D770-08-00 3 I56-551-02

Adjustments To Factory Settings

Both EPS10-1 and EPS10-2 devices are pre-adjusted at the

factory to alarm at 4–8 PSI on rising pressure (see Table 2).

Pressure switch settings may be adjusted in the field to ob-

tain a different pressure alarm response from 4 PSI to 20

PSI. The switch has an override feature on the adjustment

mechanism to prevent exceeding the 20 PSI max. setting of

the switch. This override feature carries with it a tolerance

band that may limit the upper adjustment to 16–20 PSI.

Care must be used when setting the switch to ensure that

the lower limit of 4 PSI is not exceeded. This will allow the

switch to reset within the 3 PSI differential stated.

1. Install pressure switch as stated in “INSTALLATION”

portion of instruction manual. Attach pressure test

source to system.

2. Back off locking screw (see Figure 1) to allow main ad-

justment wheel to rotate freely.

3. Test set point by slowly introducing pressure from the

pressure test source. When set point is found, reduce

pressure to zero. Rotate main adjustment wheel (coun-

terclockwise to increase pressure) and retest until switch

trip point is at the desired pressure setting (4–20 PSI

range). The approximate sensitivity of the adjustment

wheel: 1 turn = 2.5 PSI. A reset differential of approxi-

mately 3 PSI is typical throughout the entire adjustment

range of switch.

4. Retest the set point several times to ensure accuracy of

setting.

5. Re-seat locking screw.

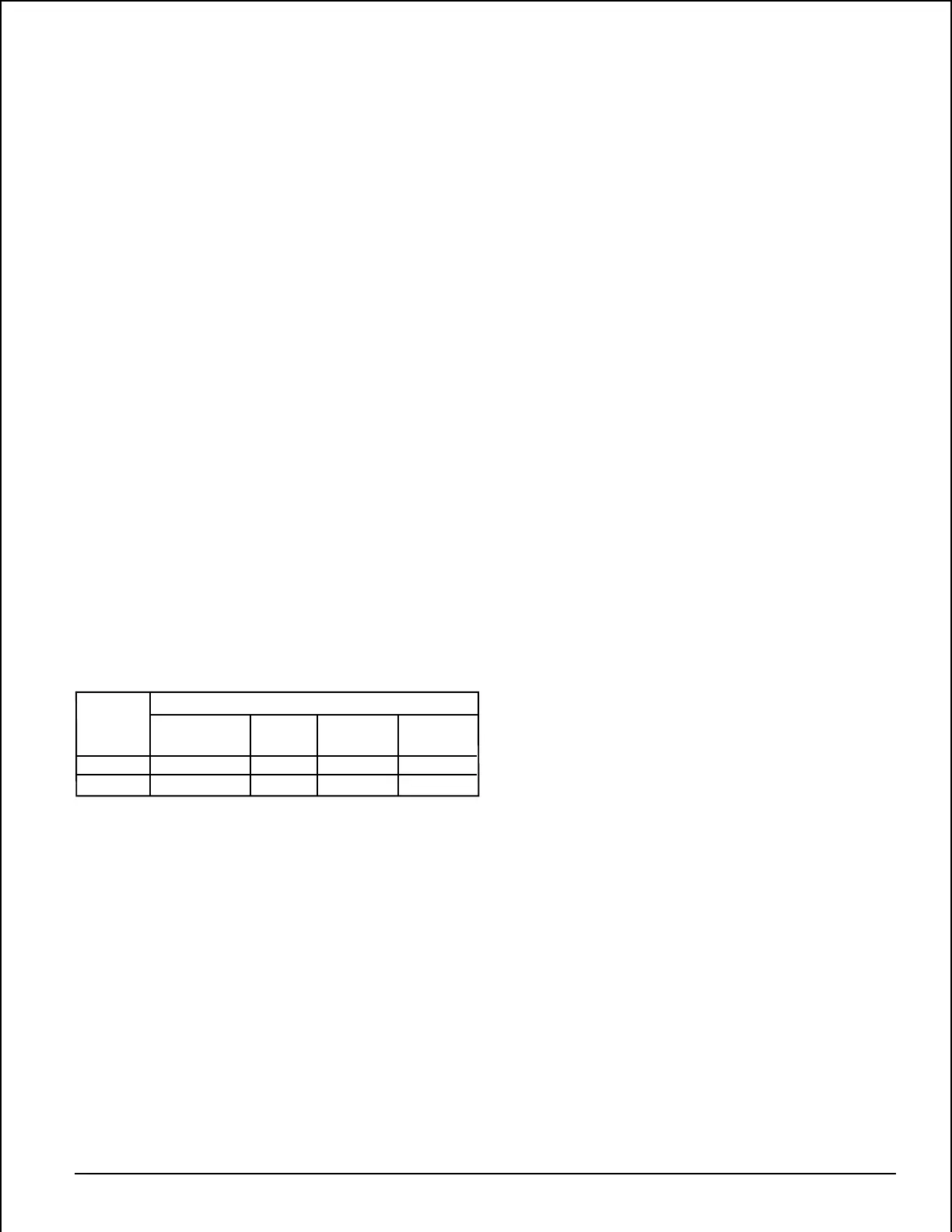

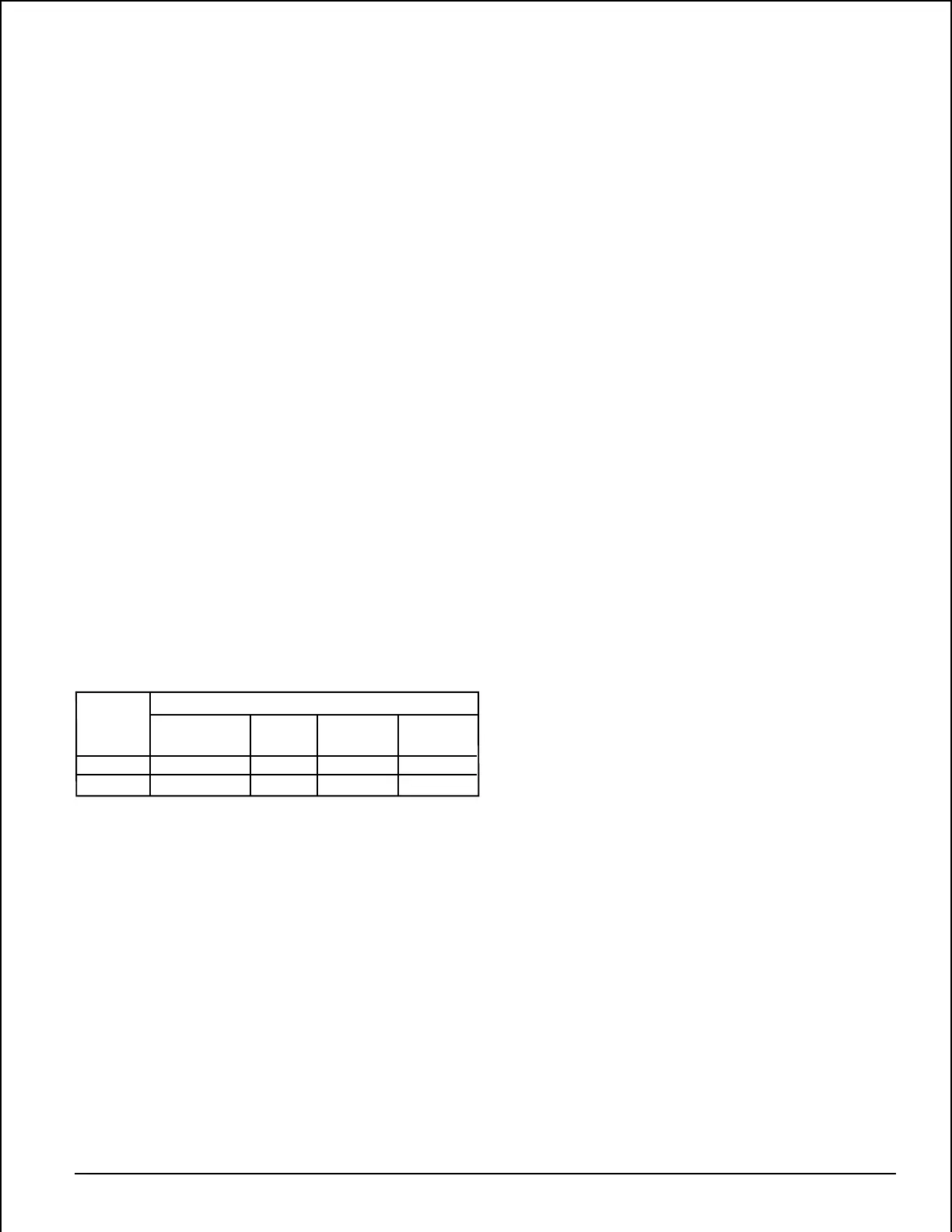

Table 2.

FACTORY SETTINGS (PSI)

MODEL

Fall

(Low Switch)

Approx.

Reset

Rise

(Hi Switch)

Approx.

Reset

EPS10-1

EPS10-2

–– ––

––––

3 PSI Diff.

3 PSI Diff.4– 8

4– 8

NOTE: The sensor assembly is not field replaceable. Do

not attempt to disassemble these parts. If you have

any questions, consult System Sensor. System Sen-

sor recommends careful consideration of the fol-

lowing factors when specifying and installing

Alarm Pressure Switches. Always refer to the In-

stallation and Maintenance Instruction for spe-

cific recommendations on individual devices

before installing the unit.

• Electrical ratings stated in literature and on name-

plates should not be exceeded.

• Overload on switch can cause failure on the first

cycle. Always wire devices according to national and

local electrical codes.

• Install units away from shock and vibration. Proper

electrical fittings should be used to prevent moisture

from entering the enclosure via the conduit.

• Test all devices for proper operation after initial instal-

lation. Perform preventive maintenance and periodic

testing as required by the applicable NFPA standards

but not less than bi-monthly.

• Install a back-up control for all critical applications

where control failure could endanger life or property.

A backup control to serve as a high or low limit con-

trol is especially recommended for applications where

a runaway condition could result.

• Do not mount unit where ambient temperatures will

exceed published limits.

• Avoid impact or mechanical loading.

Technical Manuals Online! - http://www.tech-man.com

Loading...

Loading...