25

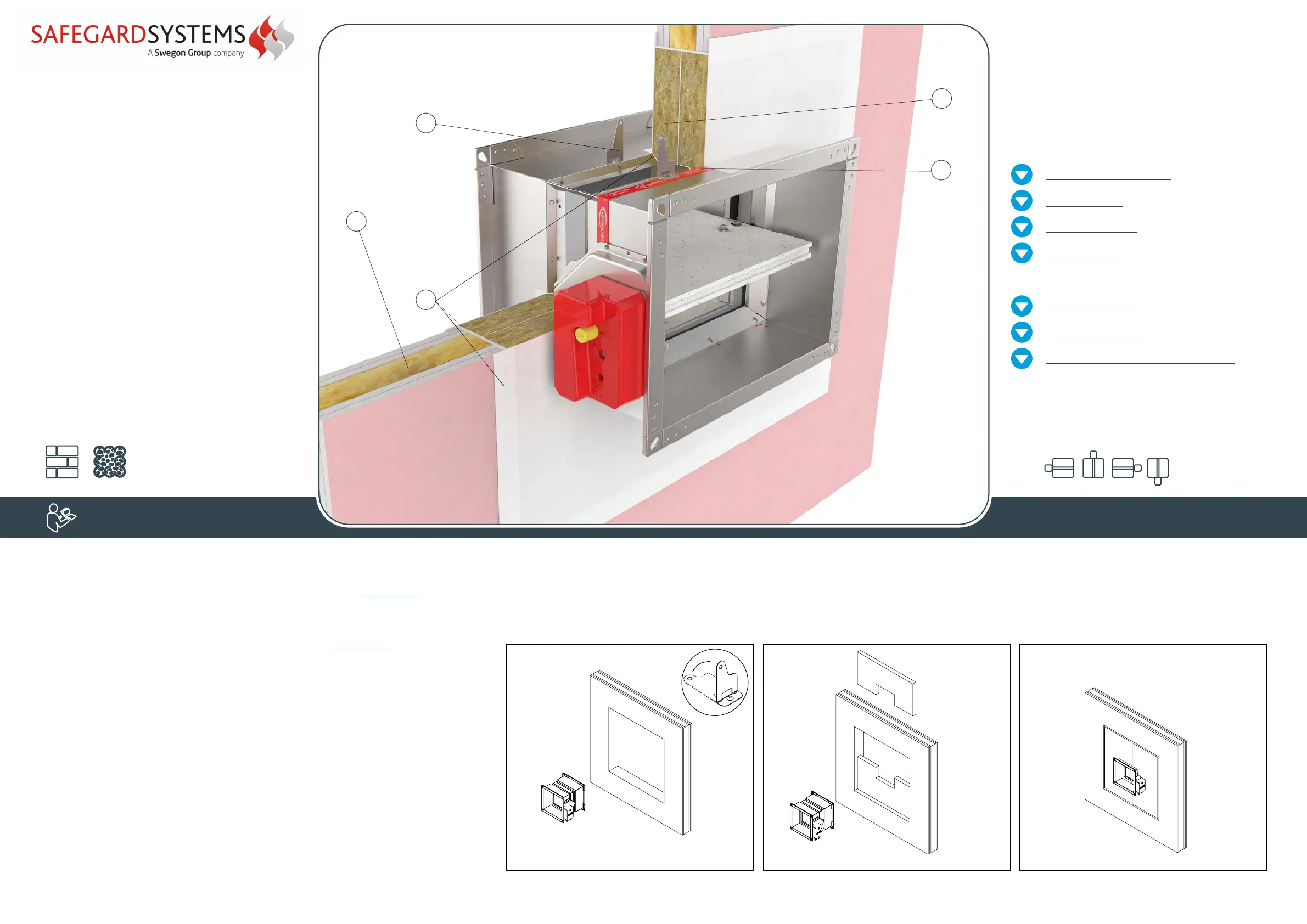

FIRE DAMPER - FD

PRODUCT OVERVIEW

DIMENSIONS

INSTALLATIONS

ACTUATORS

ACCESSORIES

REPLACEMENTS

MAINTENANCE AND OPERATION

Possible damper orientations

21

3

A

C

D

B

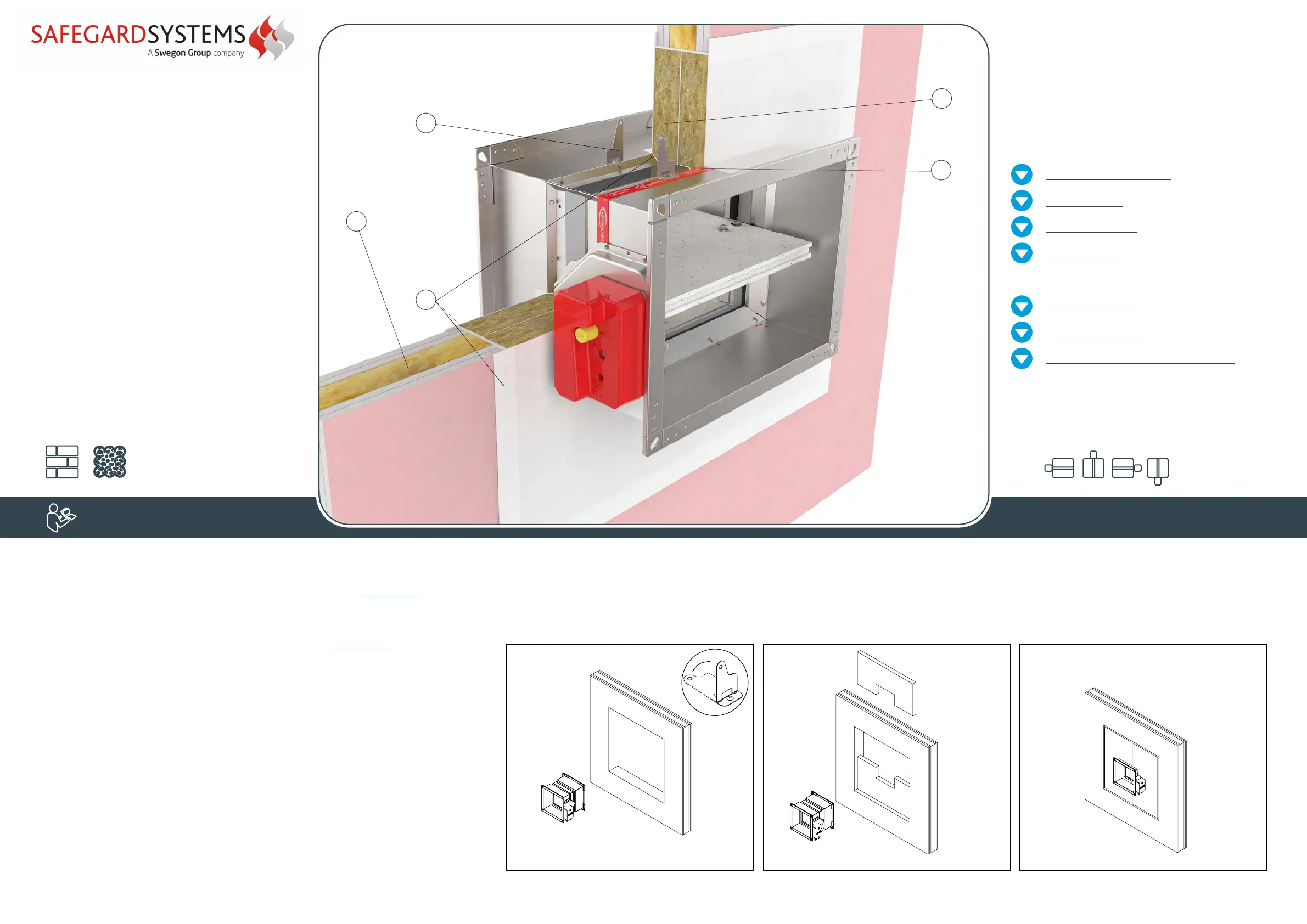

INSTALLATION

E

1. Recommended wall opening for fire

damper installation is B(H) + 100 mm.

But openings from B(H) + 80…300

mm can also be used.

Bend the fixing bracket (A) 90° (bracket

screw hole is 6 mm in diameter).

2. Insert fire damper into wall to the wall

limit mark (B) on the damper.

Damper blade must be closed during

installation!

3. Fill the space between casing and

wall, close with two layers of mineral

wool (C) (50 mm thick, coated on one

side). Seal the connections of mineral

wool with intumescent fire resistant

sealant (D). Mineral wool and damper

casing must be coated with 2 mm thick

fire protection coating.

*Multiple fire dampers can be installed

next to each other or ceiling/wall with the

minimal distance of

30 mm between them, see page 45.

**Fire Batt/ Weichschott installations adjacent to

ceiling or wall require a suspension for the fire damper.

For more details, see page 30.

Test the operation of the damper blade!

Flexible wall

installation

(Fire Batt/

Weichschott)

The wall is composed of 2x2 plasterboard boards,

12,5 mm thick, installed on a steel frame construction.

Installation material: mineral wool (C) (minimum density

of 140 kg/m³) and fire protection coating (D). The

minimum thickness of the wall is 100 mm.

EI 90 (ve i↔o)S

The wall is made out of type F (EN520) gypsum plaster

boards. To fulfill the classification it is NOT mandatory

to use the mineral wool inside the wall (mineral wool (E)

with density up to 100 kg/m³ can be used).

EI 60 (ve i↔o)S

The wall is made out of type A (EN520) gypsum plaster

boards. To fulfill the classification it is NOT mandatory

to use the mineral wool inside the wall (mineral wool (E)

with density up to 60 kg/m³ can be

used).

Always ensure the damper is sufficiently supported

Loading...

Loading...