2.22

SECTION 2 - SPRAYER OPERATION

10. PERFORM SPRAYER SYSTEM DAILY MAINTENANCE

A. Check all sprayer system components for leaks.

B. Clean sprayer system strainer.

C. Check water level in safety water tank plus check that rubber gloves and goggles are present.

D. Check tanks for movement and tighten hold down components as required.

E. Check nozzle patterns. If a nozzle pattern is distorted:

1. Remove nozzle tip.

2. Clean with toothbrush, wooden or plastic probe. Never use a metal object since damage will

occur.

3. Blow out nozzle tip with compressed air no greater than 40 psi. Never use your mouth to

blow out a nozzle tip.

4. Replace nozzle tip if necessary.

5. Install nozzle tip back onto sprayer.

F. During periods of use in freezing temperatures:

1. Flush entire sprayer system with recreational vehicle (RV) anti-freeze. RV anti-freeze is non-

toxic and safe for the environment. It must be used in 100 % concentrations, but it is more

economical than permanent anti-freeze to purchase and will not corrode plastic sprayer com-

4. Close hopper lid and lock by turning clockwise.

5. Divert pump discharge ow back to normal operation by closing valves “C” or “P”.

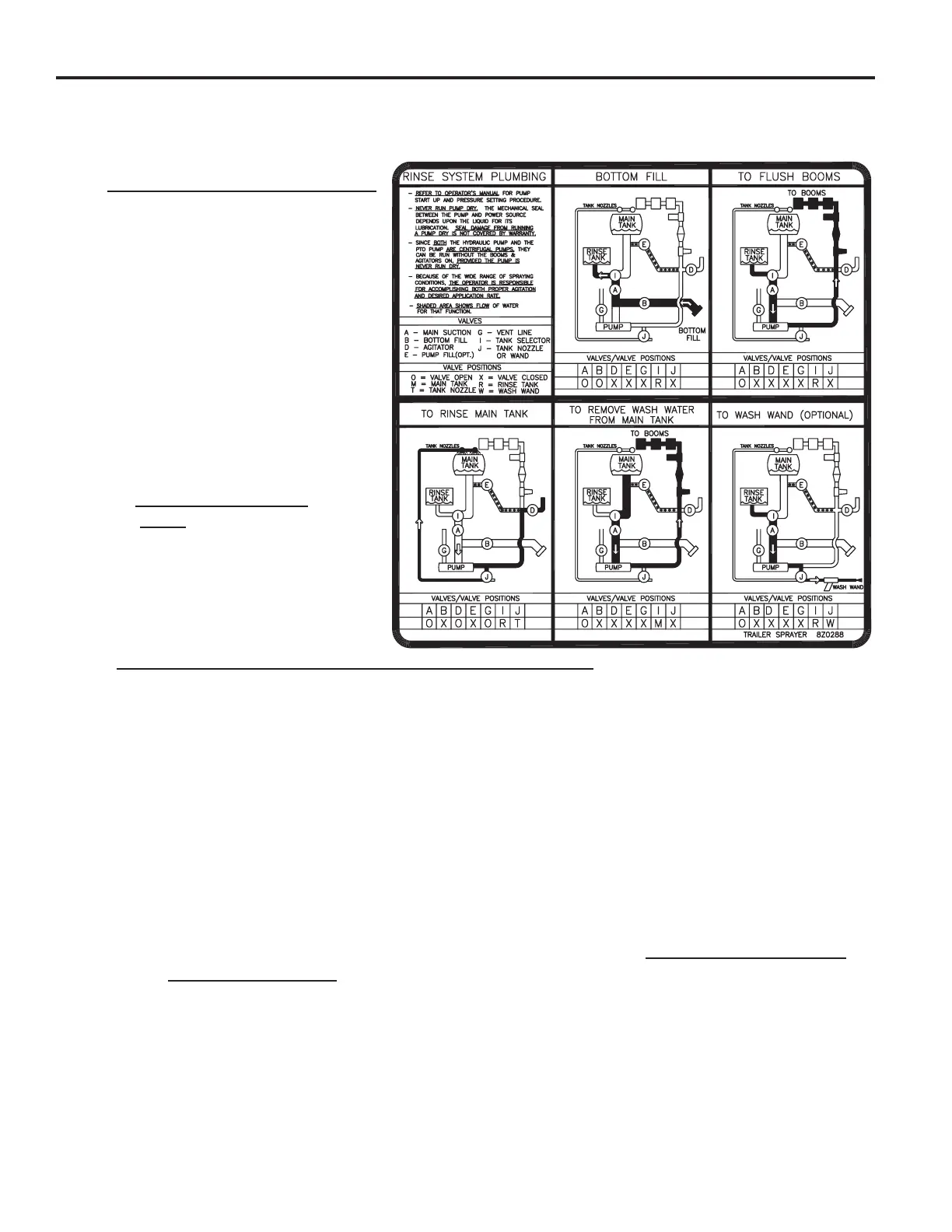

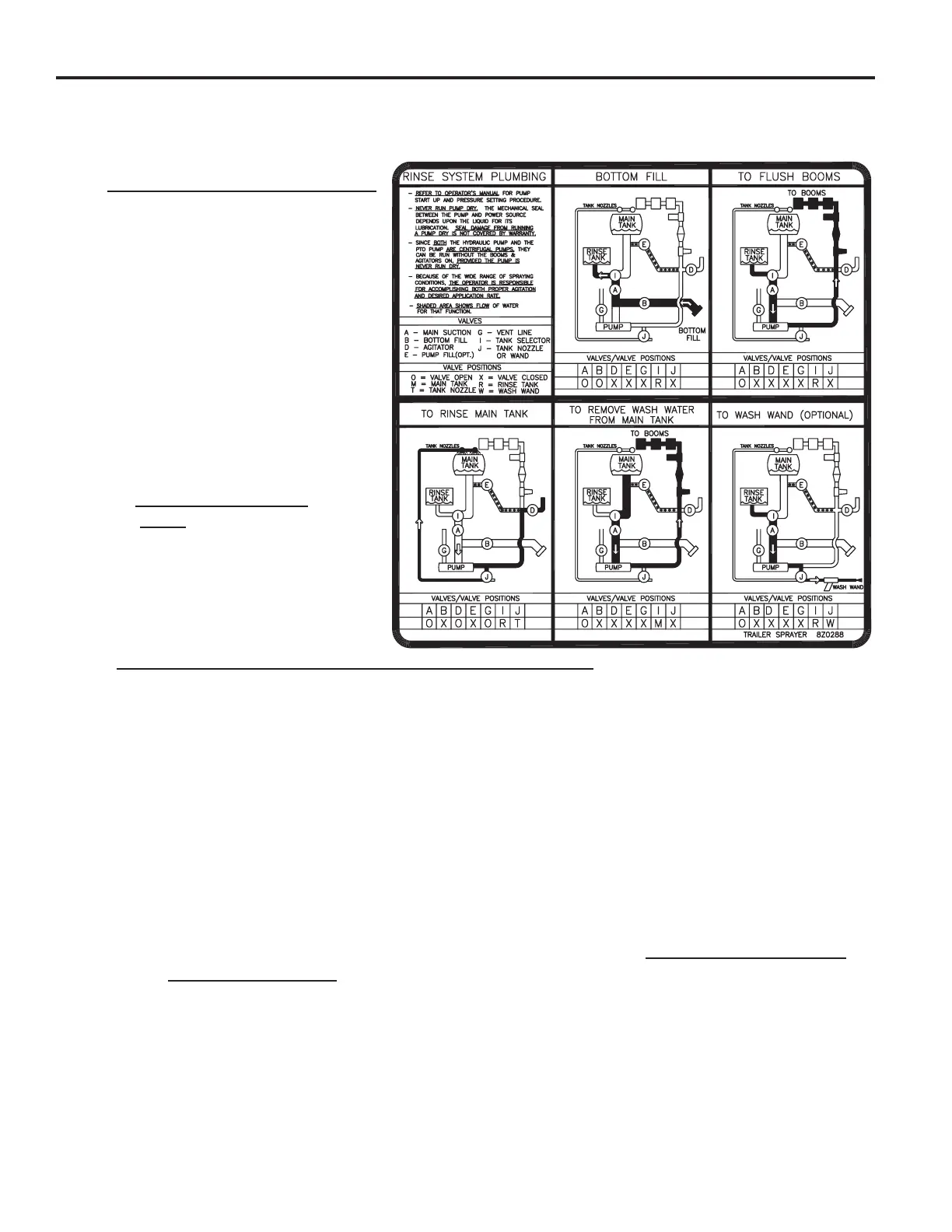

9. TEST OPTIONAL RINSE TANK

A. Add approximately 40

gallons of water to RINSE

TANK using Bottom Fill or

through top llwell.

B. Set up and test all functions

of RINSE TANK individu-

ally.

1. Position valves as shown for

each operation.

2. Engage tractor hydraulic

system or PTO system.

3. NEVER RUN PUMP

DRY! Check that rinse op-

eration is running correctly.

4. Disengage sprayer pump.

5. Reposition valves for next

spray operation.

Loading...

Loading...