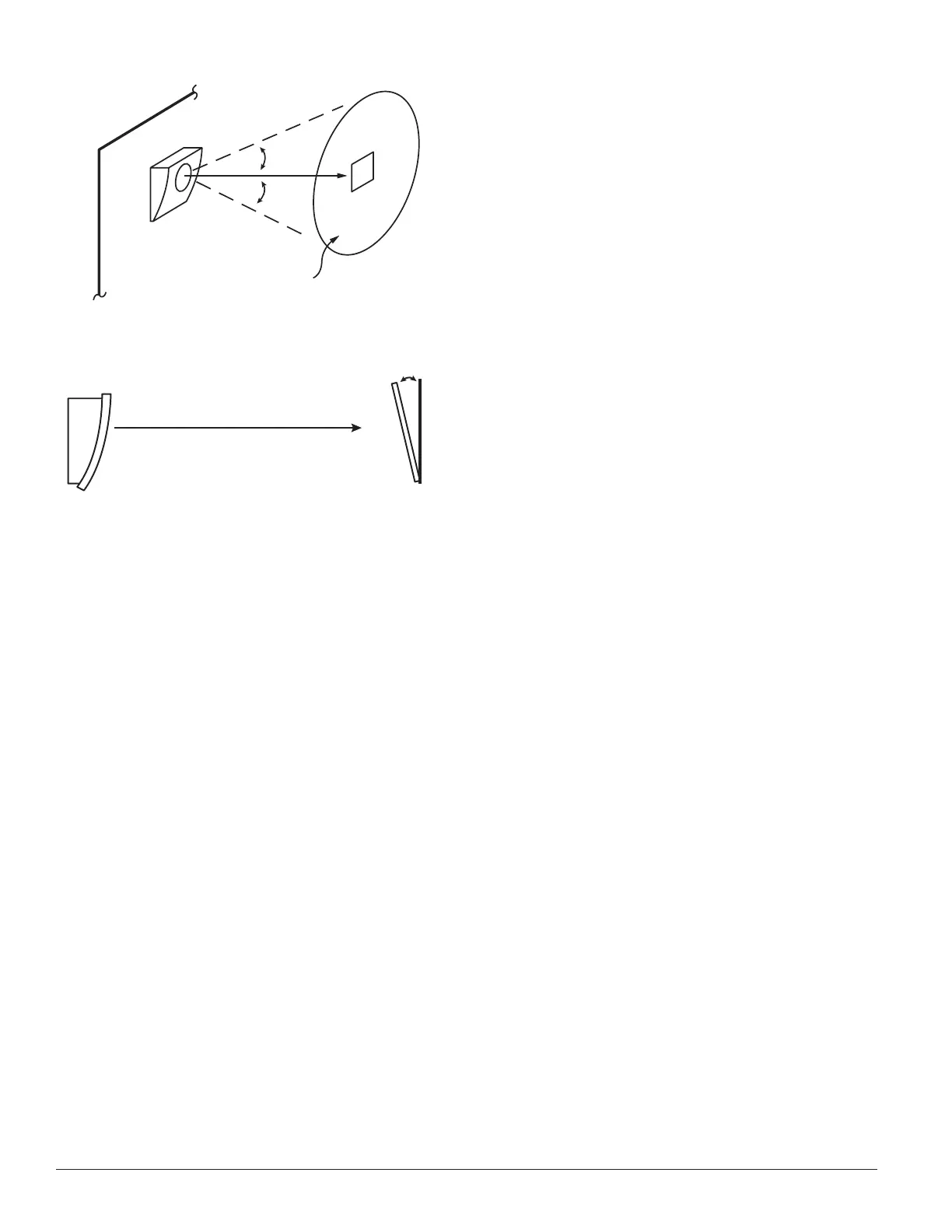

Figure 5a. Reflector Mounting Guidelines

WALL

REFLECTOR

Acceptable mounting

locations for reflector

10°

10°

C0258-00

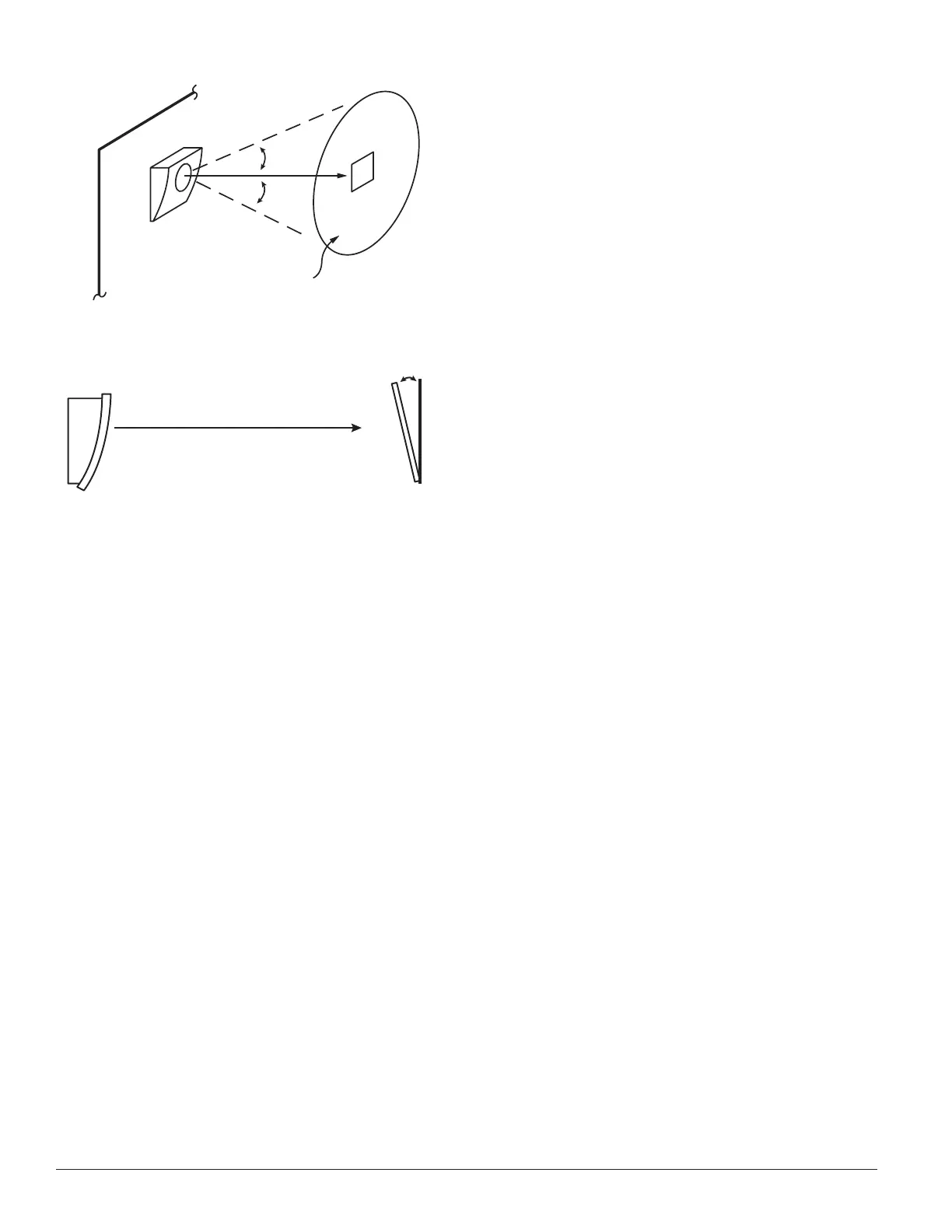

Figure 5b. Reflector Mounting Guidelines

10° maximum

optical line of sight

REFLECTOR

C0259-00

Mounting Considerations for Single Ended Beam

Detectors

There must be a permanent clear line of vision between the

detector and the reflector. Reflective objects must not be

near the line of vision between the detector and reflector.

Reflective objects too near to the line of sight can reflect

the light beam from the transmitter to the receiver. If this

occurs, the detector will not be able to distinguish these

reflections from those of the reflector and the protected

space will be compromised. Reflective objects should be

a minimum of 15 inches (38.1cm) from the line of sight

between the detector and reflector. In cases where reflective

objects cannot be avoided, the complete reflector blockage

test can be used to determine if the installation is accept-

able. See Testing and Maintenance Section of this manual.

Light sources of extreme intensity such as sunlight and hal-

ogen lamps, if directed at the receiver, can cause a dramatic

signal change resulting in fault and alarm signals. To prevent

this problem direct sunlight into the transmitter/receiver

unit should be avoided. There should be a minimum of 10°

between the pathway of the light source and detector and

the line of sight between detector and reflector.

Operation of the detector through panes of glass should

be avoided. Since single ended beam detectors operate on

a reflection principle, a pane of glass perpendicular to the

line of sight between the detector and the reflector can

reflect the light beam from the transmitter to the receiver.

If this occurs, the detector will not be able to distinguish

these reflections from those of the reflector and the pro-

tected space will be compromised.

Panes of glass will also absorb some of the light as it passes

through it. This absorption of light will reduce the acceptable

installed distance between the detector and the reflector.

In cases where operation through panes of glass cannot be

avoided some specific installation practices can help to mini-

mize the effects of the glass. These practices include: avoid

penetration of multiple panes of glass, position the glass so

that it is not perpendicular to the line of sight between the

detector and the reflector, (A minimum of 10° off perpen-

dicular should be considered), and make certain that the

glass is smooth, clear and mounted securely. The complete

reflector blockage test can be used to determine if the instal-

lation is acceptable. See Testing and Maintenance Section of

this manual.

Where high ceilings (in excess of 30 feet or 9.1 meters) are

present additional beams may be required to detect smoke at

lower levels. See System Sensor’s Projected Beam Detector

Applications Guide for further explanation.

Wiring Installation Guidelines

Always install all wiring in compliance with the National

Electrical Code, and/or the applicable local codes, and any

special requirements of the local authority having jurisdiction.

Proper wire gauges and suitable means for strain relief should

be used. The conductors used to connect beam smoke detec-

tors to control panels and accessory devices should be color-

coded to reduce the likelihood of wiring errors. Improper

connections can prevent a system from responding properly

in the event of a fire.

Installation wire used for the beam detector shall be no smaller

than 22 AWG (1.0 mm

2

). For best system performance, all wir-

ing should be twisted pair and installed in separate grounded

conduit. Do NOT mix fire system wiring in the same conduit

as any other electrical wiring. Shielded cable may be used to

provide additional protection against electrical interference.

When installing the beam smoke detector in applications

where the head unit will be mounted to either a wall or the

ceiling using the multi-mount kit (BEAMMMK) flexible con-

duit will be used. The surface mount kit (BEAMSMK) and

multi-mount kit (BEAMMMK) must be installed with the

cable before wring the unit, according to the instructions sup-

plied with the kit.

When the detector has been mounted over a recessed junction

box, all wiring should be routed out of the box and behind

the detector to the bottom of the detector where the terminal

blocks are located. When installing the wiring in the junction

D400-73-00 6 I56-2294-03R

Loading...

Loading...