FILTERS AND MOISTURE SEPARATORS SECTION 2

12

2.3 UNPACKING

Handle carefully. Check the packing list to account

for all items. Visually inspect for shipping damage. If

damaged, immediately file a claim with the carrier.

2.4 ELEMENT FEATURES

• 7 element types (see Table 2-1 below)

• Superior construction

• Efficient drainage layer

• Hydrophobic Microglass Fiber

• Deep pleats (for reverse flow elements)

• Stainless steel cores

• Special disruptive pattern

• PVC impregnated layer (for coalescers)

• End cap key fit

• Individually boxed

• Color coded elements for easy

identification

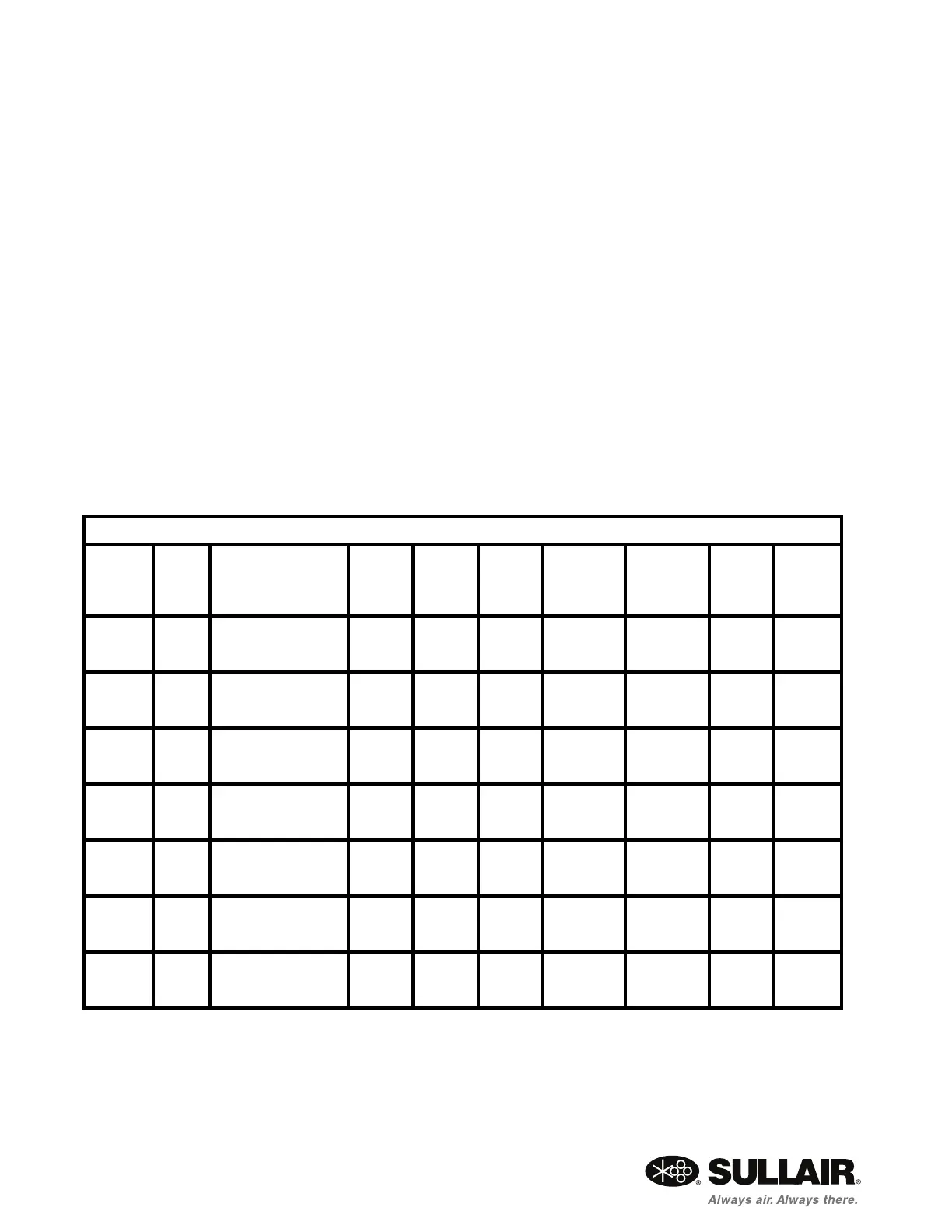

Table 2-1: Element Specifications

SULLAIR

ELEMENT

TYPE

COLOR

CODE

Efficiency &

Coalescer

Performance

Media/

Type/

Pattern

Flow

Direction

Max

Operating

Pressure

Max Operating

Temperature

Min Operating

Temperature

Dry

Pressure

drop (psig)

Wet

Pressure

Drop (psig)

FBLUE

1 MICRON &

.5 ppm Carryover

Wrapped In-to-Out 285 PSI 176° F 36° F 0.6 1.2

FR WHITE

REVERSE 1 MICRON

& .5 ppm Carryover

Pleated Out-to-In 285 PSI 176° F 36° F 0.35 0.6

FRHT METAL

REVERSE 1 MICRON

& .5 ppm Carryover

HIGH

TEMP/

Pleated

Out-to-In 285 PSI 350° F 36° F 0.35 0.6

HRED

0.01 MICRON

& .01 ppm Carryover

Wrapped In-to-Out 285 PSI 176° F 36° F 1.2 2.3

HR WHITE

REVERSE

0.01 MICRON

& .01 ppm Carryover

Pleated Out-to-In 285 PSI 176° F 36° F 0.45 0.7

C¹ METAL

0.01 MICRON

& .003 ppm Carryover

Granular

Activated

Carbon

Out-to-In 285 PSI 122° F 36° F 2.3 -

U (Ultra) WHITE 0.01 MICRON Absolute Wrapped Out-to-in 285 PSI 176° F 36° F 5-

1-Precede C Type filters with HR Type Filters / Change C Type element at 6000 hours or when oil vapor odor detected.

Grade A metal odor removal not to be used in oil-saturated conditions.

Loading...

Loading...