39

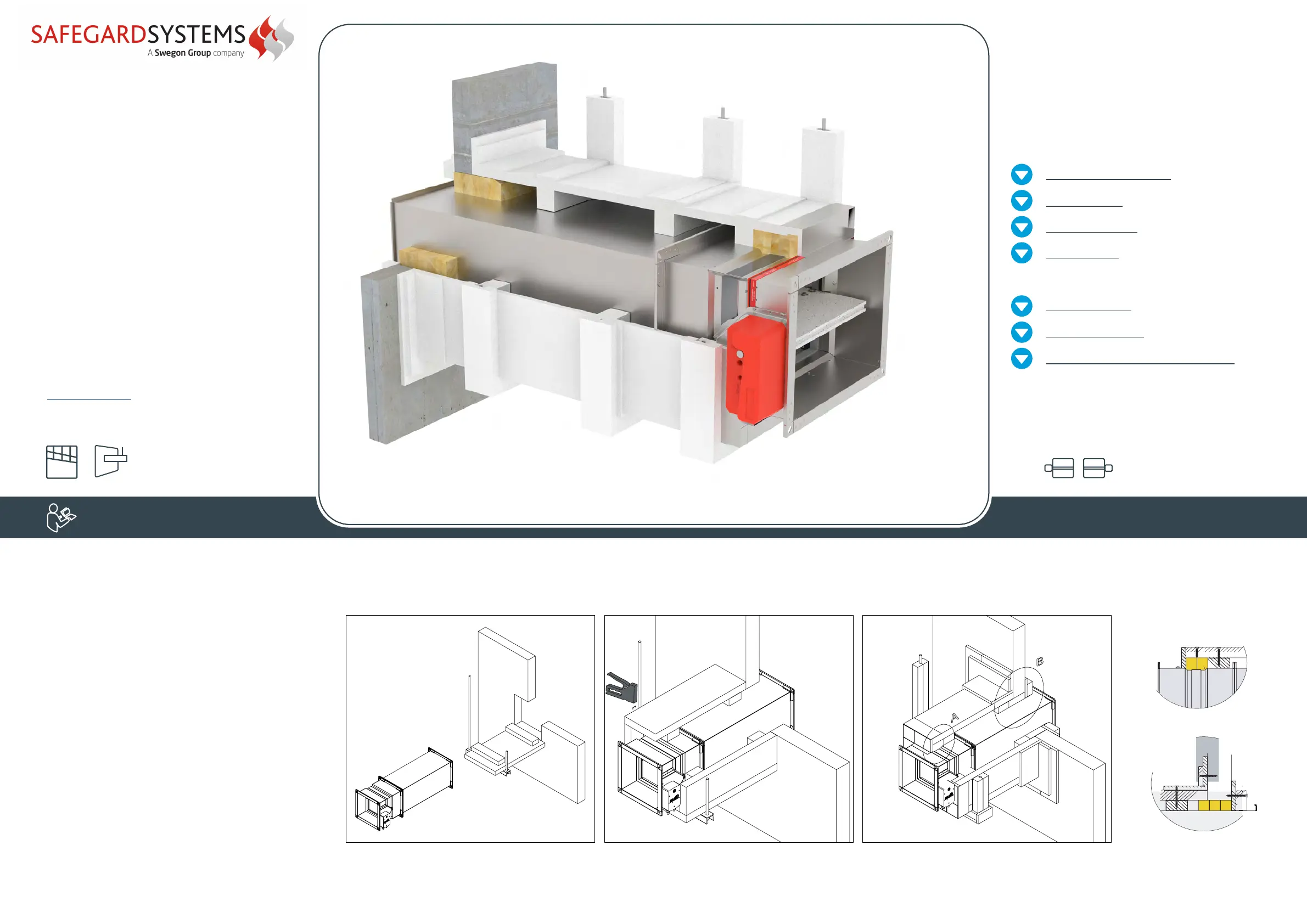

FIRE DAMPER - FD

PRODUCT OVERVIEW

DIMENSIONS

INSTALLATIONS

ACTUATORS

ACCESSORIES

REPLACEMENTS

MAINTENANCE AND OPERATION

Possible damper orientations

Technical drawing

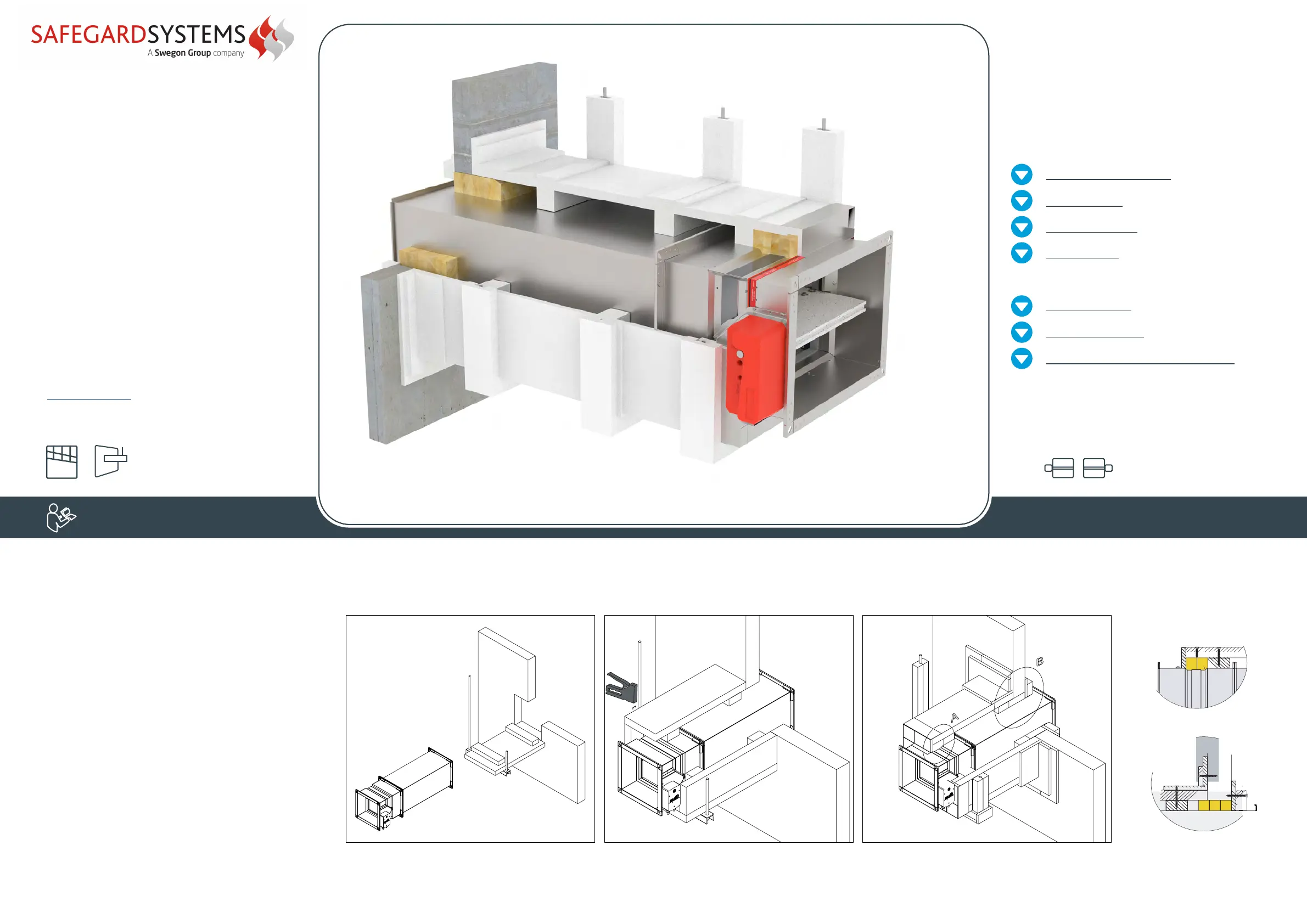

Installation remote

from the rigid wall

(Promat)

The wall is composed of concrete blocks

(minimumdensity of 550 kg/m³) or

reinforced concrete (minimum density of 2200 kg/m³)

and with a minimum thickness of 100 mm.

Installation only possible with FD40!

1. Recommended wall opening for the fire damper

installation is B (H) + 100 mm. Place fire damper and

duct on pre-cut calcium silicate 52 mm

(Promat L500), 100 mm wide supports

(max. every 1000 mm) from same material need to

be used to support the duct as well as the damper.

Damper blade must be closed during installation!

2. Fit the duct and the damper through the wall, and

cover them with 52 mm calcium silicate

(Promat L500). Board corner joints must be glued

with glue PROMAT K84 and connected with staples

every 100 mm.

3. The gap between the damper and the wall must

be filled with mineral wool (density 140 kg/m³ or

more). Close the mineral wool with Promatect H

plates 20 mm thick. Duct and damper supporting

brackets have to be insulated with 52 and 20 mm

calcium silicate boards (Promatect H and L500).

Test the operation of the damper blade!

2

1

3

A

B

INSTALLATION

Always ensure the damper is sufficiently supported

Loading...

Loading...