41

FIRE DAMPER - FD

PRODUCT OVERVIEW

DIMENSIONS

INSTALLATIONS

ACTUATORS

ACCESSORIES

REPLACEMENTS

MAINTENANCE AND OPERATION

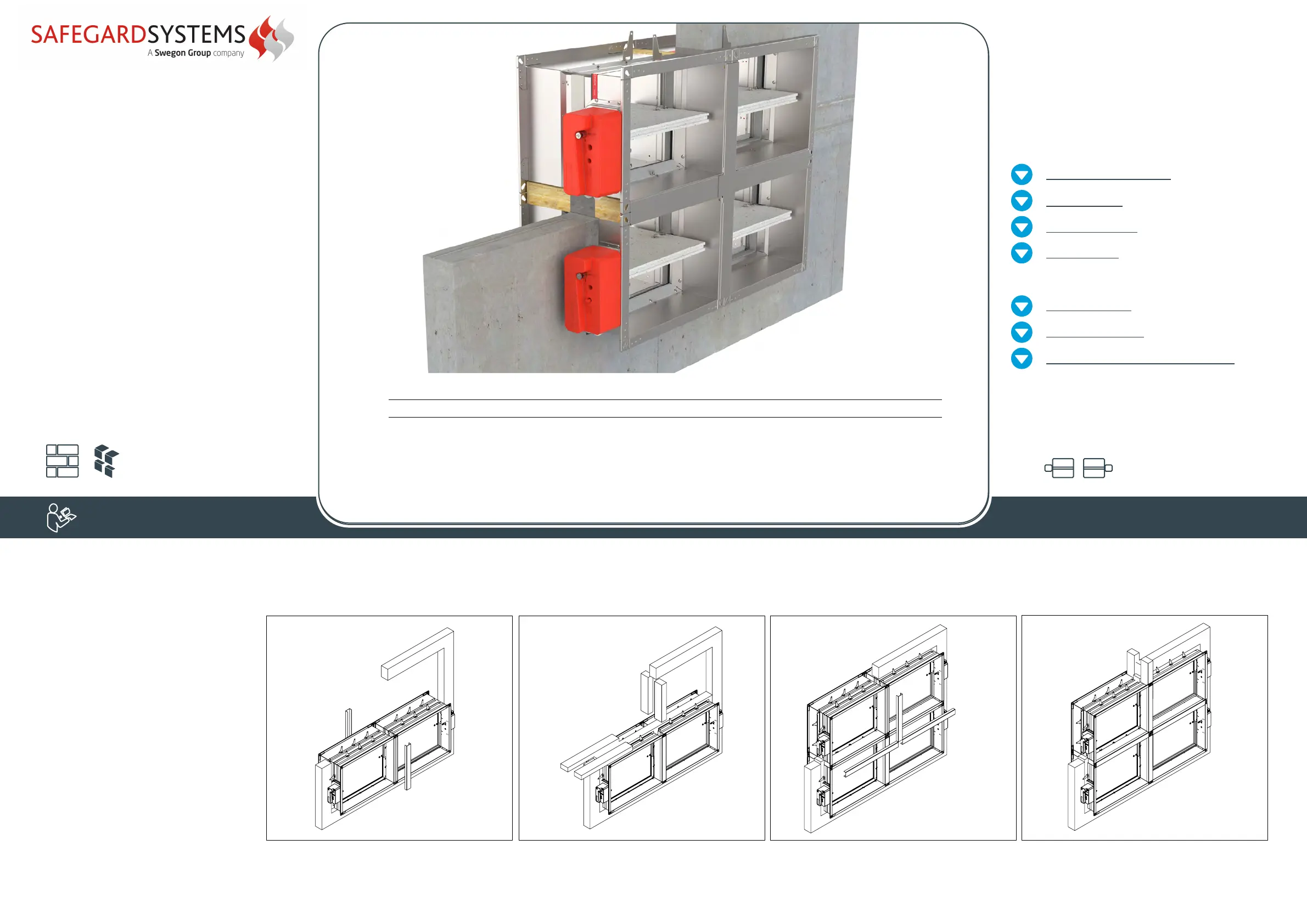

Possible damper orientations

Battery assembly

installation

2x2

The wall is composed of concrete blocks

(minimum density of 550 kg/m³) or

reinforced concrete (minimum density of 2200 kg/m³)

and with a minimum thickness of 100 mm.

2

1

43

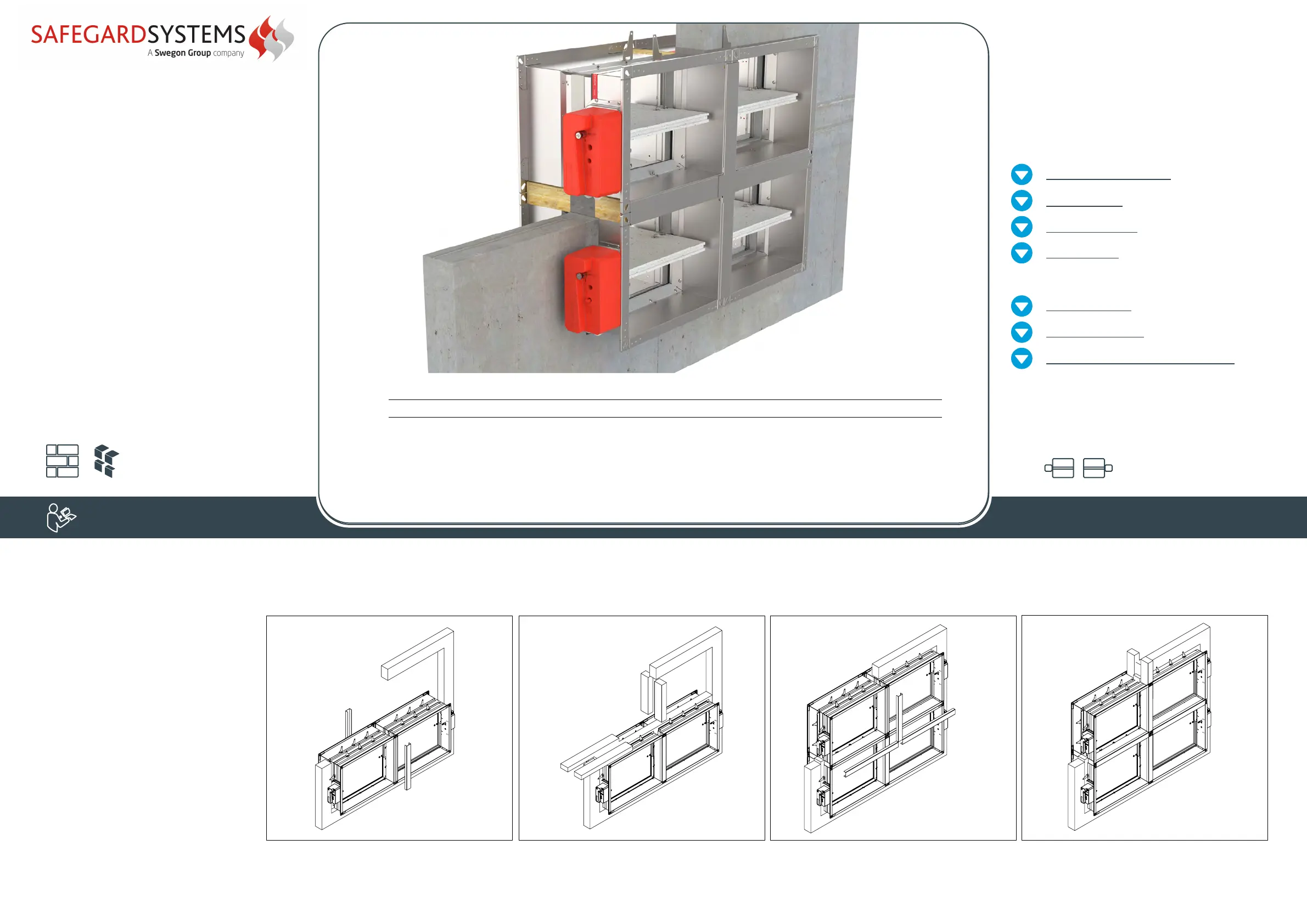

1. Prepare a hole of dimensions

2B + Connecting frame width (CF60/

CF100) + 80 mm and 2H + Connecting

frame width (CF60/CF100) + 80 mm.

Fill the bottom with mortar/gypsum in 50

mm height.

2. Place two lower dampers in the opening,

and fix dampers to the wall using screws

(only 2 sides facing aerated concrete).

Place the vertical part from the installation

kit to the dampers on both sides, and

attach it using the self-tapping screws.

Damper blade must be closed during

installation!

3. Fill the space between the dampers and

the wall with mortar/gypsum, and fill the

space between the dampers with mineral

wool (100 kg/m³ of density or higher).

Place two upper dampers and fix the

dampers to the wall using the screws (only

2 sides facing aerated concrete).

4. Place the vertical part and two horizontal parts from the installation kit to the dampers on both sides, and attach it using the self-tapping screws every

150 mm. Fill the gap between dampers and wall on upper side with mortar/gypsum and the installation is complete.

Test the operation of the damper blade!

Maximum dimension of fire dampers:

2X2 grid: 1500x800 mm

*For battery installation 2x2 use 8x connecting

frames and 2x connecting plate.

Installation only possible with FD40!

(1) Accessories (2) Type (3) Length

FD-A - CF60 - 800

(1)

(2)

Fire damper accessories

FD-A

Type

CF60 - Connecting frame 60 mm

CF100 - Connecting frame 100 mm

CP60- Connecting plate 60 mm

CP100- Connecting plate 100 mm

(3) Connecting frame length

200 ... 1500 [mm]

INSTALLATION

Always ensure the damper is sufficiently supported

Loading...

Loading...