INSTALLATION, START-UP & MAINTENANCE MANUAL

SD-220 TO SD-600

REV 04 – 10 Oct 2003

Page 7 of 32

1.4. PRODUCT INFORMATION

The adsorption dryer is used for the purpose of drying compressed air and other gases

according to its respective design. As a "standard model" the adsorption dryer is equipped

with two desiccant vessels, a pre filter and an after filter, and depending on certain

conditions at the outlet, provides pure, dry and oil-free compressed air or gas.

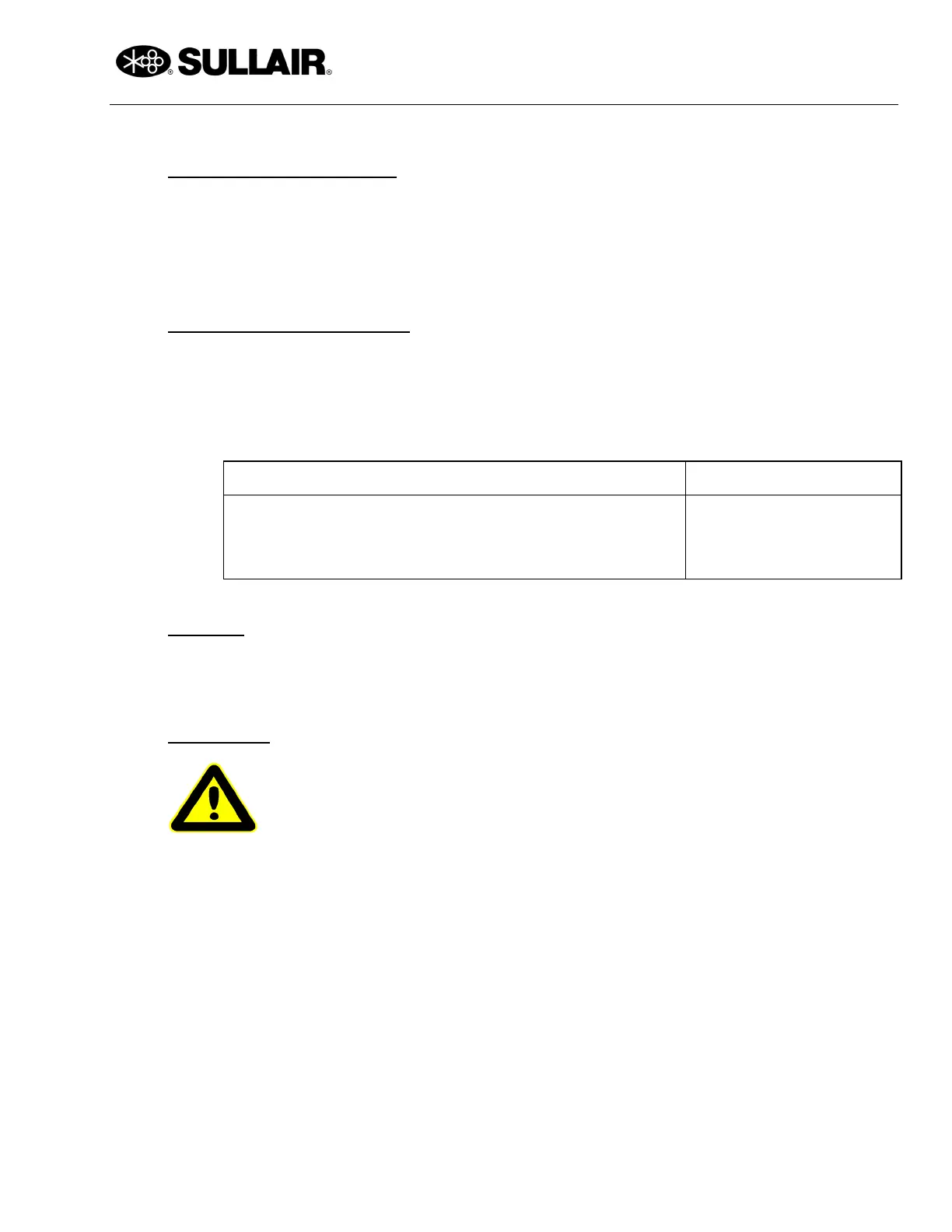

1.4.1. Pressure Vessel Regulations

The pressure vessels are designed according to the standard technical requirements.

They fulfill the test of the certifying procedure and carry the “U”, “UM” ASME Symbol.

Range of application

Maximum Design Pressure 150 PSIG

Maximum Temperature

Minimum Temperature

500 °F

-20 °F

1.4.2. Leak test

Prior to shipment, all adsorption dryers are subjected to a comprehensive leak test

using compressed air.

1.4.3. Overloading

CAUTION!

Protect the adsorption dryer from overloading!

The adsorption dryer can become overloaded, if:

• The flow capacity of the medium to be dried increases,

• The temperature of the air at entry, and it’s corresponding humidity

increases,

• The minimum operating pressure decreases,

• The pre filtration and separation of impurities are not sufficient, or the

filter drain fails.

Loading...

Loading...