2.5

SECTION 2 - SPRAYER OPERATION

8. ADJUSTMENT TO LEVEL SPRAYER BOOMS

A. Park sprayer on a level surface.

B. Level swinging center with a jack or blocks.

C. Check level of each inner boom.

Level adjustment is performed near tiplift cylinder on top of inner boom.

1. To adjust loosen jam nut near tiplift cylinder.

2. Adjust 1-1/2” bolt in or out until boom is level with swinging center.

3. Tighten jam nut to secure adjustment

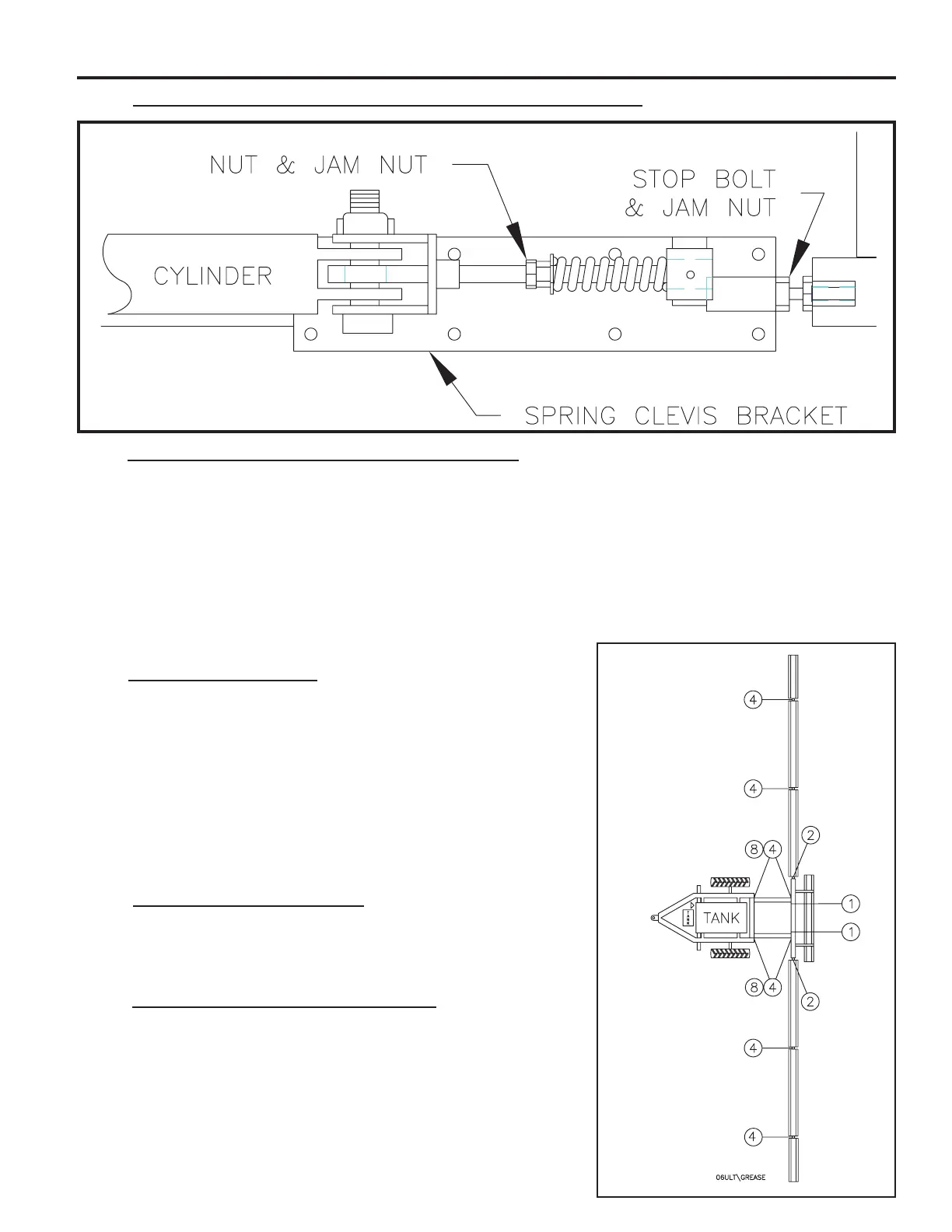

9. CHECK BOOM LEAD

A. With booms unfolded; manually force booms rearward

to collapse spring clevis on inner boom fold cylinders.

Booms should not move rearward past a line extending

straight out from sprayer boom swinging center.

B. Perform any required adjustment at the part 1 boom fold

cylinder eyebolt.

C. Verify both nuts are tight to secure the adjustment.

10. CHECK TIRE PRESSURES

See specications page 7.2 for proper tire ination pres-

sures. Maximum pressures are stamped on tire.

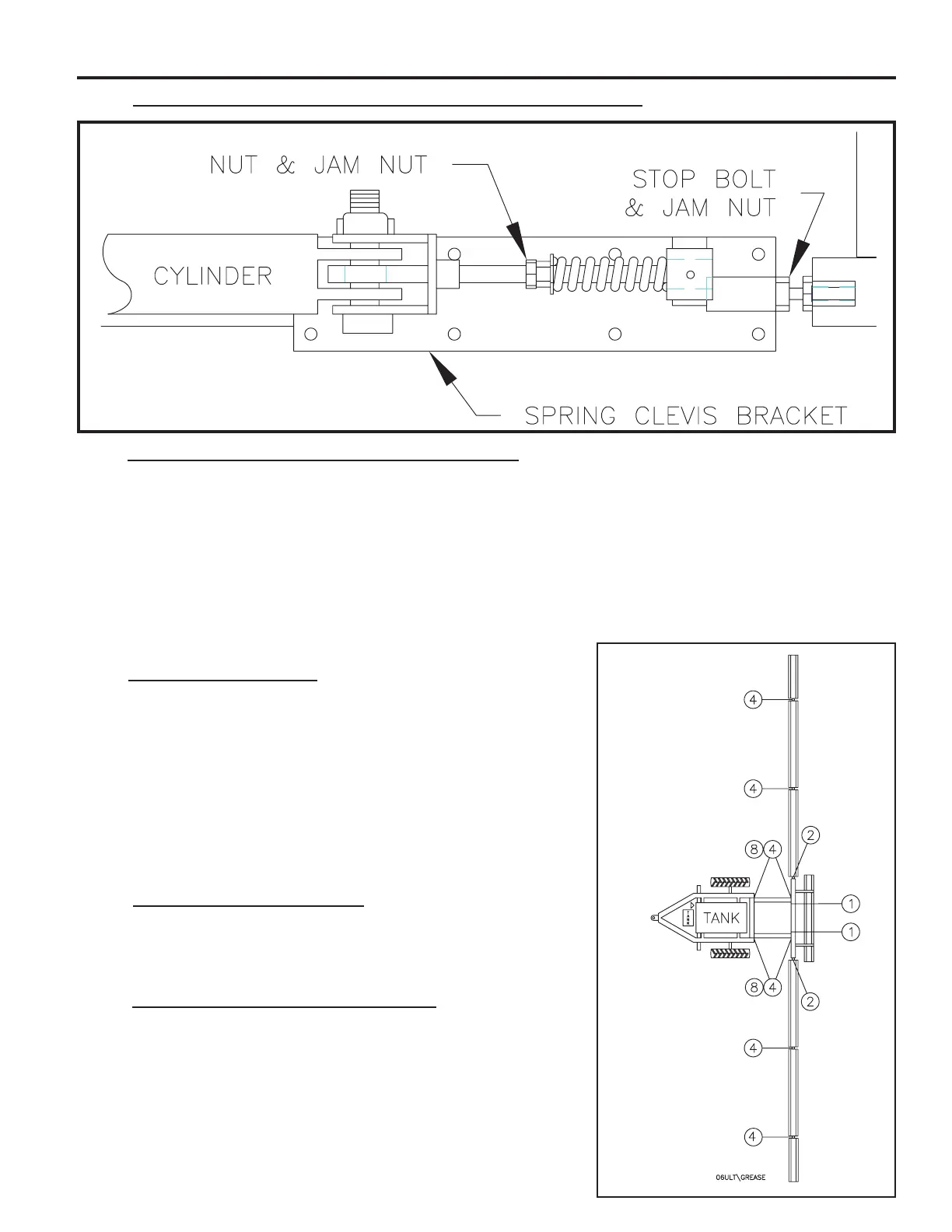

11. PERFORM DAILY MAINTENANCE

A. Grease all points shown (See gure 2).

B. Verify all wheel bolts are tight.

C. Check hydraulic components for leaks or frayed hoses.

D. Inspect plumbing for leaks and problem areas.

E. Perform general inspection for loose or missing parts.

Figure 2

7. INNER BOOM CYLINDER SPRING CLEVIS ADJUSTMENT

Loading...

Loading...