18

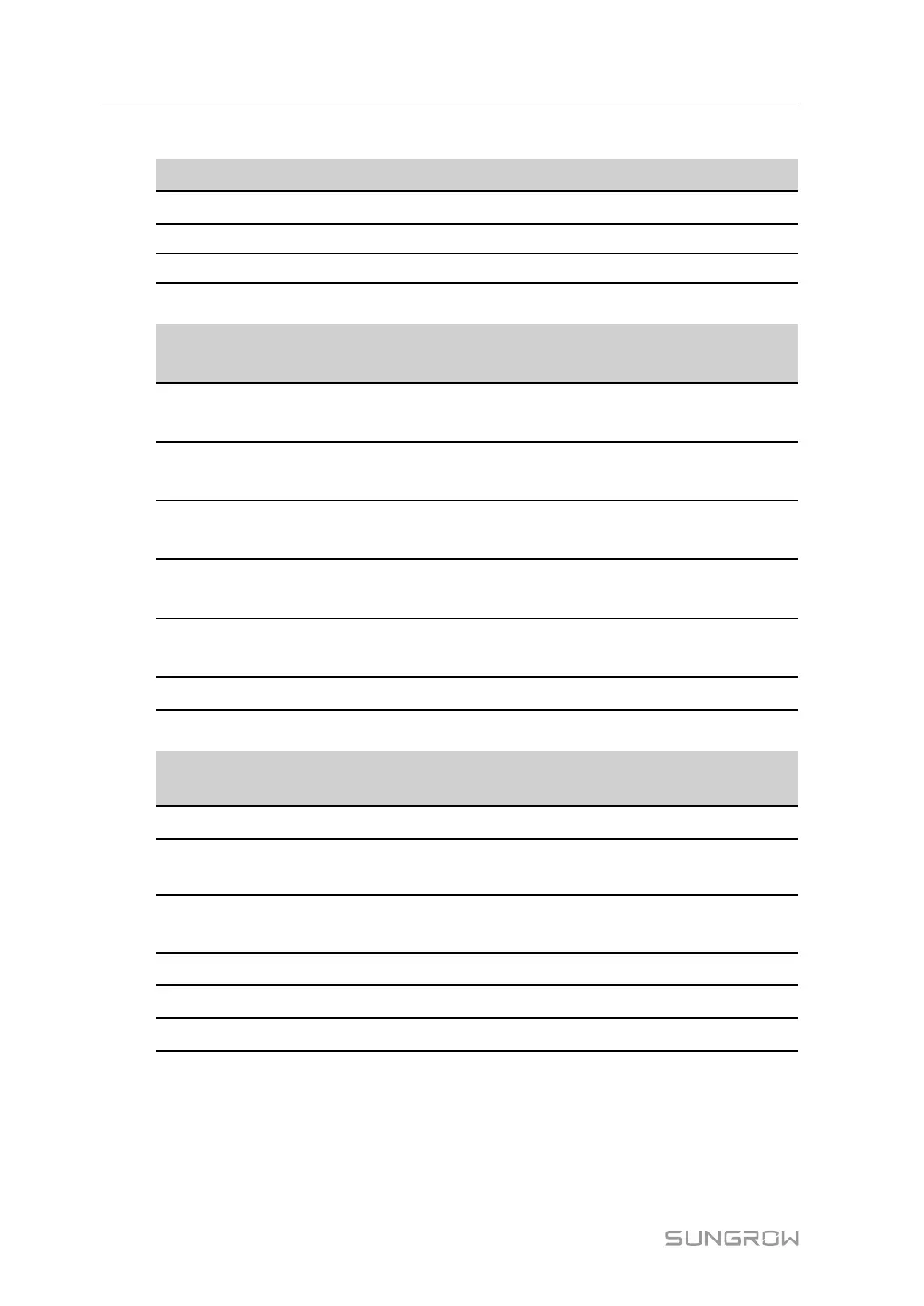

Torque guidelines for external cabinet fasteners

Fasten torque Nominal Torque(In-Ibs) Torque Range(In-Ibs)

Penta-head security bolt

100 80-120

3/8’’ bolt 550 500-600

Hand-hole cover bolt 150 170-210

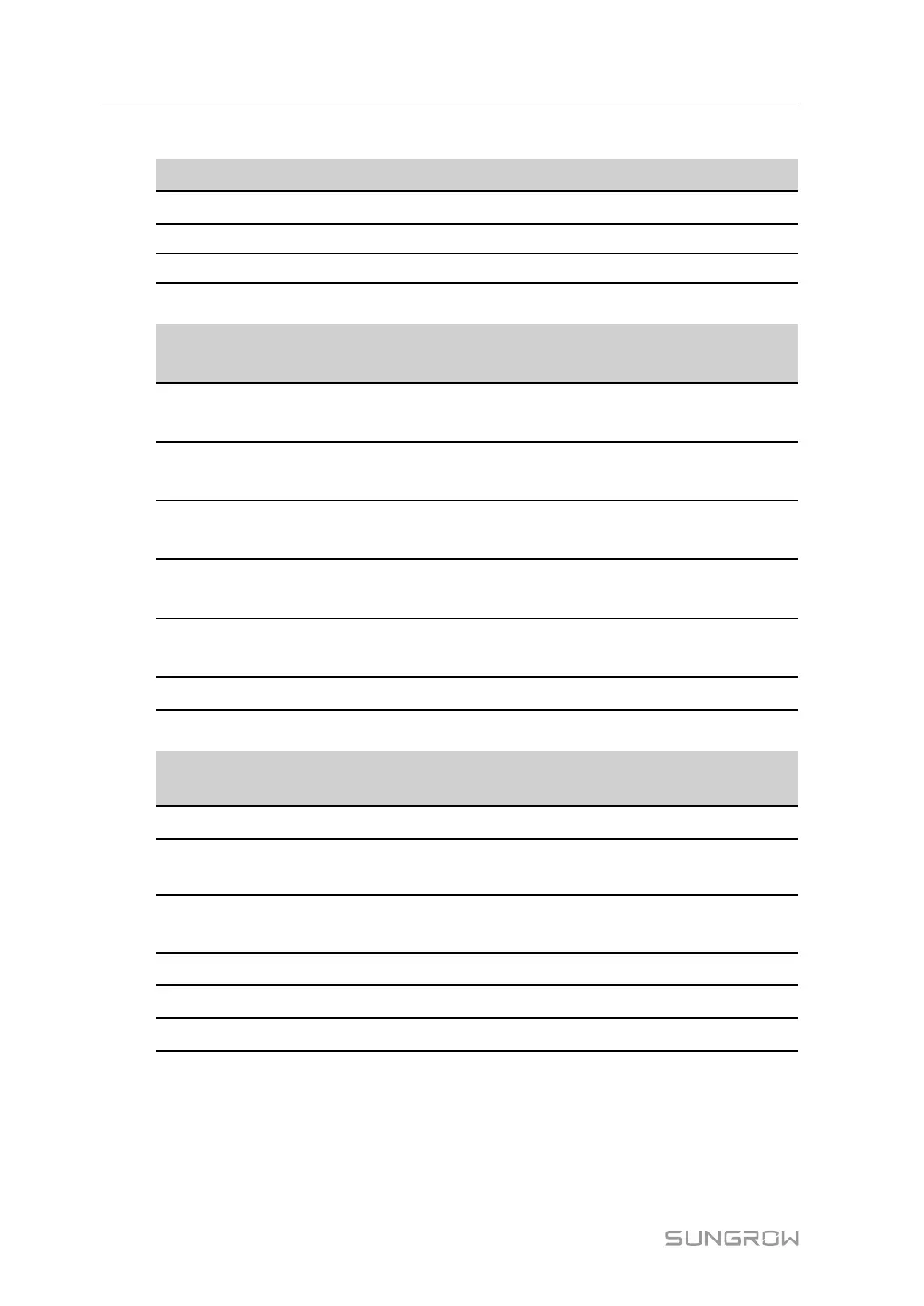

Torque guidelines for external bushings mounting hardware

Fasten torque Nominal Torque

(In-Ibs)

Torque Range

(In-Ibs)

Low-voltage bushing, molded tri-clamp(without

clamp ring), 3/8’’ mounting studs

60 40-80

Low-voltage bushing, molded tri-clamp(with clamp

ring), 3/8’’ mounting studs

120 90-150

Low-voltage bushing, porcelain (with clamp ring),

1/2’’ mounting studs

80 70-90

High-voltage bushing, molded tri-clamp (without

clamp ring), 3/8’’ mounting studs

60 40-80

High-voltage bushing, molded (with clamp ring), 3/

8’’ mounting studs

120 90-150

High-voltage bushing, porcelain

80 70-90

Torque guidelines for external bushing terminal connections

Terminal type Nominal Torque(In-Ibs)

**

Torque Range(In-Ibs)

High-voltage molded bushing insert*

180 170-190

High-voltage porcelain bushing eye-

bolt

210 180-240

High-voltage porcelain bushing end

cap

168 156-180

Low-voltage bushing, 5/8’’ jam nut

600 480-720

Low-voltage bushing, 1’’ jam nut

600 480-720

Low-voltage bushing, 1-1/4’’ jam nut

720 600-840

*Apply silicone grease before installation according to the insert manufacturer’s instructions.

**When checking tightness of gasketed components, the measured torque will normally be

less than the nominal torque listed in the table above due to relaxation of the gasket material.

Additional tightening of bushing mounting hardware may cause the component to crack or

the gasket to become over-compressed.

7 Service Preparation User Manual

Loading...

Loading...