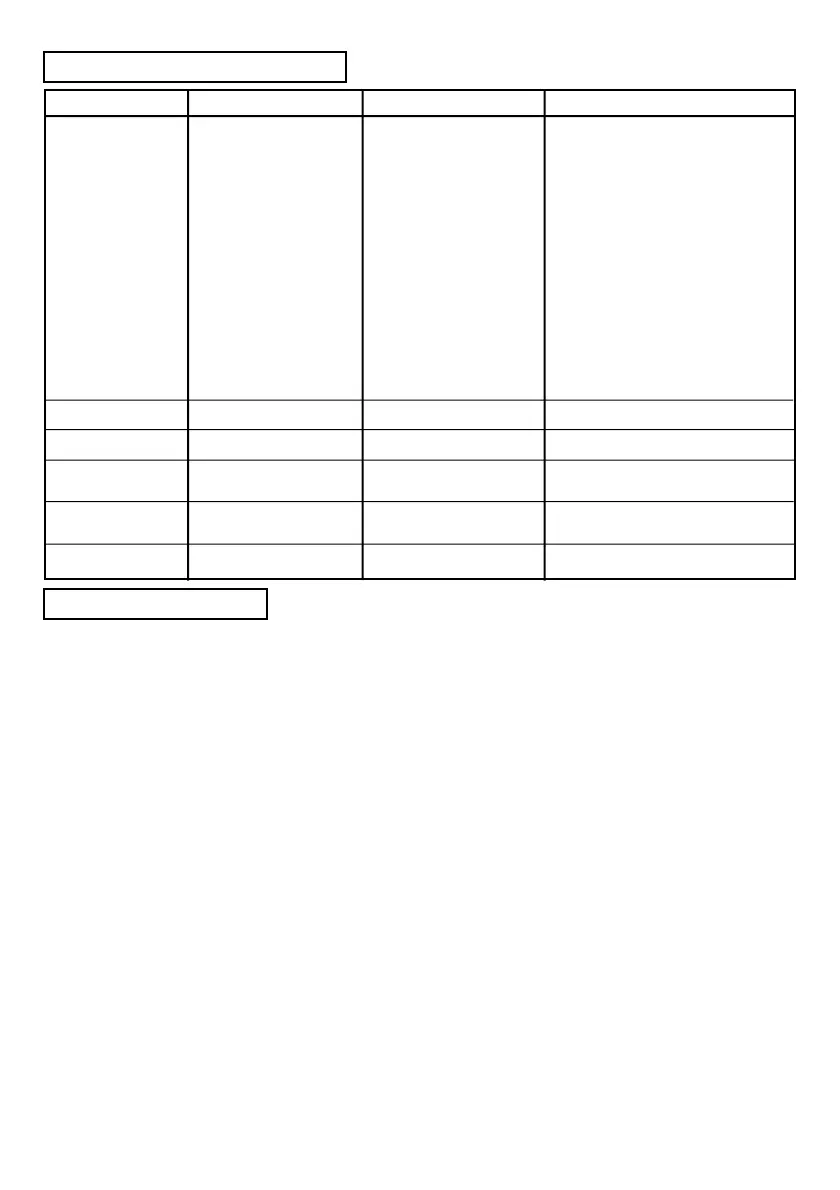

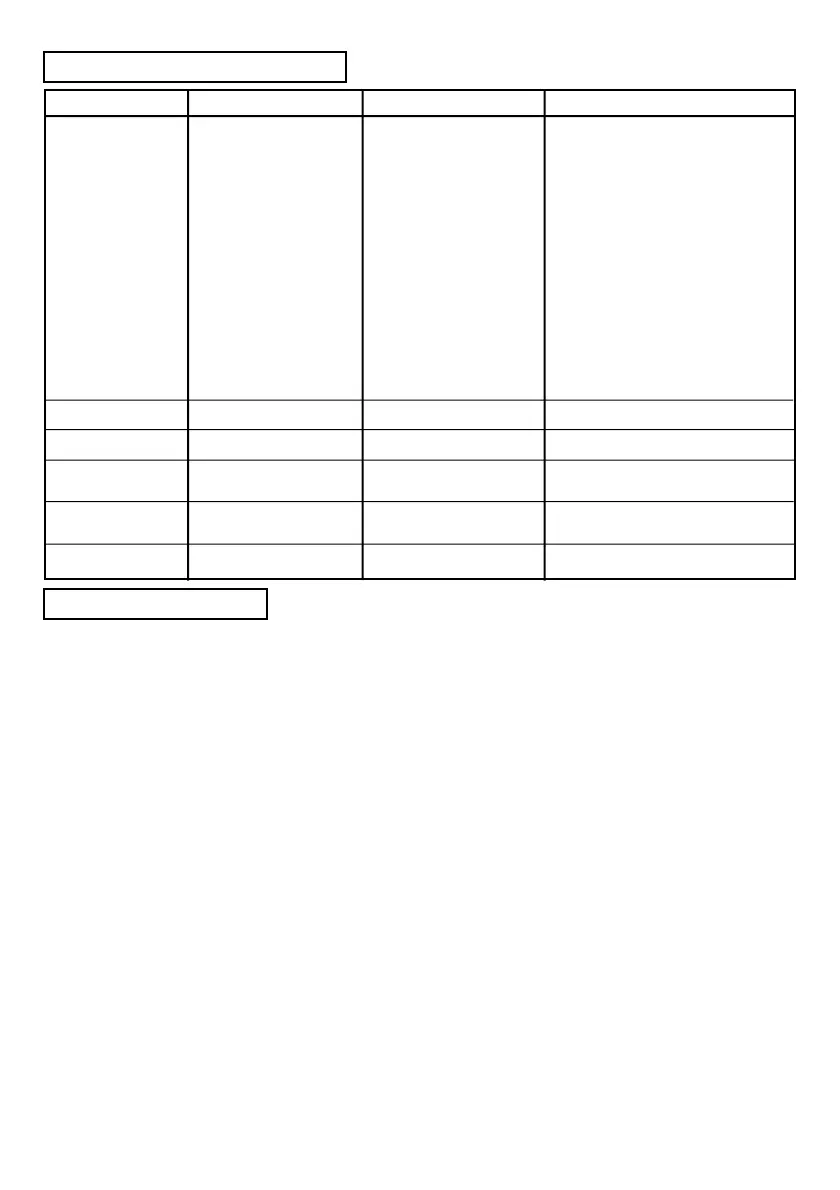

Problem Indication Probable cause Remedy

Poor Dewpoint Crystals go pink in outlet Entrained water Check pre-filtration and pre-filtration drains

moisture indicator

Excessive air flow demand Check actual flow against rated flow of dryer

Check for recent additions to air system

Inlet pressure too low Check against technical specification

Excessive inlet air temperature Check against technical specification

Insufficient purge air flow Factory set for 6 bar g (87 psig) system

pressure.

Sullair trained personnel to adjust

Exhaust silencers blocked Change by Sullair trained personnel

Contaminated desiccant Eliminate source of contamination. Desiccant

change by Sullair trained personnel

Electrical fault Flashing Yellow LED Hardware fault Contact Sullair customer services

High differential pressure Pressure gauges Excessive outlet flow Check and regulate air demand

Failure to purge No depressurisation Purge valve blocked or shut. Sullair trained personnel to adjust

and poor dewpoint Exhaust silencers blocked Change by Sullair trained personnel

Outlet air flow stops Downstream pressure drops Electrical fault Contact Sullair customer services

Yellow LED “OFF” Blown fuse in plug Change by competent personnel

Constant depressurisationErratic air flow from exhaust Damaged valve Change by Sullair trained personnel

7

8. FAULT DIAGNOSIS TABLE

Filters

Lack of filtration.

Installation of inlet filters remote from the dryer inlet head, allowing possible condensation to occur

between filters and dryer.

Blow down valve upstream of filters causing back flow / possible collapse of filter element.

Installing filters in wrong flow direction.

Opening inlet valve too quickly, causing initial high differential pressure across filter element.

Differential pressure gauge/indicator fitted wrong way around giving false differential pressure reading.

Combining drain pipes from filters to a single drain valve.

Inlet / outlet head

Pipe diameter too small.

Pipework unsupported.

Inlet pipework taken from low point of manifold range, allowing bulk water intrusion into the dryer.

Control box/electric’s

Incorrect wiring configuration by user, or incorrect supply voltage.

No neutral or earth wire fitted by user to dryer.

Additional Items

Use of non recommended componentry.

Untrained / unauthorised maintenance or installation personnel used.

Subsequent increase in air consumption without relation to dryer flow capacity.

Purging of pneumatic system and dryer with cleaning agents that have the potential to damage desiccant

material.

Covers removed or loose during operation.

9. KNOWN MISUSE

Loading...

Loading...