2.21

SECTION 2 - SPRAYER OPERATION

D. Disengage tractor hydraulic system or PTO system.

E. Close all valves.

8. TEST OPTIONAL CLEAN LOAD SYSTEM

LOADING

1. All Cleanload valves must be closed prior to starting. Inlet ball valve, knife valve, and hopper rinse

ball valve.

2. Open lid to check for foreign objects which may hinder performance or contaminate the system.

3. Close and lock lid by turning cover clockwise.

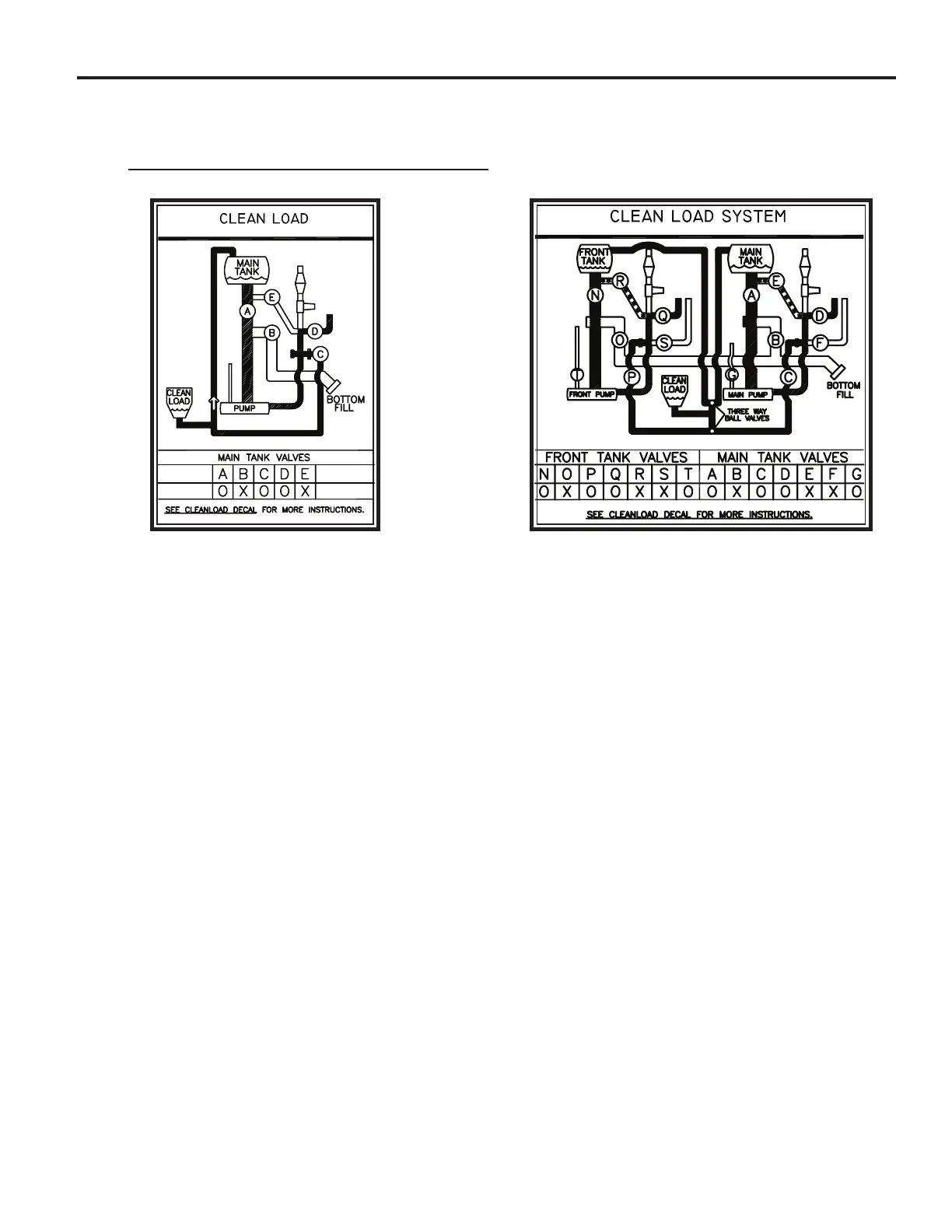

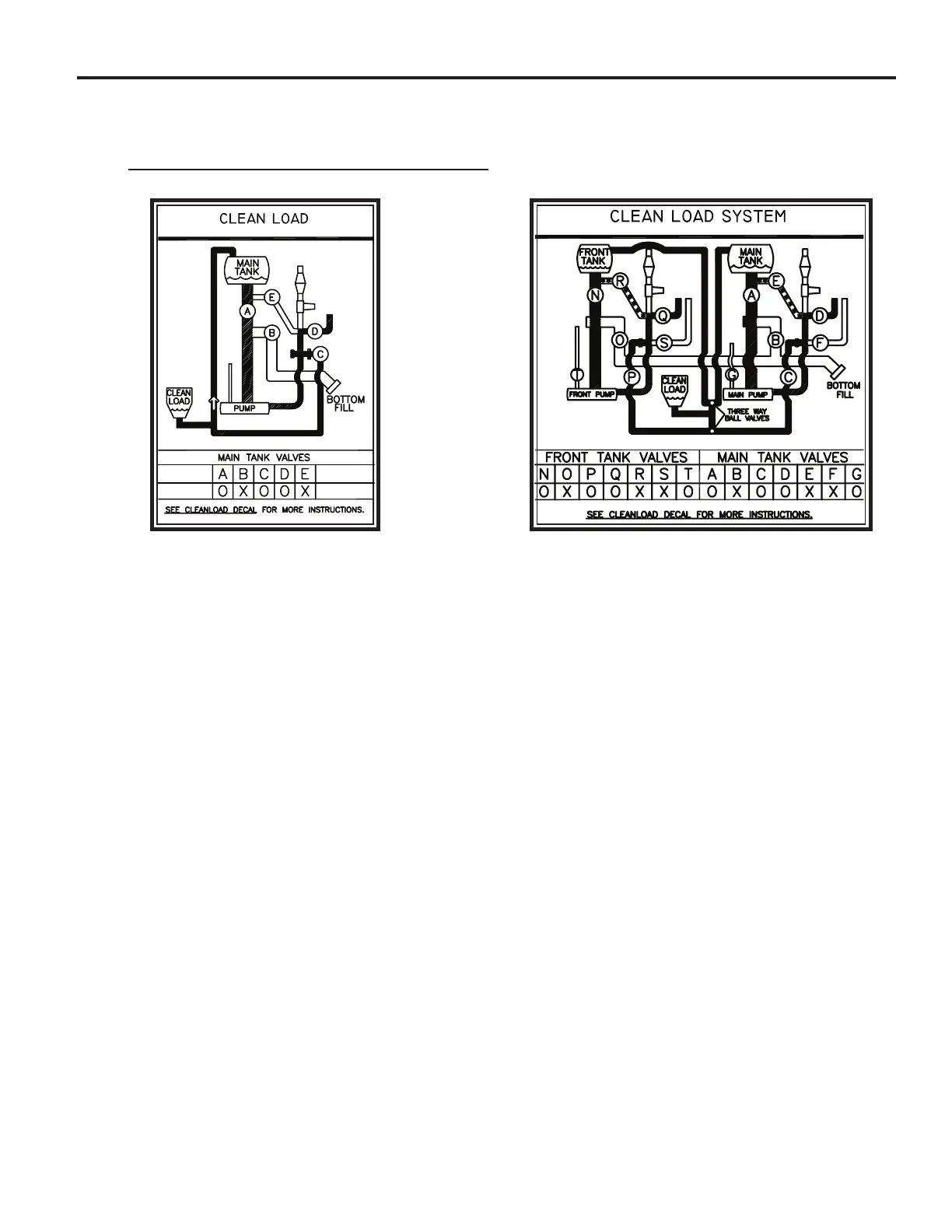

4. Divert pump ow to cleanload inlet line (open valves “C” or “P”). A pressure of 30 PSI minimum

and 150 PSI maximum must be used. Highest pressures increase the education rate and available

wand suction.

5. Open knife valve located on the bottom of hopper by pushing handle in.

6. Unlock and open lid slowly by turning cover counterclockwise.

LOADING LIQUID OR POWDERED CHEMICAL INTO HOPPER

7. Pour required amount of chemical into hopper. Avoid splashing liquids or powdered chemicals

outside of hopper.

8. Rinse empty chemical containers if applicable. Place container opening over container rinse valve

and press down. This will activate the rinse valve and rinse container.

9. Rinse cleanload hopper. Close and lock lid by turning cover clockwise. Release the safety lock-

ing band on the hopper rinse ball valve and turn on for 20 seconds. Close ball valve and return

locking band to locked position.

10. Open lid and inspect for chemical residue. Repeat step 10 as necessary.

11. Close knife valve by pulling red handle out towards you. Turn inlet valve off.

SHUTDOWN

1. Close knife valve rst by pulling red handle out towards you.

2. Insure that the remaining valves are closed.

3. Verify chemical residue has been cleaned up.

Loading...

Loading...