28

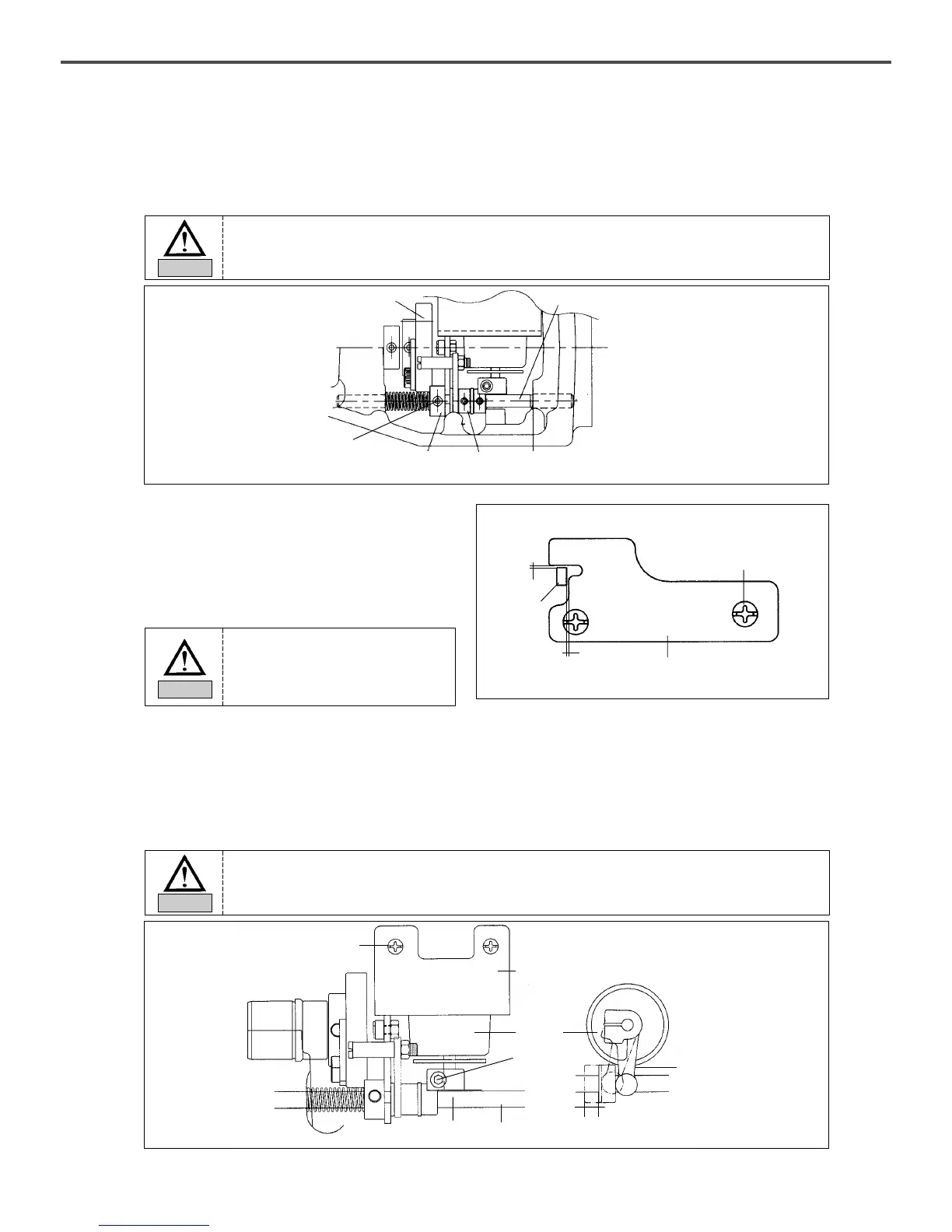

C. Setting the trimming shaft in place

ⓐ Unfasten the trimming drive link screw and the trimming shaft collar screw.

ⓑ Make the trimming shaft step accord with part of the arm.

ⓒ Tighten the screws.

[ Fig. 51 ]

Thread Trimmer Shaft

Thread Trimmer Cam

Screw

Thread Trimming

Driving Link

Collar for

Thread Trimmer Shaft

D. Setting the Link Stopper in Place

ⓐ Unfasten the trimming drive link stopper

screw while trimming is not operated and

have the trimming drive link and the

trimming drive link stopper notch 0.3mm

apart from each other.

ⓑ Tighten the screw.

[ Fig. 52 ]

→

→

0.3mm

Thread

Trimmer

Driving

Link

Screw

Thread Trimmer Driving

Link Stopper

→

→

0.3mm

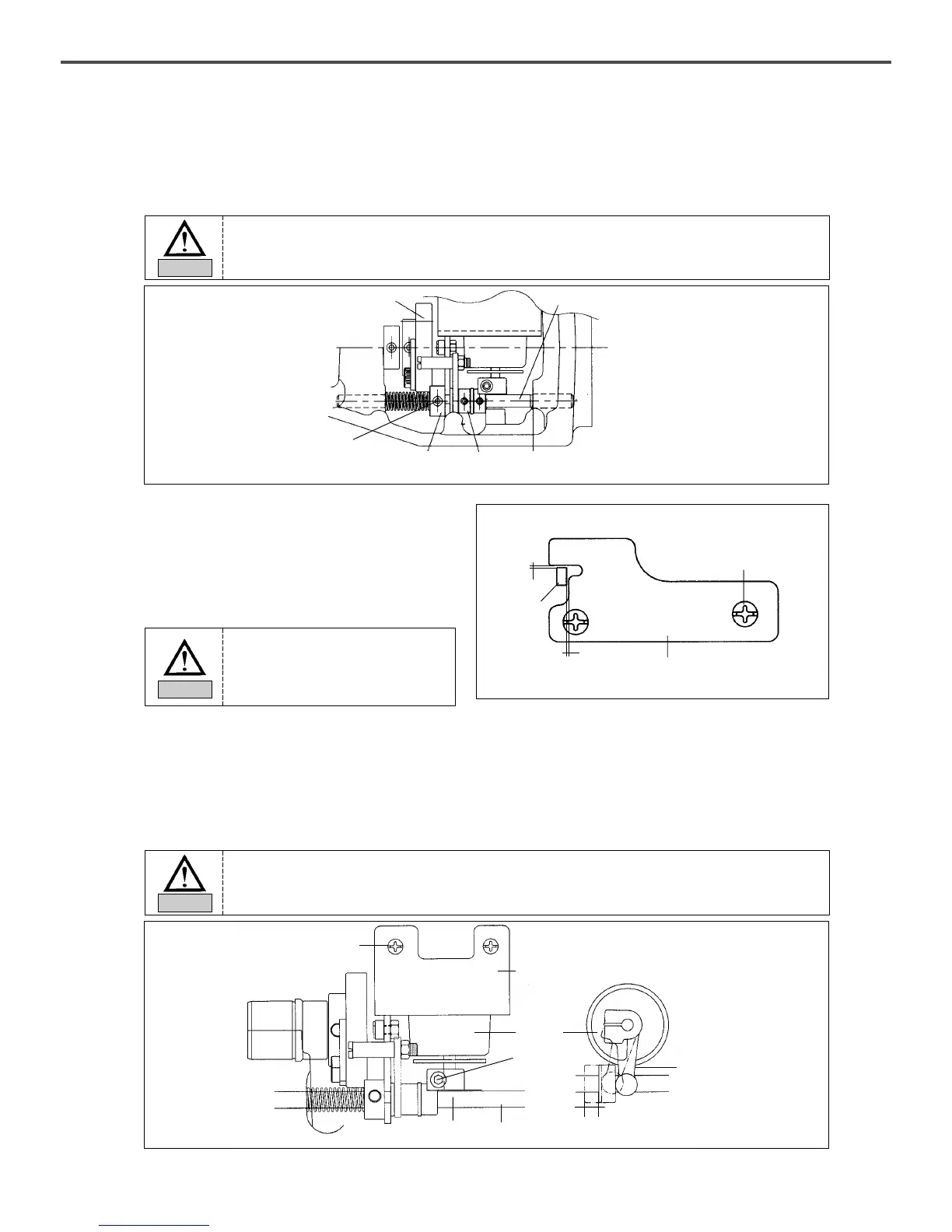

E. Setting the Thread Trimming Solenoid in Place

ⓐ After unfastening the thread trimming solenoid bracket screw, have the trimming shaft and the thread

trimming solenoid rotary link 0.5mm apart from each other and tighten the screw back on.

ⓑ Unfasten the thread trimming solenoid rotary link screw and drive the thread trimming solenoid rotary

link manually to move the trimming shaft collar 6.8mm in the direction of the arrow. Then, tighten the

screw back on.

ⓒ Check if the trimming shaft collar returns to its place when the thread trimming solenoid rotary

link returns.

[ Fig. 53 ]

→

→

0.5mm

Solenoid

Thread

Trimming

Rotation Link

Thread Trimmer Solenoid Bracket

Screw

Screw

Thread Trimmer Shaft

Thread Trimming Rotation Link

6.8mm

→

→

If the position is not adjusted appropriately, trimming may not be operated correctly or

the machine may be lock.

Caution

If the position is not set right, the trimming return or the thread delay may be delayed to bring poor

sewing quality.

Caution

If the link stopper is not set in the

right position, trimming may not be

operated correctly and the machine

may be lock.

Caution

Loading...

Loading...