1-7-1 T5307EA

ELECTRICAL ADJUSTMENT INSTRUCTIONS

General Note:

"CBA" is abbreviation for "Circuit Board

Assembly."

NOTE:

Electrical adjustments are required after replacing

circuit components and certain mechanical parts.

It is important to perform these adjustments only

after all repairs and replacements have been com-

pleted.

Also, do not attempt these adjustments unless the

proper equipment is available.

Test Equipment Required

1. NTSC Pattern Generator (Color Bar W/White Win-

dow, Red Color, Dot Pattern, Gray Scale, Mono-

scope, Multi-Burst)

2. AC Milli Voltmeter (RMS)

3. Alignment Tape (FL8A, FL8N), Blank Tape

4. DC Voltmeter

5. Oscilloscope: Dual-trace with 10:1 probe,

V-Range: 0.001~50V/Div,

F-Range: DC~AC-60MHz

6. Frequency Counter

7. Plastic Tip Driver

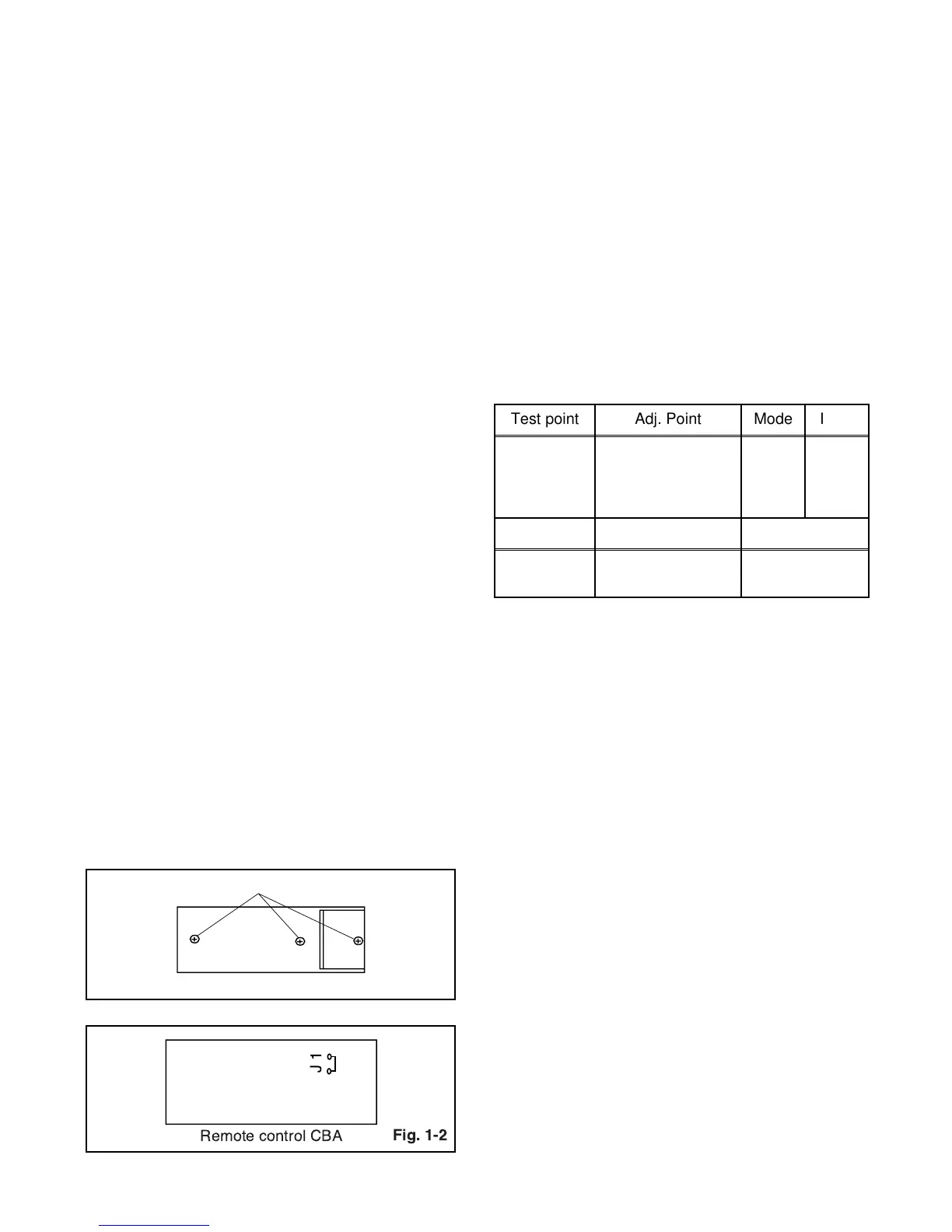

How to make service remote control

unit:

1. Prepare normal remote control unit. (Part No.

N0107UD) Remove 3 screws from the back lid.

(Fig. 1-1)

2. Add J1 (Jumper Wire) to the remote control CBA.

(Fig. 1-2)

How to Set up the Service mode:

Service Mode:

1. Use the service remote control unit.

2. Turn the power on.

3. Press " WAKE-UP/SLEEP " button on the service

remote control unit.

1. DC 105V (+B) Adjustment

[ SRC2213/SRC22134 ]

Purpose: To obtain correct operation.

Symptom of Misadjustment: The picture is dark and

unit does not operate correctly.

Note: J192(+B), J213(GND), VR601 --- Main CBA

1. Connect the unit to AC Power Outlet.

2. Connect DC Volt Meter to J192(+B) and

J213(GND).

3. Adjust VR601 so that the voltage of J192(+B)

becomes +105±0.5V DC.

SCREW

Fig. 1-1

Remote control unit (Bottom)

J1

Remote control CBA

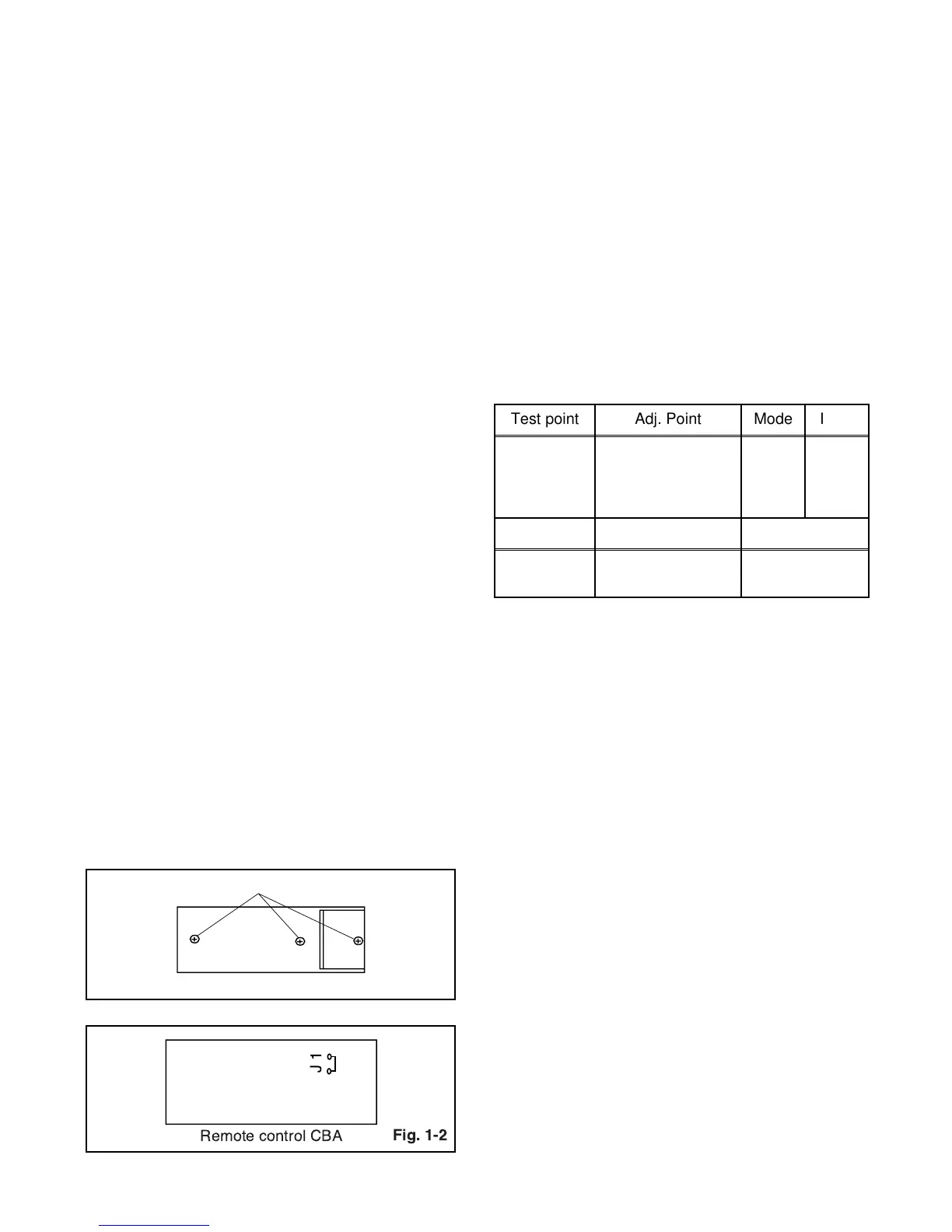

Test point Adj. Point Mode Input

J192

(+B)

J213

(GND)

VR601 --- -----

Tape M. EQ. Spec.

---

DC Voltmeter

Plastic Tip Driver

+105±0.5V DC

Loading...

Loading...