8

F 50

1

2

34

1

3

2

4

1

2

F50 / F75

Doc: 101425E-GB 1406

DAILY CHECKS

Fuel Check

Check that there is fuel in the tank. Top up if necessary.

Engine Oil Level Check

Check the oil level in the crankcase every day. The oil

must reach the edge of the lling hole when the machine is

on a level surface.

Air Filter Check

The air lter must be checked at least once every working week.

When working in dusty conditions, check daily.

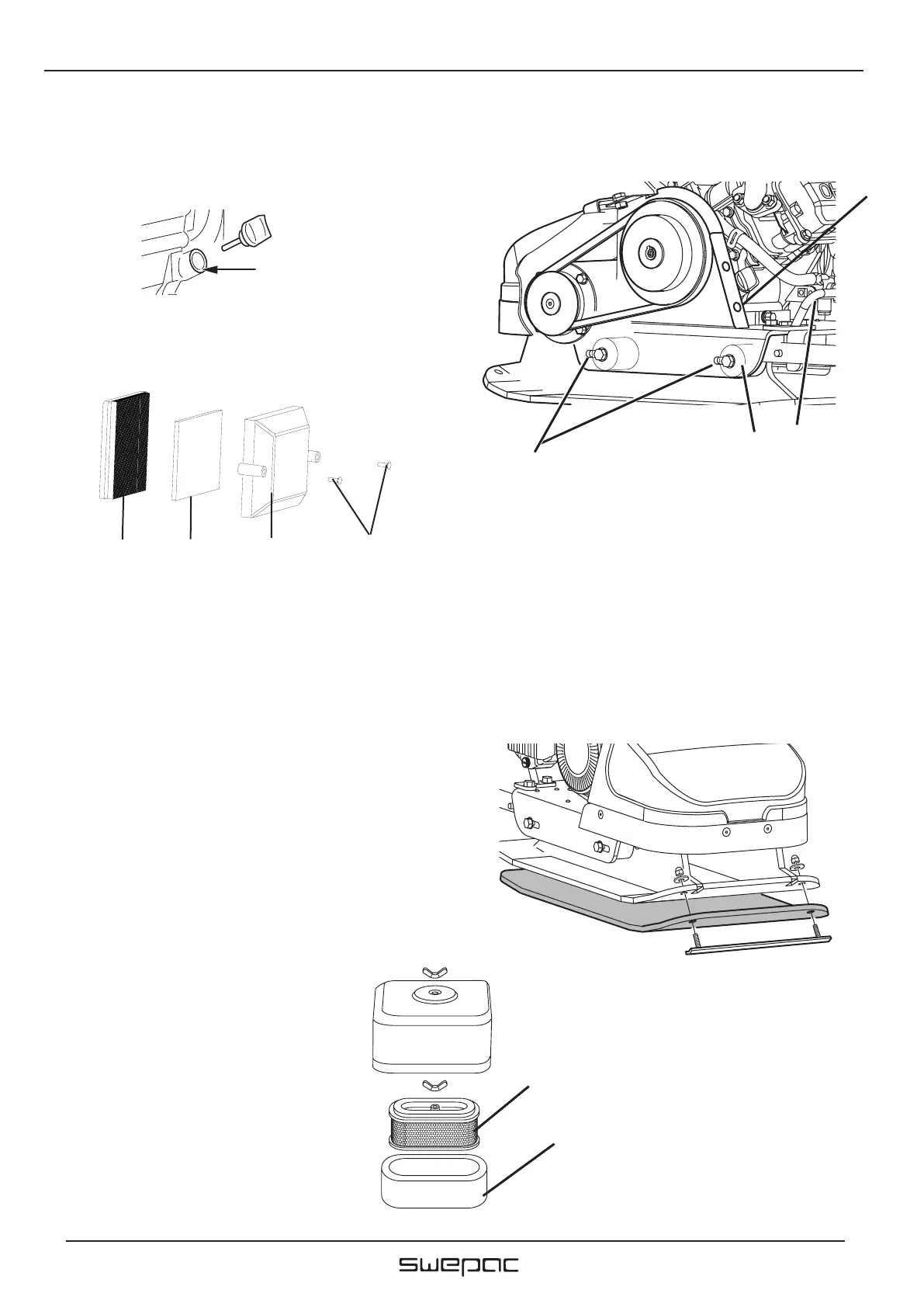

Cleaning the air lter GX 100 engine

1. Loosen screws (1) and remove the cover (2). Clean the

dust off the cover

2. Clean the pre-cleaner (3) with cleanser and water.

Saturate the precleaner in engine oil. Squeeze dry in

clean absorbent cloth.

3. Clean the cartridge (4) by tapping it gently on a at

surface.

NOTE! Renew a damaged cartridge.

4. Remount the lter unit in opposit order.

Air Filter Check GX120

1. Paper element

2. Foam plastic element

Cleaning the air lter

1. Remove the foam plastic element and the

paper element and check that they are

undamaged. Replace damaged parts.

2. Wash the foam plastic element in liquid with

a high ashpoint and let it dry properly. Dip in

engine oil and squeeze dry.

3. Strike the paper element against a hard object

a few times to loosen any dirt.

Oil/Fuel Leakage

Check every day that the engine is not leaking oil

or fuel. If a leak is discovered, the machine may

not be operated until the fault has been remedied.

See also the separate engine instructions!

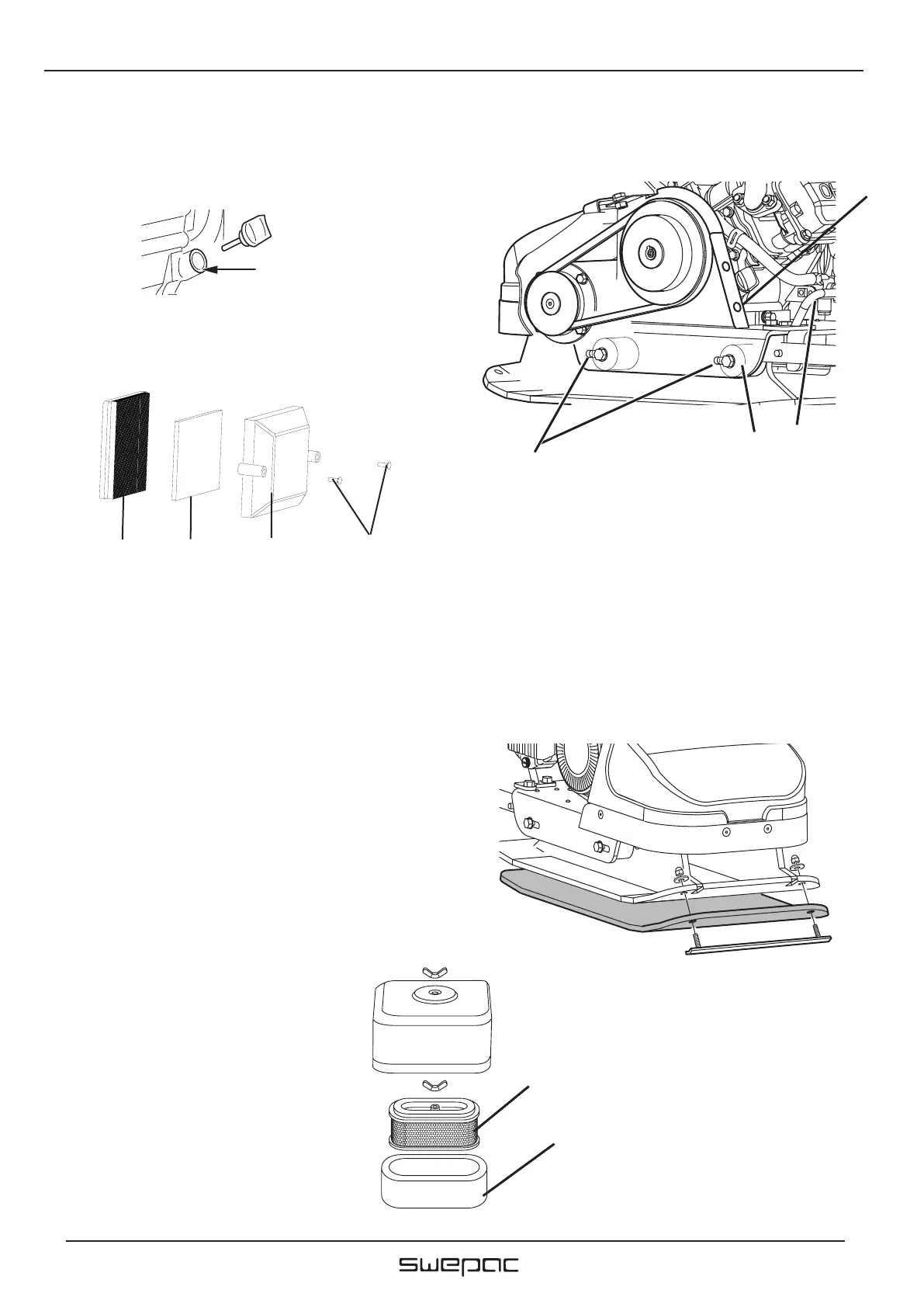

V-belt Drive

Check the tension and condition of the V-belt regularly.

Replace a damaged V-belt with the new type XPZ750

for F50 and A28 for F75.

Adjustment of V-belt tension

Loosen the screws (1, 4 pcs) that hold the engine plate.

Loosen the screws (2, 3 pcs) holding the cover.

Remove the cover.

Tension the V-belt by pulling the handle (3).

Tighten the screws.

Ret the cover.

Rubber Dampers

Check the condition of the rubber dampers (4, 4 pcs)

regularly. Replace damaged dampers.

Polyuretan Pad

A polyuretan pad is used for stone paving work to protect

against stones and ground clinker.

Loading...

Loading...