pilot holes at target “A” centers and cut two 1.375 inch diameter holes using

a 1

3

/8 inch hole saw or punch. Drill .156 inch diameter holes using a

5

/32 inch

drill at target “C” centers. If desired, drill an additional .156 inch hole at the

location of one of the mounting tabs on the lower housing.

[5.4] SECURE THE DUCT DETECTOR TO THE DUCT

Use two (rectangular configuration) or three (square configuration) of the pro-

vided sheet metal screws to screw the duct detector to the duct.

CAUTION: Do not overtighten the screws.

[6] SAMPLING TUBE INSTALLATION

[6.1] SAMPLING TUBE SELECTION

The sampling tube must be purchased separately. Order the correct length,

as specified in Table 1, for width of the duct where it will be installed. It is rec-

ommended that the sampling tube length extend at least

2

/3 across the duct

width for optimal performance.

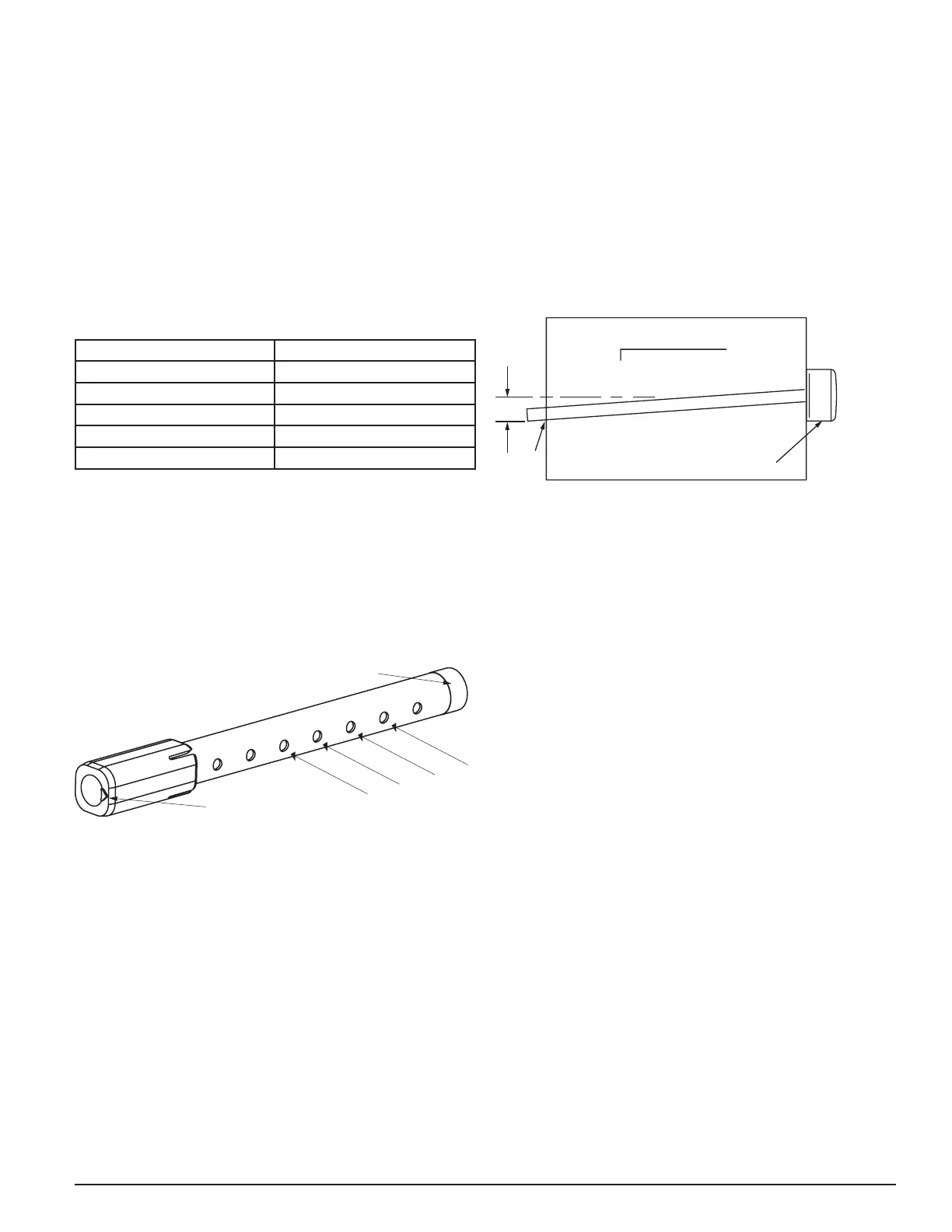

TABLE 1. SAMPLING TUBES RECOMMENDED FOR DIFFERENT

DUCT WIDTHS

Outside Duct Width Sampling Tube Recommended*

Up to 1 ft. DST1

1 to 2 ft. DST1.5

2 to 4 ft. DST3

4 to 8 ft. DST5

8 to 12 ft. DST10 (2-piece)

*Must extend a minimum of

2

/3 the duct width. These sampling tubes can only

be used with new InnovairFlex duct smoke detectors.

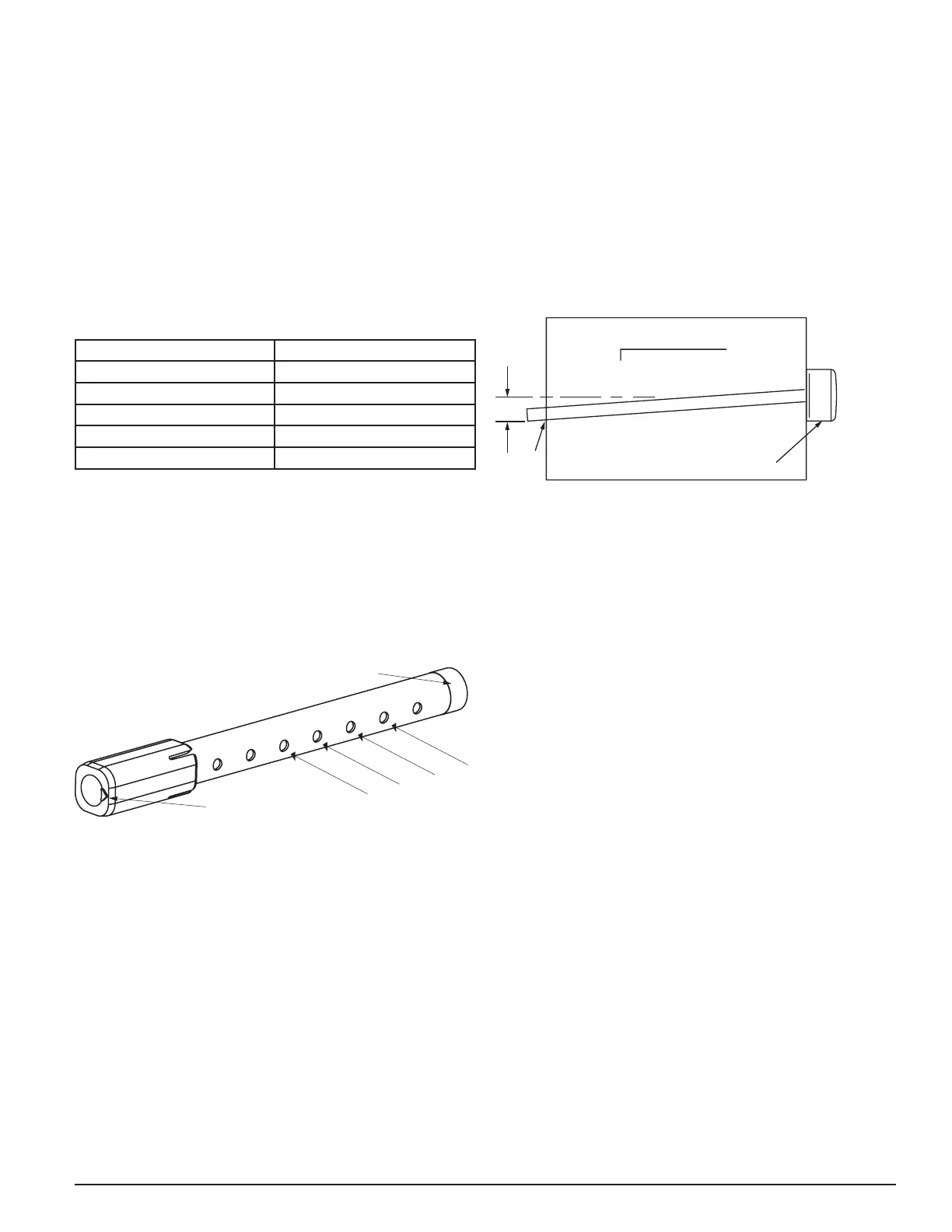

The sampling tube is always installed with the air inlet holes facing into the

air flow. To assist proper installation, the tube’s connector is marked with an

arrow. Make sure the sampling tube is mounted so that the arrow points into

the airflow as shown in Figure 3. Mounting the detector housing in a vertical

orientation is acceptable provided that the air flows directly into the sampling

tube holes as indicated in Figure 3. The sampling tube and exhaust tube

can be mounted in either housing connection as long as the exhaust tube is

mounted downstream from the sampling tube.

FIGURE 3. AIR DUCT DETECTOR SAMPLING TUBE

ARROW MUST FACE

INTO AIR FLOW

AIR FLOW

DIRECTION

H0551-00

CAUTION: The sampling tube end cap, included with the detector, is critical

to proper operation of the duct smoke detector. The end cap is needed to

create the proper air flow to the sensor of the duct smoke detector. Once any

sampling tube length adjustments are made, plug the end of the sampling

tube with the provided end cap.

A plastic exhaust tube is included with the unit to be installed if needed. Install

into the housing connection that is downstream from the sampling tube con-

nection. The exhaust tube can be installed from the front or back of the detec-

tor. A longer 1 foot exhaust tube, model ETX, is available as an accessory in

cases where the molded exhaust tube does not extend at least 2 inches into

the duct.

[6.2] SAMPLING TUBE INSTALLATION

1. For tubes shorter than the width of the duct, slide the sampling tube,

with installed end cap, into the housing connection that meets the airflow

first. Position the tube so the arrow points into the airflow as shown in

Figure 3. Per NFPA sampling tubes over 3 feet long should be sup-

ported at the end opposite the duct detector. In ducts wider than 8 feet,

work must be performed inside the duct to couple the other section of

the sampling tube to the section already installed using the

1

/2 inch con-

duit fitting. Make sure that the holes on both sections of the air inlet

sampling tube are lined up and facing into the airflow.

2. For tubes longer than the width of the duct, the tube should extend out of

the opposite side of the duct. Drill a

3

/4 inch hole in the duct opposite the

hole already cut for the sampling tube. Ensure that the sampling tube

is angled downward from the duct smoke detector to allow for moisture

drainage away from the detector. The sampling tube should be angled

at least 1/4” downward for every 12” of duct width per Figure 4. There

should be 10 to 12 holes spaced as evenly as possible across the width

of the duct. If there are more than 2 holes in the section of the tube ex-

tending out of the duct, select a shorter tube using Table 1. Otherwise,

trim the tube to leave approximately 1 to 2 inches extending outside

the duct. Plug the end with the end cap and tape closed any holes in

the protruding section of tube. Be sure to seal the duct where the tube

protrudes.

FIGURE 4.

DETECTOR

3

/

4

˝

HOLE

12˝

1

/

4

˝

2˝

H0215-00

NOTE: Air currents inside the duct may cause excessive vibration, espe-

cially when the longer sampling tubes are used. In these cases, a 3 inch floor

flange (available at most plumbing supply stores) may be used to fasten the

sampling tube to the other side of the duct. When using the flange/connector

mounting technique, drill a 1 to 1

1

/4 inch hole where the flange will be used.

[6.3] MODIFICATIONS OF SAMPLING TUBES

There may be applications where duct widths are not what is specified for the

installation. In such cases, it is permissible to modify a sampling tube that is

longer than necessary to span the duct width.

Use a 0.193 inch diameter (#10) drill and add the appropriate number of

holes so that the total number of holes exposed to the air flow in the duct is

10 to 12. Space the additional holes as evenly as possible over the length of

the tube.

NOTE: This procedure should only be used as a temporary fix and is not

intended as a substitute for ordering the correct length tubes.

[7] MEASUREMENT TESTS

[7.1] AIR FLOW

The D4120A is designed to operate over an extended air speed range of

100 to 4000 FPM. To verify sufficient sampling of ducted air, turn the air han-

dler on and use a manometer to measure the differential pressure between

the two sampling tubes. The differential pressure should measure at least

0.01 inches of water and no more than 1.11 inches of water. Because most

commercially available manometers cannot accurately measure very low

pressure differentials, applications with less than 500 FPM of air speed may

require one of the following: 1) the use of a current-sourcing pressure trans-

mitter (Dwyer Series 607) per Section 7.2, or 2) the use of aerosol smoke per

section 12.5.3.

[7.2] LOW FLOW AIR FLOW TEST USING DWYER SERIES 607

DIFFERENTIAL PRESSURE TRANSMITTER

Verify the air speed of the duct using an anemometer. Air speed must be at

least 100 FPM. Wire the Dwyer transmitter as shown in Figure 5. Connect

the leads of the meter to either side of the 1000Ω resistor. Allow unit to warm

up for 15 seconds. With both HIGH and LOW pressure ports open to ambient

air, measure and record the voltage drop across the 1000Ω resistor (mea-

surement 1), 4.00 volts is typical. Using flexible tubing and rubber stoppers,

connect the HIGH side of the transmitter to the sampling tube of the duct

smoke detector housing, and the LOW side of the transmitter to the exhaust

tube of the duct smoke detector housing. Measure and record the voltage

drop across the 1000Ω resistor (measurement 2). Subtract the voltage re-

corded in measurement 1 from the voltage recorded in measurement 2. If the

3 I56-3102-003

7/8/2019

Loading...

Loading...