19

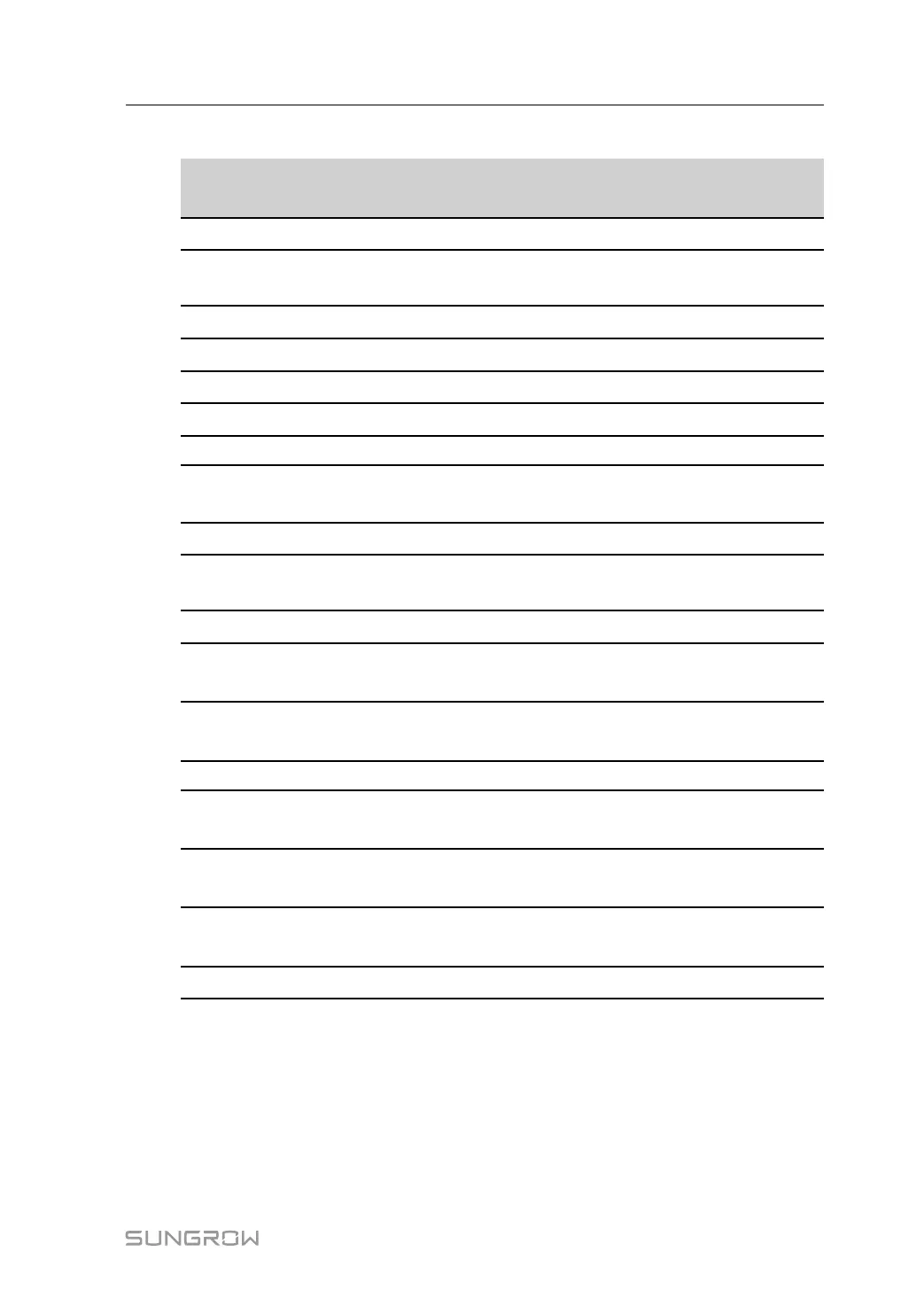

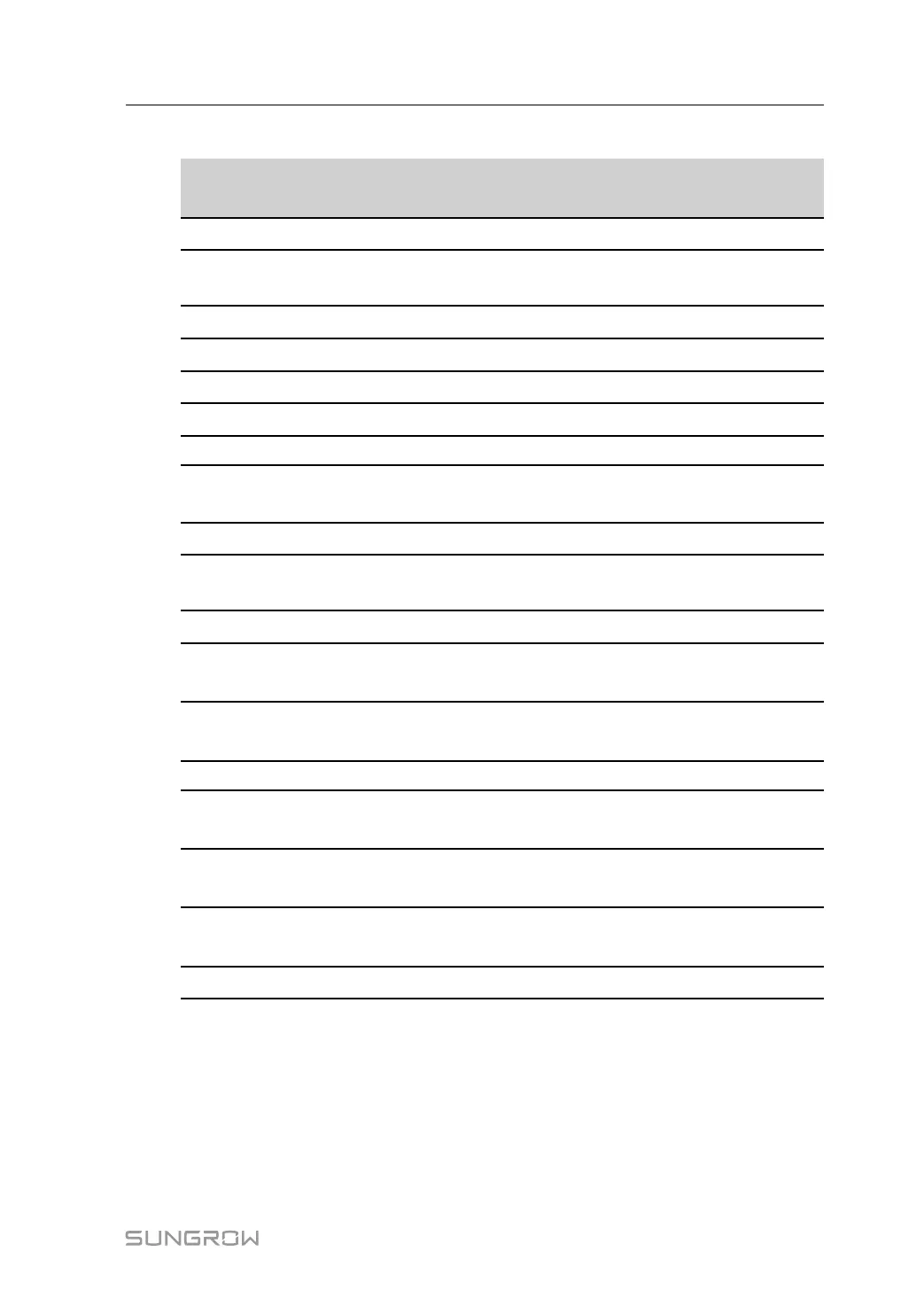

Torque guidelines for accessories

Component Nominal Torque(In-

Ibs)*

Torque Range(In-

Ibs)

Bay-O-Net fuse cartridge end plug

70 60-80

Bay-O-Net fuse holder-to-cartridge

connection

70 60-80

Dry-well fuse canister clamp

60 40-80

Fluid-level sight plug

600 480-720

Fill plug

960 900-1020

Drain plug

960 900-1020

Drain valve 600 480-720

Automatic pressure relief device, panel-

mounted, 1/4” NPT

180 160-200

Automatic pressure relief valve, 1/2” NPT

180 170-190

Automatic pressure relief device, cover-

mounted

300 250-350

Neutral strap fastener (at ground pad)

160 140-180

Series/multiple, delta/wye or tap switch

mounting nut

120 96-144

MOV arrester disconnector mounting nut

(ECI brand)

120 96-144

Ground connector 160 140-180

Rotary load-break switch (Central Moloney

brand)

1200 1100-1300

Rotary load-break switch (Cooper Power

brand)

600 480-720

Rotary load-break switch handle (Allen

screw)

55 45-65

High voltage cable clamp

160 140-180

* When checking tightness of gasketed components, the measured torque will normally be

less than the nominal torque listed in the table above due to relaxation of the gasket material.

Additional tightening of bushing mounting hardware may cause the component to crack or

the gasket to become over-compressed.

User Manual 7 Service Preparation

Loading...

Loading...