flat

Washers to secure the brackets in place.

NOTES:

• Make sure screws penetrate flooring material and wall

stud or wall plate a minimum of 3/4'' (19 mm).

• If #12 X 2-1/2'' screws do not hit a wall stud or the wall

plate in any of the brackets back holes, use the #8-18 X

1-1/4” PH Truss HD Screws and #12 Flat Washers with

the Nylon Zip-It Wall Anchors.

Concrete Floor Applications: (See Figure 2-2)

After properly locating anti-tip brackets in rough opening,

drill pilot holes 3/16'' diameter maximum in the wall studs

and/or wall plate, then drill 3/8” diameter holes into the con-

crete a minimum of 1/2“ (13 mm) deep. Then, use the #12

X 2-1/2” PH Pan HD Zinc Screws and #12 Flat Washers to

secure the brackets to the wall, and use the 3/8”-16 X 3-

3/4” Wedge Anchors to secure the brackets to the floor.

NOTES:

• Make sure screws penetrate wall stud or wall plate a

minimum of 3/4'' (19 mm).

• If #12 X 2-1/2'' screws do not hit a wall stud or the wall

plate in any of the brackets back holes, use the#8-18 X

1-1/4” PH Truss HD Screws and #12 Flat Washers with

the Nylon Zip-It Wall Anchors.

Loading...

Loading...