8-2

Error Type Cause

① Incorrect position of needle

stop

② Failure to sense signals for

needle position or 1 rotation

③ Incorrect position of needle

bar

④ Incorrect position of take-up

lever

⑤ Bad connection

Inspection & Repair

Refer to user’s manual

Run manual color change and

check if signal lamps (needle

set lamp & needle position

lamp) blinks at correct needle

position. Adjust the half-turn

film.

Set it to the correct position

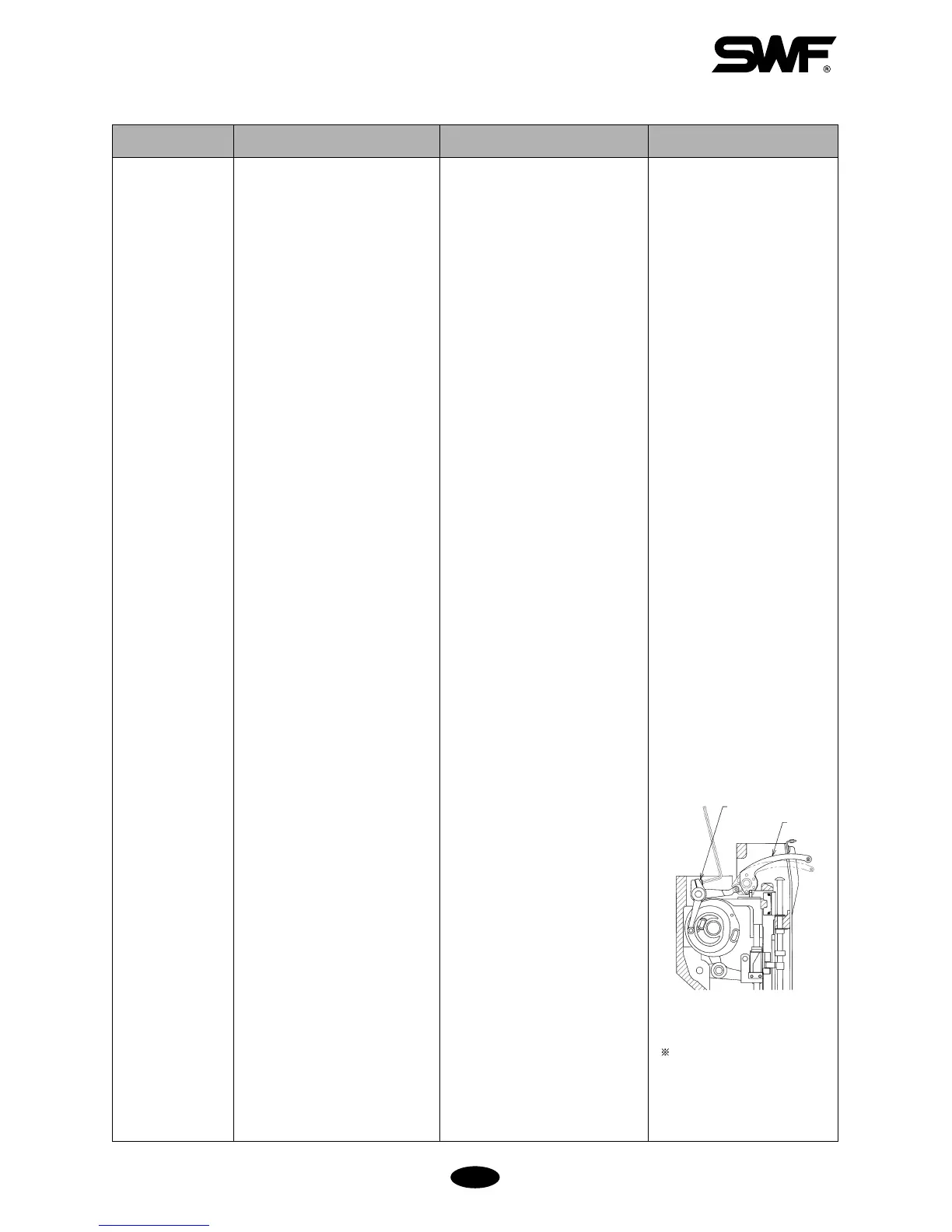

Adjust so take-up lever is in

line with other levers in stop

position (upper shaft

angle:100°)

Change fuse F3 in joint board

or check connection

Set main shaft angle back at

100°, if you manually moved

it for cleaning, inspection or

repair.

※ Adjusting position of

take-up lever

Unscrew the lever and

adjust so it is in line with

other take-up levers on

the guide rail.

Check fuse spec.

Reference

Bad Color

Change

take-up

lever

screw

take-up

lever

Loading...

Loading...