8

FB 430 / FB 450 / FB 500 / FB 510

FB 430 / FB 450 FB 500 / FB 510

1 2

3

4

5

FB 430 / FB 450

1 2

3

4

5

FB 500 / FB 510

Dok: 101498D-GB 2103

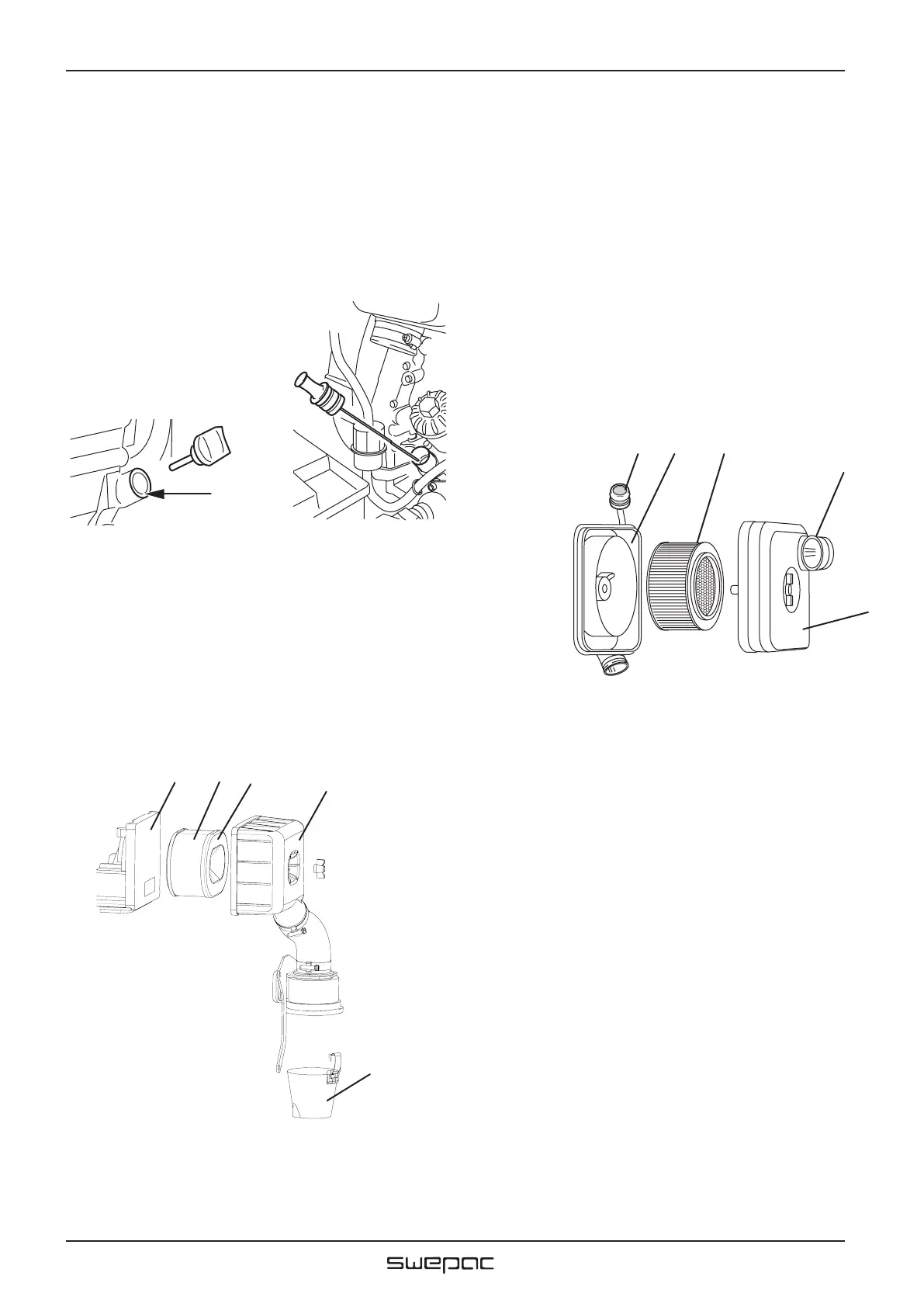

1. Indicator

2. Filter plate

3. Filter

4. Air intake with cyclone

5. Filter cover

Cleaning

With the engine at full RPM, press in the indicator (1) for the

air lter. If it remains depressed, clean the llter as described

below. This may need to be done several times a day in dusty

conditions.

1. Loosen the wing screw in the llter cap (5). Check that the

dust outlet (4) is not clogged. Clean it if necessary.

2. Loosen the llter (3) and blow it clean with dry

compressed air, max. 5 bar, from the inside until no more

dust comes out. Replace a damaged llter.

3. Check that the lter plate (2) in the lter housing is clean.

DAILY CHECKS

Oil/Fuel Leakage

Check every day that the engine is not leaking oil or fuel. If a

leak is discovered, the machine may not be operated until the

fault has been remedied.

Air Filter Check

The air lter must be checked at least once every working

week. When working in dusty conditions, check daily.

Fuel Check

Check that there is fuel in the tank. Top up if necessary.

Engine Oil Level Check

Check the oil level in the crankcase every day. Turn o the

engine. The machine is on a level surface.

FB430 / FB 450: The oil must reach the edge of the lling

hole.

FB 500 / FB 510: The oil must reach up to the “MAX”

marking.

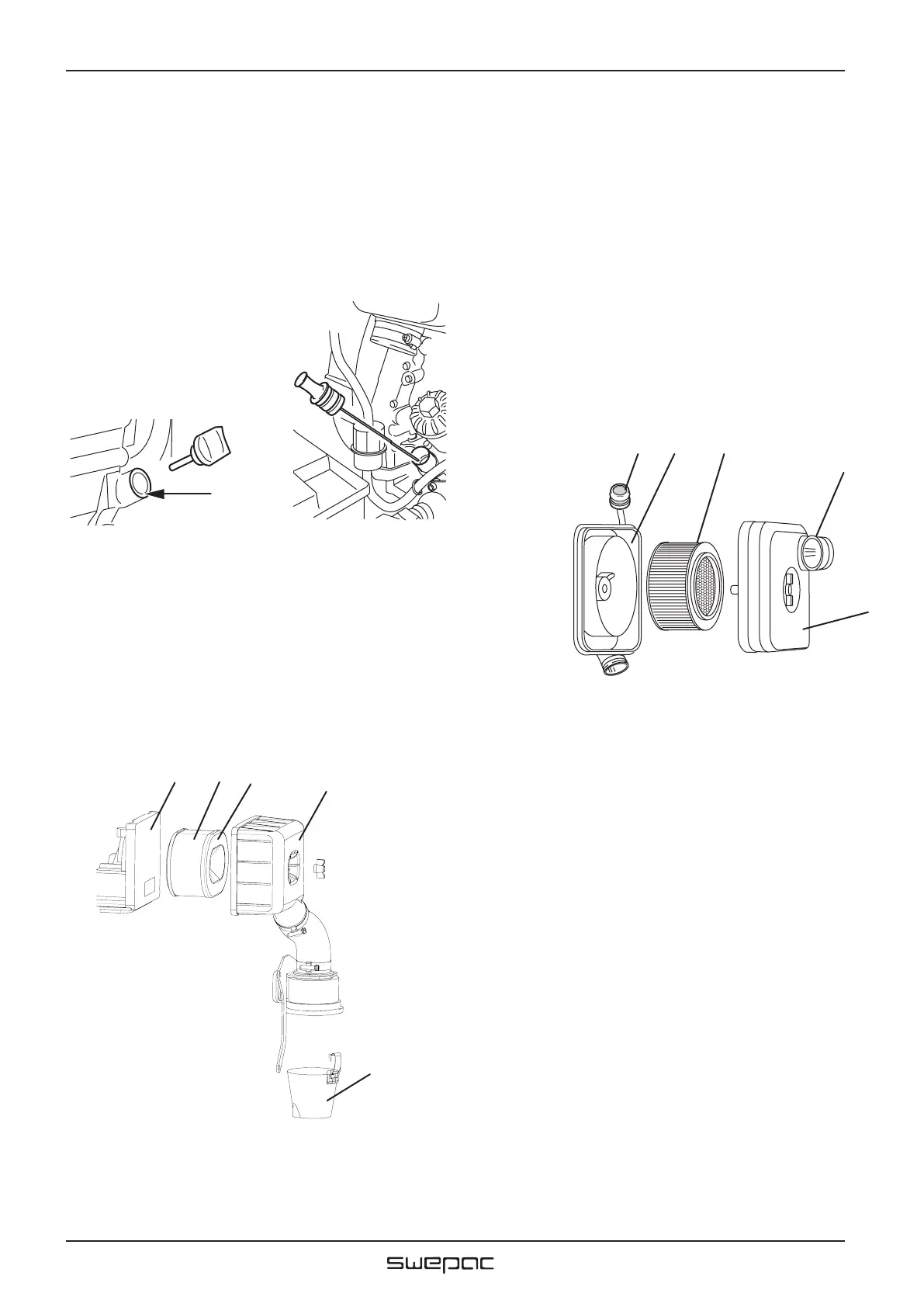

1. Filter plate

2. Foam plastic element

3. Paper element

4. Filter cover

5. Cyclone lter collector

Cleaning

1. Remove the foam plastic element and the paper element

and check that they are undamaged. Replace damaged parts.

2. Wash the foam plastic element in liquid with a high as-

hpoint and let it dry properl. Dip in engine oil and squeeze

dry.

3. Strike the paper element against a hard object a few times

to loosen any dirt.

4. Check that the lter plate is clean. Clear the cyclone lter

collector.

Loading...

Loading...